There were 162 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Vacuum Gripper for Collaborative Robots ZXP7□12-X1□/ZXP7□11-X1□

for YASKAWA Electric Corporation collaborative robot MOTOMAN-HC10DT

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Gripper for Collaborative RobotsAir Gripper for Collaborative Robots » Vacuum Grippers

-

・Can be operated simply by connecting 1 compressed air supply tube and the built-in cable for electric wiring

・Integrated vacuum ejector, air supply/release valve, pressure switch, and cups

・As the air piping and electric wiring built into the robot are used, no external wiring or piping is required.

No interference with workpieces or workers

・Features a rounded appearance without corners

・A wide variety of cup variations are available to support a wide range of workpieces.

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Cup form | Cup diameter | Suction flow rate [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|---|

| ZXP7□12-X1□ ZXP7□11-X1□ | Flat Flat with rib Bellows Thin flat Multistage bellows 2.5-stage bellows 5.5-stage bellows | φ8 to φ32 | 17 | 57 |

Electric Actuator/Guide Rod Type, In-line Motor Type LEYG□D

Electric Actuators/Cylinders » Rod Type/Guide Rod Type

-

Series LEYG Step Motor (Servo/24 VDC) Servo Motor (24 VDC)

・Compact integration of guide rods

Achieves lateral load resistance and high non-rotating accuracy.

・Lateral end load: 5 times more (compared with rod type, size 25 and 100 stroke)

・Compatible with sliding bearing and ball bushing bearing.

Compatible with moment load and stopper (sliding bearing).

・Speed control/Positioning: Max. 64 points

・Positioning and pushing control can be selected.

Possible to hold the actuator when pushing the rod to a workpiece, etc.

・Positioning repeatability: ±0.02 mm or less

Series LEY AC Servo Motor

・High output motor (100/200 W)

・Improved high speed transfer ability

・High acceleration/deceleration compatible (5,000mm/s2)

・Pulse input type

・With internal absolute encoder

・Motorless specification is available. Click here for details

・Compatible drivers: Click here for LECSS-T,LECY□

Safety Instructions Electric Actuators/Precautions Features Series Variations

Simplified Selection Flow Chart Green Procurement (RoHS) CE/UL-compliance List

Simplified Selection Flow Chart Green Procurement (RoHS) CE/UL-compliance List

| Spec. | Model | Stroke (mm) | Pushing force [N] | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Step motor (Servo/24 VDC) | LEYG16D | 30 to 200 | Max. 141 | Max. 500 | 2.5,5,10 |

| Step motor (Servo/24 VDC) | LEYG25D | 30 to 200 | Max. 452 | Max. 500 | 3,6,12 |

| Step motor (Servo/24 VDC) | LEYG32D | 30 to 200 | Max. 707 | Max. 500 | 4,8,16 |

| Step motor (Servo/24 VDC) | LEYG40D | 30 to 200 | Max. 1058 | Max. 300 | 4,8,16 |

| Servo motor (24 VDC) | LEYG16DA | 30 to 200 | Max. 111 | Max. 500 | 2.5,5,10 |

| Servo motor (24 VDC) | LEYG25DA | 30 to 300 | Max. 130 | Max. 500 | 3,6,12 |

| AC servo motor | LEYG25DS | 30 to 300 | Max. 485 | Max. 900 | 3,6,12 |

| AC servo motor | LEYG32DS | 30 to 300 | Max. 736 | Max. 1000 | 4,8,16 |

Rotary Gripper MRHQ

Rotary Actuators/Air Grippers » Angular Type Air Grippers

-

・The gripper function and the rotation function have been integrated in a compact package.

・It is possible to grip and reverse workpieces in conveyor lines with a single unit.

・Rotation range and angle are adjustable.

Safety Instructions Rotary Actuators/Precautions Air Grippers/Precautions

Auto Switches/Precautions Air Grippers Series Variations/Model Selection Green Procurement (RoHS)

Auto Switches/Precautions Air Grippers Series Variations/Model Selection Green Procurement (RoHS)

| Type | Series | Cylinder bore size (mm) |

|---|---|---|

| Standard | MRHQ | 10,16,20,25 |

| With dust cover | MRHQ-X11□ | 10,16,20,25 |

Air Gripper with Finger Changer Function MHF2-X7076A

Rotary Actuators/Air Grippers » Parallel Type Air Grippers-

・Automatic tool changer unit for robots

・The wiring and piping are bundled together in the body of the air gripper (robot side).

