There were 162 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Adsorption Plate SP

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Related Equipment for Vacuum Systems

-

・Ideal for the adsorption and fixing in place of thin sheets, glass panels, and soft workpieces

Workpieces will not be deformed since they are adsorbed with multiple micro air vents on the adsorption surface.

・A high level of machining accuracy

・Strong adsorption force

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Shape | Adsorption surface size | Sintered metallic element particle dia. | Suction port |

|---|---|---|---|---|

| SP | Rectangular, Square | □50 x 50 mm, □100 x 100 mm, □150 x 150 mm □200 x 200 mm, □250 x 250 mm, □300 x 300 mm | φ0.3 (Sphere) | 1/8 |

Vacuum Saving Valve ZP2V

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Saving Valves-

・Can restrict the reduction of vacuum pressure even when there is no workpiece

・A switching operation is not required when changing workpieces.

・Built-in filter (40 μm)

・With One-touch fittings

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

Bernoulli Gripper ZNC

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Special Pads-

・For the adsorption transfer of thin cloths, films, printed circuit boards,

etc.

・Energy saving: Max. 79% reduction (Comparison of air consumption

to lifting force)

・High lifting force: 65 N

10.3 times that of the existing model (Existing model: 6.3 N → ZNC80:

65 N)

・3 types of body materials: Aluminum, Resin, Stainless steel

・Attachments

With stopper: Prevents workpiece slippage

With vibration suppression cover: Suppresses the vibration noise of thin

workpieces

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Material | Size | Attachment |

|---|---|---|---|

| ZNC | Aluminum Resin Stainless steel | ø20, ø30, ø40, ø60, ø80 | With stopper With vibration suppression cover |

