There were 709 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

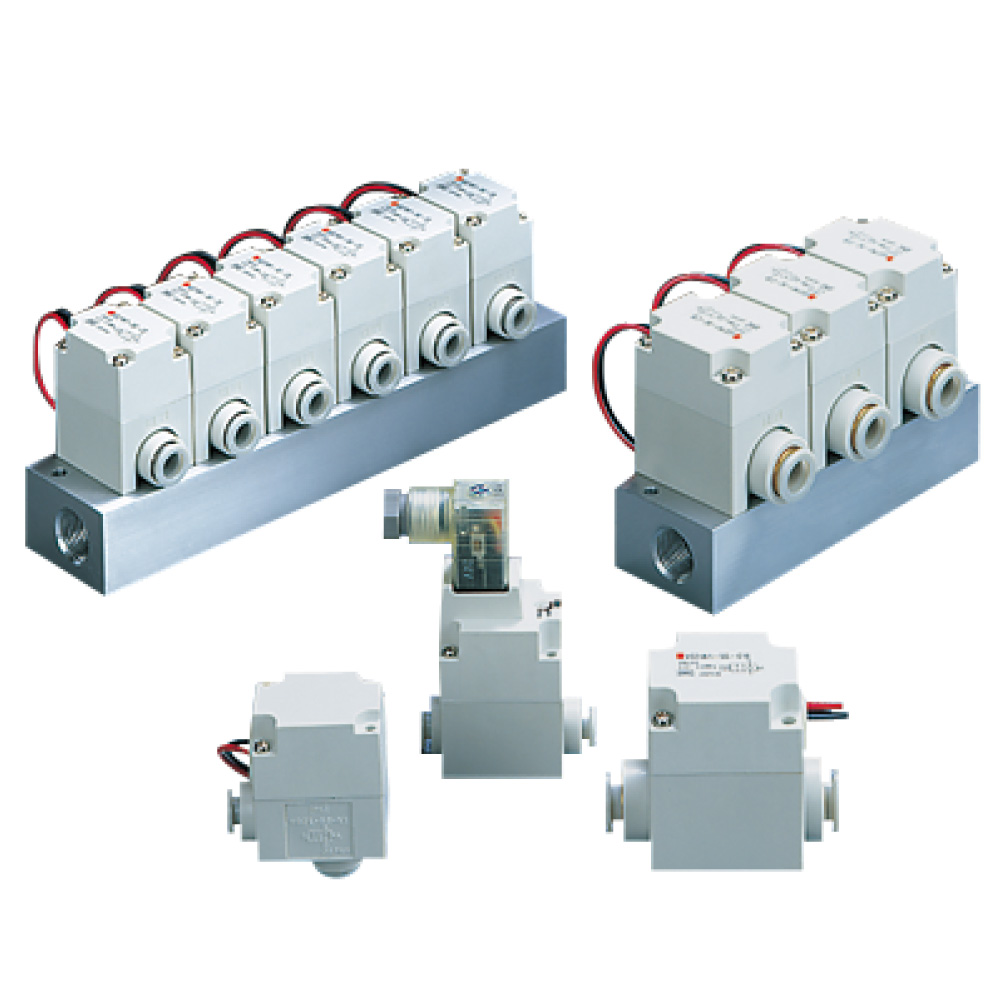

Normal Close High Vacuum Solenoid Valve XSA

Process Valves » Compact 2/3 Port Solenoid Valves/Air Operated ValvesHigh Vacuum Equipment » High Vacuum Valves

Equipment for the Semiconductor Industries » Exhaust Line

Equipment for the Semiconductor Industries » N2 Gas/Air Supply Line

-

・Minimum operating pressure: 1 × 10-6 Pa (abs)

・Leakage: Internal 1.3 × 10-9 Pa·m3/s, External 1.3 × 10-11 Pa·m3/s

・2 types of fittings and female threads are available.

・Power consumption: Max. 25% reduction

・Weight: Max. 18% lighter (0.5 kg → 0.41 kg)

Safety Instructions System Configuration/Role of Each Line and Component Series Variations Glossary Auto Switches Common Specifications Green Procurement (RoHS)

| Series | Valve type | Fluid | Piping | Port size |

|---|---|---|---|---|

| XSA | Normally closed | Air Inert gas | Face seal fitting Compression fitting | 1/4, 3/8 |

| XSA | Normally closed | Air Inert gas | Rc, NPT female thread | 1/8, 1/4, 3/8 |