・Improves electric contact during tool changes, reduces air leakage due to defective piping connections, etc.

・Various workpieces can be handled by a single robot.

Increased productivity due to reduced attachment replacement and positioning work

・Overall length: Reduced by 82% or more

・Weight: Reduced by 69% or more (485 g → 150 g)

| Type | Series | Cylinder bore size (mm) |

|---|---|---|

| With finger changer function | MHF2-X7076A | 8 |

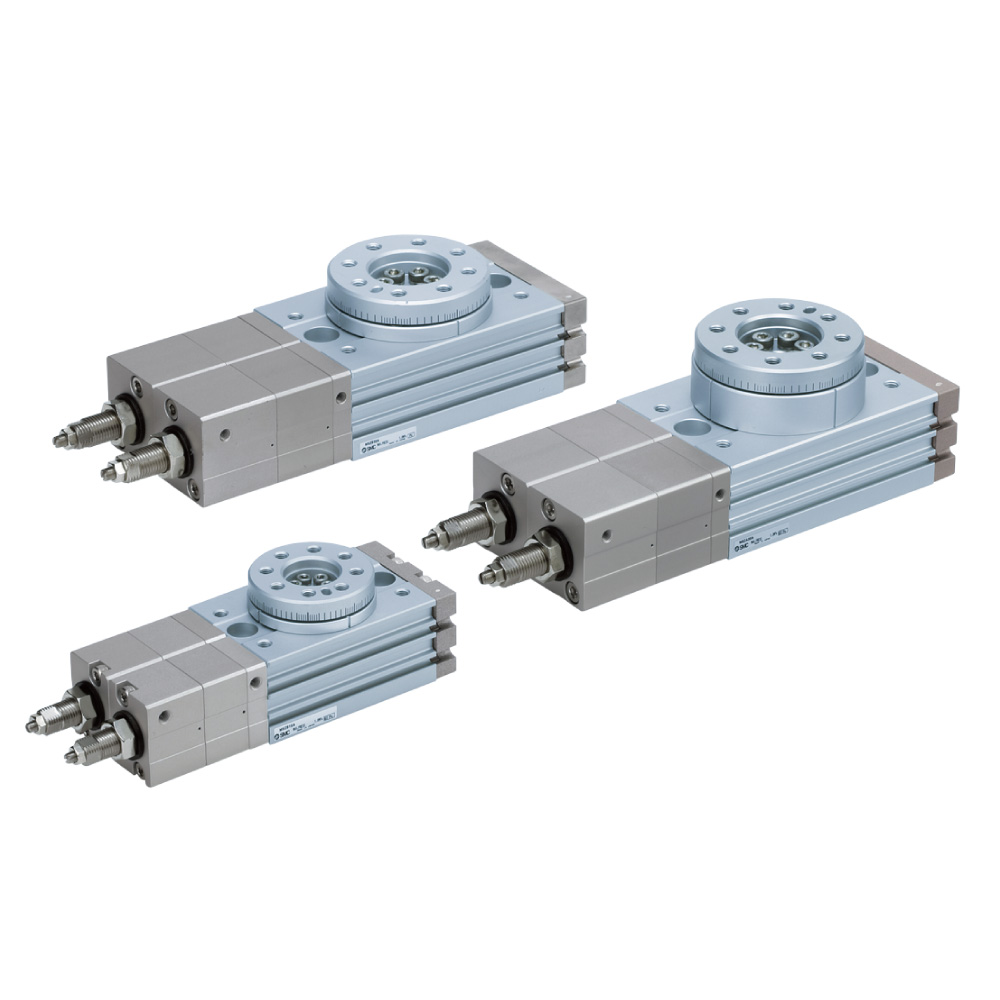

3-Position Rotary Table MSZ

Rotary Actuators/Air Grippers » Rotary Actuators Rack & Pinion Type

-

・3-point-stopping is possible.