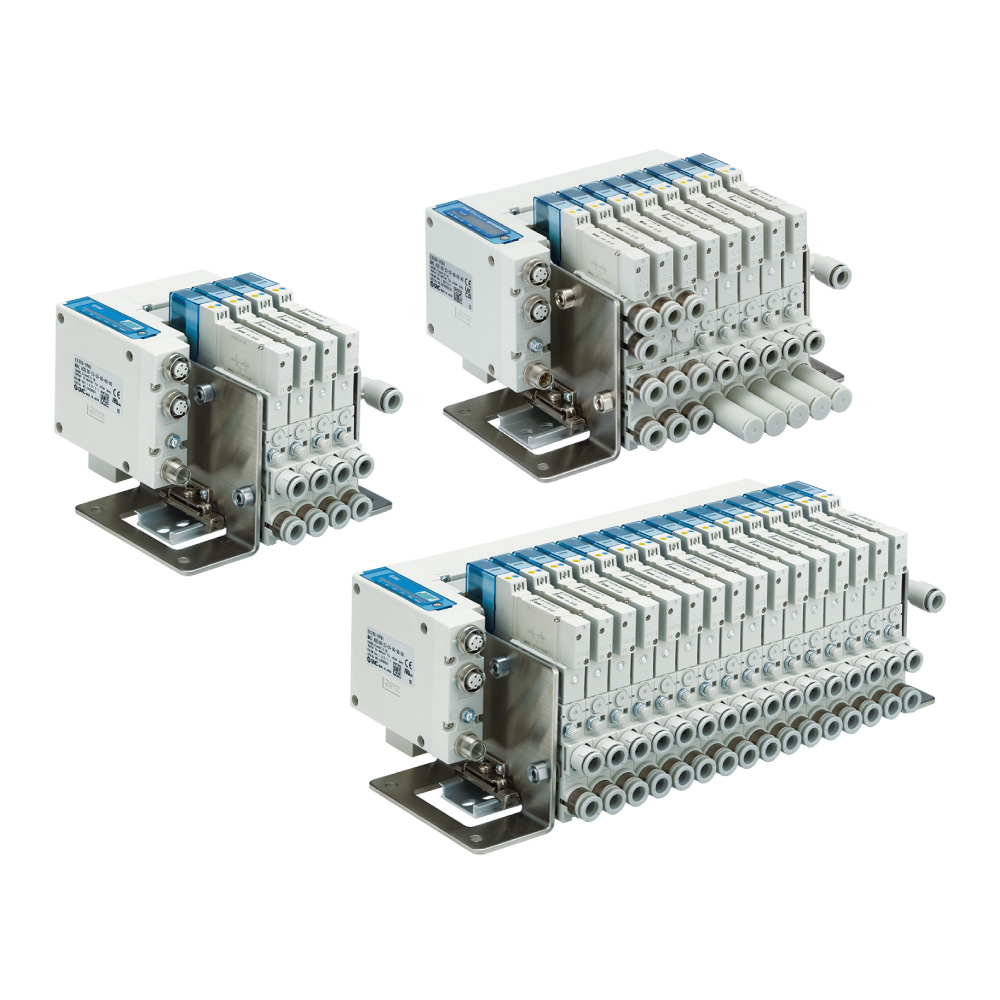

Vacuum Manifold for Fieldbus System ZKJ

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump SystemsIndustrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: PROFINET Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherNet/IP Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: IO-Link Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherCAT Compatible Products

IO-Link Devices » Vacuum Unit/Vacuum Manifold

-

・Vacuum pads and actuator driving can be controlled with a single

manifold [New]

・Positive pressure unit [New]

