Electric Actuators

» Slider Type Series LEFS/LEFB - Product Features

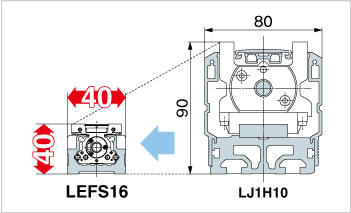

Compact

Height/width dimensions reduced by approx. 50%

* Compared with SMC LJ1 series

(Work load: 10 kg)

Easy mounting of the body/

Reduction of the installation labor

Reduction of the installation labor

Possible to mount the main body without removing

the external cover, etc.

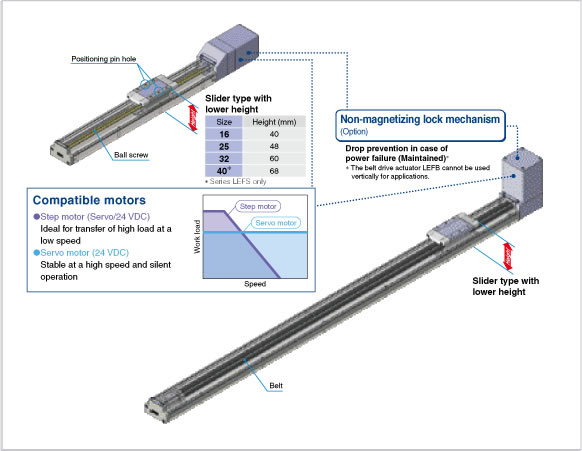

Actuation type selectable

| Ball Screw Drive Series LEFS / Size: 16, 25, 32, 40

Ball Screw Drive Series LEFS / Size: 16, 25, 32, 40

- Max. work load: 65 kg

- Max. speed: 1,200 mm/s

- Positioning repeatability: ±0.02 mm

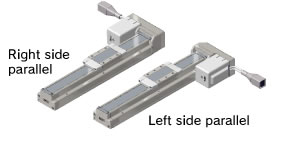

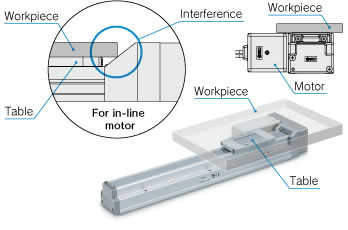

- Motor parallel type available!

◎Motor mounting position can be selected

from two directions (Right or Left).

◎Top surface of table and motor are level.

| Ball Screw Drive Series LEFS / Size: 25, 32, 40

Ball Screw Drive Series LEFS / Size: 25, 32, 40

- High output motor

(100 W/200 W/400 W) - Improved high speed transfer ability

- High acceleration/deceleration compatible (5,000 mm/s2)

- Pulse input type

- With internal absolute encoder

(For LECSB)

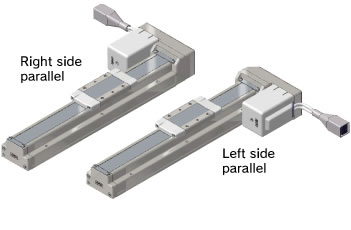

- Motor parallel type available!

◎Motor mounting position can be selected from two directions (Right or Left).

| Belt Drive Series LEFB / Size: 25, 32, 40

Belt Drive Series LEFB / Size: 25, 32, 40

- Max. speed: 2,000 mm/s

- Max. stroke: 3,000 mm

- Max. acceleration/deceleration: 20,000 mm/s2

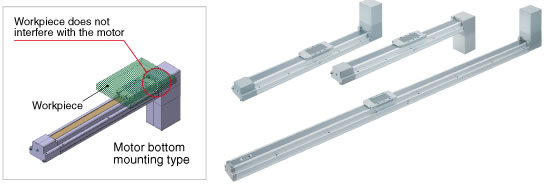

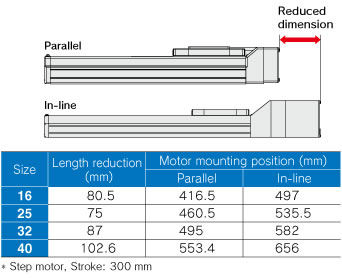

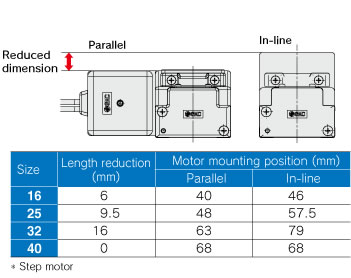

|Motor Parallel Type Series LEFS□R

■Reduced in overall length

■Reduced in height

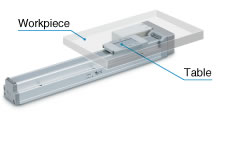

■Top surface of table and

motor are level.

■Motor mounting position can be selected from two directions.

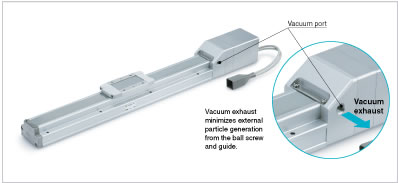

Clean Room Specification Ball Screw Drive Series 11-LEFS

ISO Class 4 *1 (ISO14644-1)

- Built-in vacuum piping

- Possible to mount the main body without removing the external cover, etc.

- Body-integrated linear guide specification

*1 Changes depending on the suction flow rate.

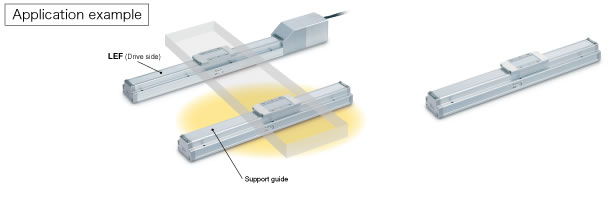

|Support Guide / Series LEFG

A support guide is designed to support work pieces with significant overhang.

- As the dimensions are the same as the LEF series body, installation is simple and contributes to a reduction in installation and assembly labor.

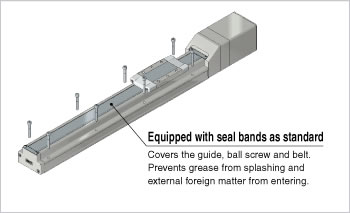

- The standard equipped seal bands prevent grease from splashing and external foreign matter from entering.