・Suitable for applications such as distributing workpieces to the left, right, and center

・Can be operated with one valve

Safety Instructions Rotary Actuators/Precautions

Auto Switches/Precautions Rotary Actuators Series Variations/Model Selection

Green Procurement (RoHS)

Auto Switches/Precautions Rotary Actuators Series Variations/Model Selection

Green Procurement (RoHS)

| Type | Series | Rack type | Size | Stop position adjustment range |

|---|---|---|---|---|

| High precision type | MSZA | Double | 10,20,30,50 | Intermediate position: ±10° Rotating end: Left/right, both 0 to 95º using the intermediate position as a basis |

| Basic type | MSZB | Double | 10,20,30,50 | Intermediate position: ±10° Rotating end: Left/right, both 0 to 95º using the intermediate position as a basis |

Centering Unit MACM

Air Cylinders » Pin Shift Cylinder

-

・Alignment and positioning of transferred workpieces

Contributes to space saving on conveyor lines

・Table

Max. allowable load weight: 1000 kg (MACM10)

Workpieces can be moved in any direction: forward/backward, right/left, at an angle, and even rotated (360º).

Ball bearings allow for smooth operation.

Table centering accuracy ±1 mm or less (Workpiece not loaded)

Table center movable range Max. ø100 mm (MACM10-50)

| Series | Action | Max. allowable load weight kN | Stroke (mm) |

|---|---|---|---|

| MACM | Double acting | 2, 4, 6, 10 | 12, 20, 30, 50 |

Center Lock Unit MA331-X441

Air Cylinders » Pin Shift CylinderArc Welding Process Equipment » Specialty Cylinders

-

・The workpiece contact portion of the locating pin can switch from center lock (for locating) to free (for releasing workpieces).

・Even if the workpiece is distorted after welding, if the locating pin is set to free, the workpiece can be removed easily from the locating pin.

・Locating pin swing angle and rotation angle: 3° ±1°

| Series | Action | Handling air pressure |

|---|---|---|

| MA331-X441 | Double acting | 0.2 to 0.7 MPa |

Clamp Cylinder/Slim Type C(L)KG/C(L)KP-X2095

Air Cylinders » Clamp Cylinders

-

・ø25 is available.

Weight: 380 g, Length: 186.7 mm

(ø25-50 stroke without speed controller or auto switch)

・Weight reduced by up to 48%, total length reduced by 18%

Safety Instructions Actuators/Precautions

Auto Switches/Precautions Model Selection/Technical Data

Green Procurement (RoHS)

Auto Switches/Precautions Model Selection/Technical Data

Green Procurement (RoHS)

| Type | Series | Action | Clevis width (mm) | Bore size (mm) |

|---|---|---|---|---|

| Standard (Built-in standard magnet) | CKG-X2095 | Double acting, Single rod | 9, 12 | 25, 32, 40 |

| Standard (Built-in strong magnet) | CKP-X2095 | Double acting, Single rod | 9, 12 | 25, 32, 40 |

| With lock (Built-in standard magnet) | CLKG-X2095 | Double acting, Single rod | 9, 12 | 25, 32, 40 |

| With lock (Built-in strong magnet) | CLKP-X2095 | Double acting, Single rod | 9, 12 | 25, 32, 40 |