5-port solenoid valve

・Vacuum unit

Energy saving ejector Air consumption: 92% reduction

・Fieldbus compatible

Space saving: Requires no separate input/output units

Reduced wiring time

Compatible protocols: PROFINET, IO-Link, EtherNet/IP, EtherCAT

・Exhaust sealing function

Quick workpiece release

・4 stations/8 stations/12 stations/16 stations manifold compatible

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|

| ZKJ07 | 0.7 | 31 | 26 |

| ZKJ10 | 1.0 | 53 | 48 |

| ZKJ12 | 1.2 | 63 | 68 |

| ZKJ15 | 1.5 | 74 | 102 |

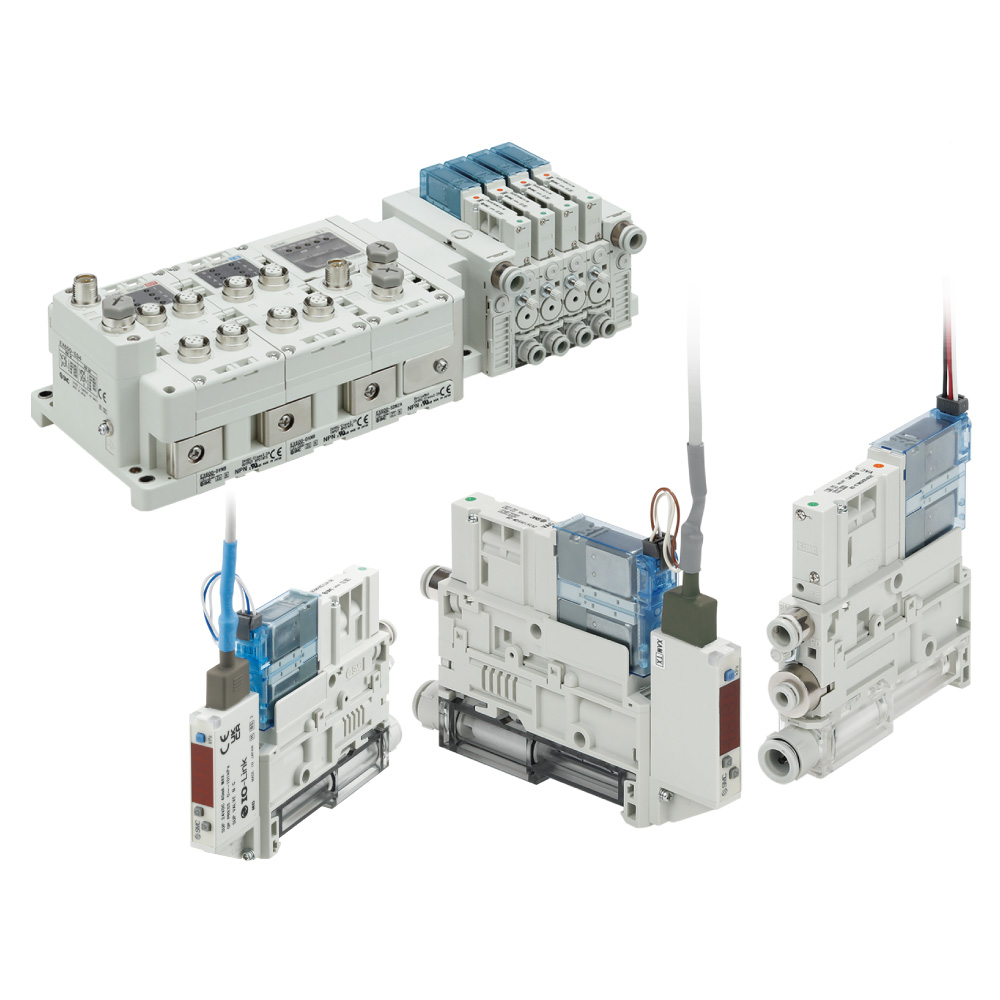

Vacuum Unit (Vacuum Generators) ZK2□A

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems-

・Supply valve: An N.O. specification has been added.

Can hold vacuum∗ even when the power goes out or is turned off

Prevents the sudden dropping of workpieces∗

∗ Supposing the supply pressure is being maintained

・An IO-Link compatible pressure switch has been added.

Allows for ejector control with a single communication line

Reading of the device information and parameter batch settings are

possible.

・Compatible with ejector systems and vacuum pump systems

・Energy saving ejector

Air supply is cut-off when vacuum is reached.

Air consumption: 93% reduction (Under SMC’s measurement conditions)

・More efficient ejector: Suction flow increased by 50% (Compared to other

SMC 1-stage ejectors)

・Energy saving efficiency: 93% reduction

・Improved low noise and suction flow by adoption of a high-noise

reduction silencer

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZK2□07 | 0.7 | 29 | 24 | 2 to 40 | ZK2□00 |

| ZK2□10 | 1.0 | 44 | 40 | 2 to 50 | ZK2□00 |

| ZK2□12 | 1.2 | 61 | 58 | 2 to 125 | ZK2□00 |

| ZK2□15 | 1.5 | 67 | 90 | 2 to 150 | ZK2□00 |

Electric Slide Table/Compact Type LES

Electric Actuators/Cylinders » Slide Tables

-

・Compact: Workpiece mounting surface height reduced by up to 12% compared with the LESH

・Vertical work load: Increased by up to 50%

・Lightweight: Reduced by up to 29%

・Max. pushing force: 180 N

・Positioning repeatability: ±0.05 mm

・Cycle time can be reduced.

Max. acceleration/deceleration: 5,000 mm/s2

Max. speed: 400 mm/s

Safety Instructions Electric Actuators/Precautions Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS) CE/UL-compliance List Actuator Cable I/O Cable

| Specification | Model | Stroke (mm) | Work load (kg) Horizontal | Work load (kg) Vertical | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|---|

| Step motor (Servo/24 VDC) | LES8□ | 30,50,75 | Max. 1 | Max. 0.5 | Max. 400 | 4 ,8 |

| Step motor (Servo/24 VDC) | LES16□ | 30,50,75,100 | Max. 3 | Max. 3 | Max. 400 | 5,10 |

| Step motor (Servo/24 VDC) | LES25□ | 30,50,75,100,125,150 | Max. 5 | Max. 5 | Max. 400 | 8,16 |

| Servo motor (24 VDC) | LES8□A | 30,50,75 | Max. 1 | Max. 1 | Max. 400 | 4,8 |

| Servo motor (24 VDC) | LES16□A | 30,50,75,100 | Max. 3 | Max. 3 | Max. 400 | 5,10 |

| Servo motor (24 VDC) | LES25□A | 30,50,75,100,125,150 | Max. 5 | Max. 4 | Max. 400 | 8,16 |

Electric Actuator/Rod Type, Motor Top/Parallel Type LEY

Electric Actuators/Cylinders » Rod Type/Guide Rod Type

-

LEY Series Step Motor (Servo/24 VDC), Servo Motor (24 VDC)

・Long stroke: Max. 500 mm

・Direct mounting: 3 directions, Bracket mounting: 3 types

・Auto switch can be mounted.

・Speed control/Positioning: Max. 64 points

・Either positioning or pushing control can be selected.

It is possible to hold the actuator with the rod pushing on a workpiece, etc.