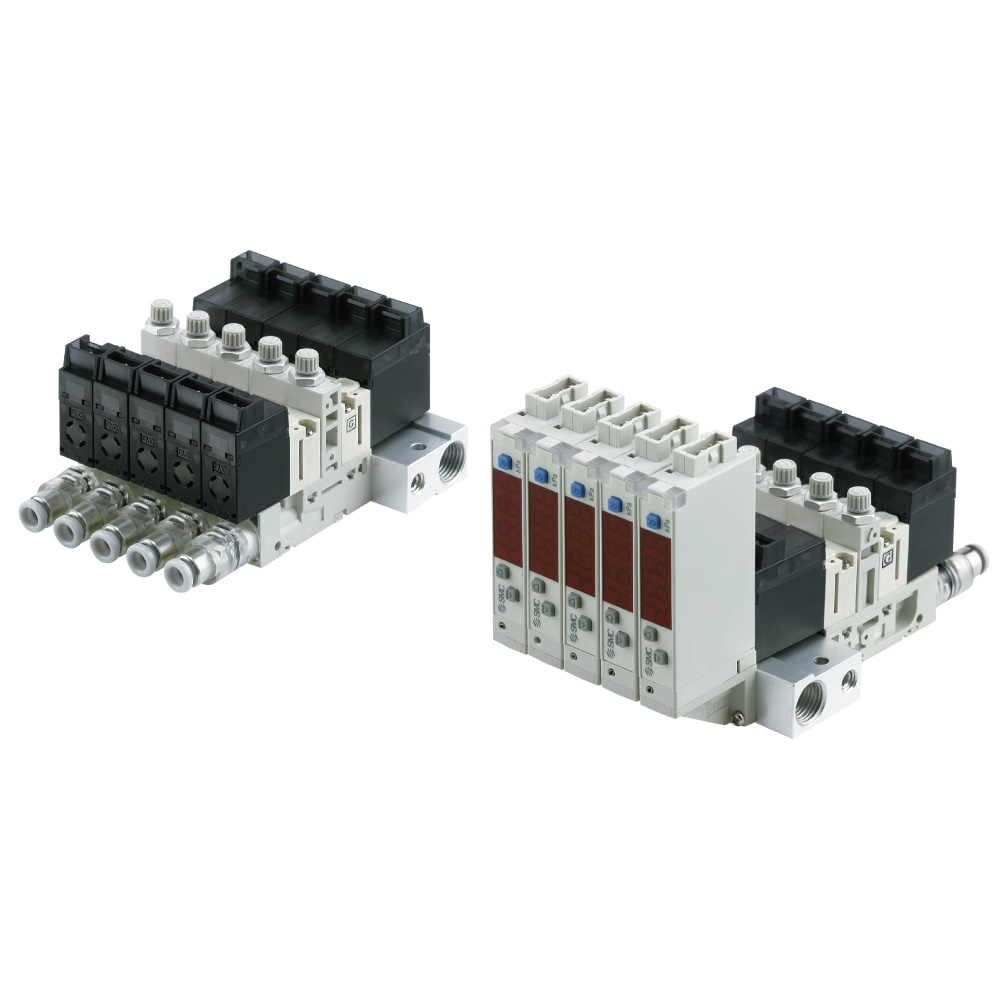

Pilot Operated 2 Port Solenoid Valve (2 Way Valve) for Dry Air

VQ

Process Valves » Compact 2/3 Port Solenoid Valves

-

・High-frequency operation is possible: High-speed response 7 ms or less (VQ20), 20 ms or less (VQ30)

・Easy piping with One-touch fittings

・The dust-tight, water-jet-proof enclosure (IP65) is compatible with the DIN terminal type.

・Applications: Air-blow, Blow-off of workpieces, etc.

・Manifold type no.: VV2Q22, VV2Q32

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics Series Variations/Solenoid Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics Series Variations/Solenoid Valves List

Green Procurement (RoHS)

| Series | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|

| VQ20 | N.C. | φ6 to φ12 | 3.4 |

| VQ30 | N.C. | φ6 to φ12 | 4.8 |

3-Screen Display Digital Gap Checker/IO-Link Compatible ISA3-L

Switches/Sensors/Controller » Electronic Pressure Switches/Sensors (Self-contained Type)IO-Link Devices » Pressure Switches

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: IO-Link Compatible Products

-

・Monitoring the placement condition of the workpiece Indicates failure/abnormality

・Double sensor providing improved preventive and predictive maintenance (IoT) based on IO-Link

Process data provides Displayed value, Outlet pressure, and Supply pressure value.

・NPN/PNP switch function

・3-screen display (Setting)

・Window comparator type

・Zero cut-off range can be changed.