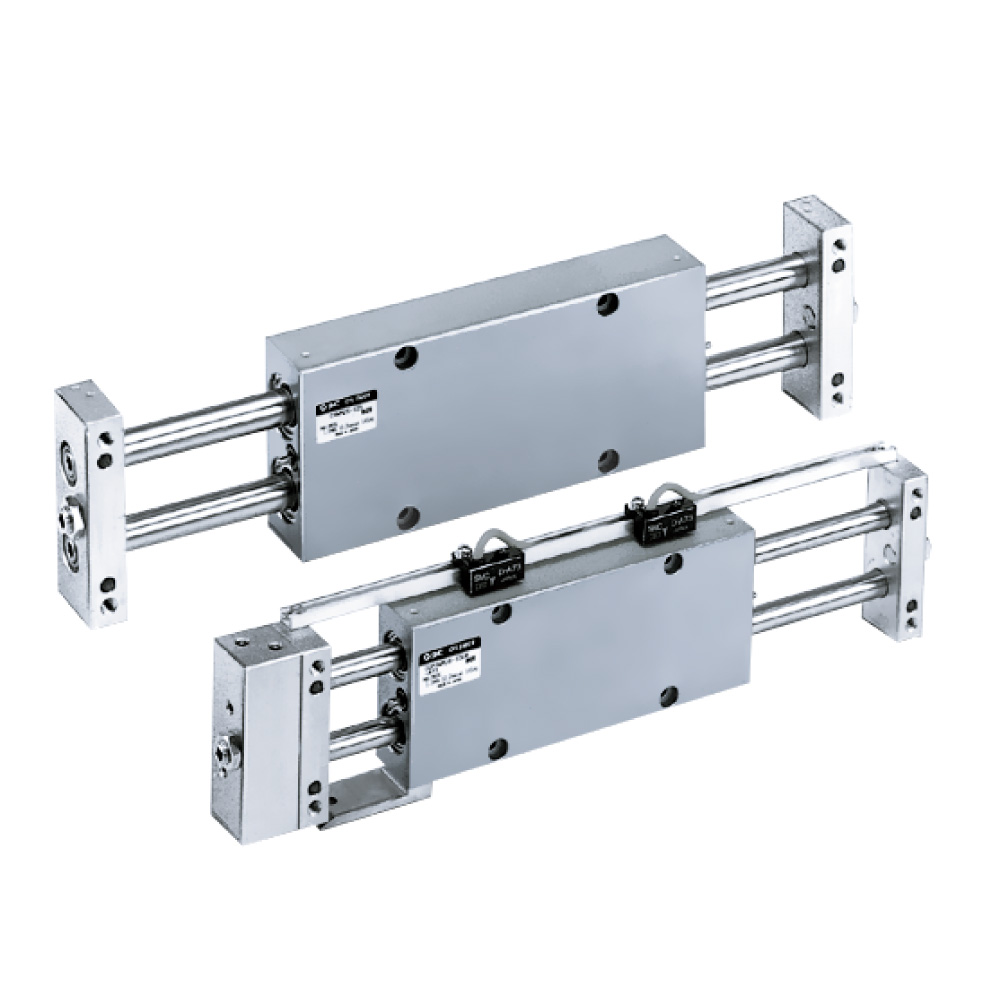

Slide Unit CXW/CDBXW/CDPXW

Air Cylinders » Dual Rod Cylinders

-

・Built-in shock absorber that absorbs impact

・Can be mounted on the housing or on the plate

Highly precise parallelism of cylinders and workpieces

・With auto switch (CDBXW series: CDBXWM, CDBXWL, CDPXW series: CDPXWM, CDPXWL)

Safety Instructions Actuators/Precautions Auto Switches/Precautions

Model Selection/Technical Data Made to Order Common Specifications

Green Procurement (RoHS)

Model Selection/Technical Data Made to Order Common Specifications

Green Procurement (RoHS)

| Type | Bearing | Series | Action | Bore size (mm) |

|---|---|---|---|---|

| Standard | Slide bearing | CXWM | Double acting | 10,16,20,25,32 |

| Standard | Ball bushing bearing | CXWL | Double acting | 10,16,20,25,32 |

Suction Cup/With Non-slip Feature ZP3M

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Pads (Vacuum Suction Cups)-

・An oval flat shape with non-slip feature has been added. [New]

Compatible with workpieces with an elongated adsorption surface

・Longer life (More than twice that of urethane cups)

Cup material: FS61 (Fluoro-based rubber) with excellent abrasion

resistance

Reduced number of cup replacements

・Non-slip special ribs

Diagonal ribs are radially arranged to secure the gripping force in all

directions.

· Prevents workpiece slippage

· Secure adsorbing and transferring are possible.

・Bowl shape with excellent flexibility

Curved workpieces can also be adsorbed.

The cup follows the workpiece shape, making stable adsorption possible.

Horizontal holding force: 387 N (Cup diameter ø100)

Suitable for high-temperature workpieces (200°C)

・Suitable for workpieces with oil film

As oil is ejected to the grooves between special ribs, the lateral slipping

of workpiece can be suppressed even on a steel plate with oil film.

Safety Instructions Vacuum Equipment/Precautions Vacuum Pads/Precautions Series Variations Model Selection Green Procurement (RoHS)

| Series | Cup form | Cup diameter (mm) |

|---|---|---|

| ZP3M-R | Bowl shape | φ32, φ40, φ50, φ63, φ80, φ100 |

| ZP3M-RB | Bowl Bellows Shape | φ32, φ40, φ50, φ63, φ80, φ100 |

| ZP3M-T | Oval flat shape with non-slip feature | 16 x 50, 30 x 90, 40 x 80, 50 x 100 |