・Positioning repeatability: ±0.02 mm or less

・Dust-tight/Water-jet-proof (IP65)

LEY Series AC Servo Motor

・High output motor (100/200/400 W)

・Improved high speed transfer ability

・High acceleration compatible (5000 mm/s2)

・Pulse input type

・With internal absolute encoder

・Positioning repeatability: ±0.02 mm or less

・Dust-tight/Water-jet-proof (IP65 equivalent)

・Motorless specification is available. Click here for details

・Compatible drivers: Click here for LECSS-T,LECY□

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

CE/UL-compliance List Actuator Cable I/O Cable

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

CE/UL-compliance List Actuator Cable I/O Cable

| Specification | Model | Stroke (mm) | Pushing force (N) | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Step motor (Servo/24 VDC) | LEY16 | 30 to 300 | Max. 141 | Max. 500 | 2.5,5,10 |

| Step motor (Servo/24 VDC) | LEY25 | 30 to 400 | Max. 452 | Max. 500 | 3,6,12 |

| Step motor (Servo/24 VDC) | LEY32 | 30 to 500 | Max. 707 | Max. 500 | 4,8,16 |

| Step motor (Servo/24 VDC) | LEY40 | 30 to 500 | Max. 1058 | Max. 300 | 4,8,16 |

| Servo motor (24 VDC) | LEY16A | 30 to 300 | Max. 111 | Max. 500 | 2.5,5,10 |

| Servo motor (24 VDC) | LEY25A | 30 to 400 | Max. 130 | Max. 500 | 3,6,12 |

| AC servo motor | LEY25□S | 30 to 400 | Max. 485 | Max. 900 | 3,6,12 |

| AC servo motor | LEY32□S | 30 to 500 | Max. 588 | Max. 1200 | 5,10,20 |

| AC servo motor | LEY63□S | 100 to 800 | Max. 3343 | Max. 1000 | 5 (2.86),5,10,20 |

| AC servo motor | LEY100 | 100 to 1000 | MAX.12000 | MAX.500 | 2,3.3,10 |

For High Precision Positioning: Pin Shift Cylinder CKQG-X2370/CKQP-X2371

Air Cylinders » Pin Shift Cylinder-

・High Precision: Rod end deflection of ±0.1 mm or less

・Position reproducibility

・Pins for positioning the workpiece provided by the customer can be directly mounted.

・Built-in coil scraper

・Reduces labor time by integrating the cylinder and guide

・Magnetic field resistant auto switches are mountable.

| Type | Series | Bore size (mm) | Stroke (mm) |

|---|---|---|---|

| Built-in standard magnet | CKQG-X2370 | 32, 40, 50 | 25, 30, 40, 50 |

| Built-in strong magnet | CKQP-X2371 | 50 | 30, 50 |

Sine Rodless Cylinder REA

Air Cylinders » Specialty Cylinders

-

・Allows the high-speed transfer of a workpiece which must avoid shock/impact

・Maximum speed: 300 mm/s

Safety Instructions Actuators/Precautions Auto Switches/Precautions

Model Selection/Technical Data Made to Order Common Specifications

Green Procurement (RoHS)

Model Selection/Technical Data Made to Order Common Specifications

Green Procurement (RoHS)

| Type | Series | Action | Bore size (mm) |

|---|---|---|---|

| Basic | REA | Double acting | 25,32,40,50,63 |

| Direct mount | REAR | Double acting | 10,15,20,25,32,40 |

| Slider (Slide bearing) | REAS | Double acting | 10,15,20,25,32,40 |

| Slider (Ball bushing bearing) | REAL | Double acting | 10,15,20,25,32,40 |

| Linear guide (Single axis) | REAH | Double acting | 10,15,20,25 |

| Linear guide (Double axis) | REAHT | Double acting | 25,32 |

Vacuum/Release Unit VQD1000-V

Directional Control Valves » Direct Operated 3/4/5 Port Solenoid ValvesVacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Release Valve Units

-

・Applicable to 0603 chips

・Response speed: 13 msec (at the time of 500 mm*) /18.5 msec (at the time of 1000 mm*)

・Smooth workpiece removal with no overshoot

・There is no need for timing adjustment of switchback between vacuum and positive pressure.

・A throttle circuit is not required for release air.

・Suction filter: ZFC050 (Made to order)

* Distance from the unit to the work area

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)