▶IO-Link Master

Safety Instructions Pressure Switches/Flow Switches/Precautions

Pressure Switch Series Variations/Application Example Glossary of Terms/Technical Information

Green Procurement (RoHS) IO-Link Master

Pressure Switch Series Variations/Application Example Glossary of Terms/Technical Information

Green Procurement (RoHS) IO-Link Master

| Series | Rated distance range | Piping specifications: Supply side | Piping specifications: Detection side |

|---|---|---|---|

| ISA3-F□L | 0.01 to 0.03 mm | Rc, G 1/8 | φ4, φ6 One-touch fitting, G 1/8 |

| ISA3-G□L | 0.02 to 0.15 mm | Rc, G 1/8 | φ4, φ6 One-touch fitting, G 1/8 |

| ISA3-H□L | 0.05 to 0.30 mm | Rc, G 1/8 | φ4, φ6 One-touch fitting, G 1/8 |

Compact Vacuum Unit (Vacuum Generators) ZB

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump SystemsIO-Link Devices » Vacuum Manifold

-

・Compatible with ejector systems and vacuum pump systems

・Quick response: Response time of the valve 5 ms, vacuum response time

28 ms

・Energy saving: Air consumption reduced by 17%, Vacuum pressure

reached increased by 21%

・Compact/Lightweight: 46 g

・With vacuum pressure switch

Can copy to up to 10 switches simultaneously

・IO-Link compatible

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZB03 | 0.3 | 2 | 3.5 | 2 to 8 | ZB00 |

| ZB04 | 0.4 | 3.5 | 6.5 | 2 to 10 | ZB00 |

| ZB05 | 0.5 | 4.5 | 10 | 2 to 13 | ZB00 |

| ZB06 | 0.6 | 7 | 18 | 2 to 20 | ZB00 |

Electric Actuator/Rod Type LEY

Electric Actuators/Cylinders » Motorless Type-

・Various servo motors can be mounted due to the addition of the motorless type.

・Compatible motors:

Mitsubishi Electric Corporation, YASKAWA Electric Corporation,

SANYO DENKI CO., LTD., OMRON Corporation, Panasonic Corporation,

FANUC CORPORATION, NIDEC INSTRUMENTS,

KEYENCE CORPORATION, FUJI ELECTRIC CO., LTD., MinebeaMitsumi Inc.,

Shinano Kenshi Co., Ltd., ORIENTAL MOTOR Co., Ltd., FASTECH Co., Ltd.,

Rockwell Automation, Inc. (Allen-Bradley), Beckhoff Automation GmbH,

Siemens AG, Delta Electronics, Inc., ANCA Motion

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

| Specification | Model | Stroke (mm) | Pushing force (N) | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Motorless Top/Parallel | LEY25 | 30 to 400 | Max. 485 | Max. 900 | 3, 6, 12 |

| Motorless In-line | LEY25D | 30 to 400 | Max. 485 | Max. 900 | 3, 6, 12 |

| Motorless Top/Parallel | LEY32 | 30 to 500 | Max. 588 | Max. 1200 | 4, 8, 16 |

| Motorless In-line | LEY32D | 30 to 500 | Max. 736 | Max. 1000 | 4, 8, 16 |

| Motorless Top/Parallel | LEY63 | 50~800 | MAX.3343 | MAX.1000 | 5, 10, 20 |

| Motorless In-line | LEY63D | 50 to 800 | Max. 1910 | Max. 1000 | 5, 10, 20 |

| Motorless Top/Parallel | LEY100 | 100~1000 | MAX.12000 | MAX.500 | 10 |

| Motorless In-line | LEY100D | 100 to 1000 | Max. 12000 | Max. 500 | 10 |

Electric Actuator/Guide Rod Type, In-line Motor Type LEYG□D

Electric Actuators/Cylinders » Rod Type/Guide Rod Type

-

Series LEYG Step Motor (Servo/24 VDC) Servo Motor (24 VDC)

・Compact integration of guide rods

Achieves lateral load resistance and high non-rotating accuracy.

・Lateral end load: 5 times more (compared with rod type, size 25 and 100 stroke)

・Compatible with sliding bearing and ball bushing bearing.

Compatible with moment load and stopper (sliding bearing).

・Speed control/Positioning: Max. 64 points

・Positioning and pushing control can be selected.

Possible to hold the actuator when pushing the rod to a workpiece, etc.

・Positioning repeatability: ±0.02 mm or less

Series LEY AC Servo Motor

・High output motor (100/200 W)

・Improved high speed transfer ability

・High acceleration/deceleration compatible (5,000mm/s2)

・Pulse input type

・With internal absolute encoder

・Motorless specification is available. Click here for details

・Compatible drivers: Click here for LECSS-T,LECY□

Safety Instructions Electric Actuators/Precautions Features Series Variations

Simplified Selection Flow Chart Green Procurement (RoHS) CE/UL-compliance List

Simplified Selection Flow Chart Green Procurement (RoHS) CE/UL-compliance List

| Spec. | Model | Stroke (mm) | Pushing force [N] | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Step motor (Servo/24 VDC) | LEYG16D | 30 to 200 | Max. 141 | Max. 500 | 2.5,5,10 |

| Step motor (Servo/24 VDC) | LEYG25D | 30 to 200 | Max. 452 | Max. 500 | 3,6,12 |

| Step motor (Servo/24 VDC) | LEYG32D | 30 to 200 | Max. 707 | Max. 500 | 4,8,16 |

| Step motor (Servo/24 VDC) | LEYG40D | 30 to 200 | Max. 1058 | Max. 300 | 4,8,16 |

| Servo motor (24 VDC) | LEYG16DA | 30 to 200 | Max. 111 | Max. 500 | 2.5,5,10 |

| Servo motor (24 VDC) | LEYG25DA | 30 to 300 | Max. 130 | Max. 500 | 3,6,12 |

| AC servo motor | LEYG25DS | 30 to 300 | Max. 485 | Max. 900 | 3,6,12 |

| AC servo motor | LEYG32DS | 30 to 300 | Max. 736 | Max. 1000 | 4,8,16 |

Electric Actuator/High Rigidity Slider Type Ball Screw Drive

LEJS63□-□M

Electric Actuators/Cylinders » Slider Type-

・Built-in intermediate supports

・A maximum speed of 1,800 mm/s has been achieved throughout the

entire stroke!

The use of intermediate supports results in reduced deflection of the ball

screw when a long stroke is used.

・Max. stroke: 1,790 mm

・Horizontal work load: 85 kg

・Positioning repeatability: ±0.01 mm (High-precision type)

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS) CE/UL-compliance List

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS) CE/UL-compliance List

| Specification | Series | Stroke (mm) | Work load (kg) Horizontal | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| AC servo motor | LEJS63□-□M | 790 to 1790 | Max. 85 | Max. 1800 | 10,20,30 |

Air Gripper Unit for Collaborative Robots JMHZ2-X7400B-DTP/HC10DT/HC10

for the YASKAWA Electric Corporation MOTOMAN-HC

Rotary Actuators/Air Grippers » Air Gripper Unit for Collaborative Robots-

・Compact, lightweight product with high gripping force due to air operation

・1 air supply tube and the electric wiring can be operated simply by connecting the annex cable.

・Integrated solenoid valve, speed adjustment mechanism, and auto switch

・High rigidity and high precision due to its guide-integrated construction

Repeatability: ±0.01 mm due to the adoption of a high-precision linear guide

Higher rigidity due to the adoption of a linear guide of the higher rigidity and precision

・A split protective cover for easy air gripper maintenance

| Type | Series | Cylinder bore size (mm) |

|---|---|---|

| For Collaborative Robots | JMHZ2-16D-X7400B-DTP JMHZ2-16D-X7400B-HC10 JMHZ2-16D-X7400B-HC10DT | 16 |

Centering Unit MACM

Air Cylinders » Pin Shift Cylinder

-

・Alignment and positioning of transferred workpieces

Contributes to space saving on conveyor lines

・Table

Max. allowable load weight: 1000 kg (MACM10)

Workpieces can be moved in any direction: forward/backward, right/left, at an angle, and even rotated (360º).

Ball bearings allow for smooth operation.

Table centering accuracy ±1 mm or less (Workpiece not loaded)

Table center movable range Max. ø100 mm (MACM10-50)

| Series | Action | Max. allowable load weight kN | Stroke (mm) |

|---|---|---|---|

| MACM | Double acting | 2, 4, 6, 10 | 12, 20, 30, 50 |

Clamp Cylinder/Slim Type C(L)KG/C(L)KP-X2095

Air Cylinders » Clamp Cylinders

-

・ø25 is available.

Weight: 380 g, Length: 186.7 mm

(ø25-50 stroke without speed controller or auto switch)

・Weight reduced by up to 48%, total length reduced by 18%

Safety Instructions Actuators/Precautions

Auto Switches/Precautions Model Selection/Technical Data

Green Procurement (RoHS)

Auto Switches/Precautions Model Selection/Technical Data

Green Procurement (RoHS)

| Type | Series | Action | Clevis width (mm) | Bore size (mm) |

|---|---|---|---|---|

| Standard (Built-in standard magnet) | CKG-X2095 | Double acting, Single rod | 9, 12 | 25, 32, 40 |

| Standard (Built-in strong magnet) | CKP-X2095 | Double acting, Single rod | 9, 12 | 25, 32, 40 |

| With lock (Built-in standard magnet) | CLKG-X2095 | Double acting, Single rod | 9, 12 | 25, 32, 40 |

| With lock (Built-in strong magnet) | CLKP-X2095 | Double acting, Single rod | 9, 12 | 25, 32, 40 |