There were 162 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Fittings for Special Environments HF1 (Compatible) /HF1B (Compatible)

Equipment for the Food Manufacturing Industry » Fittings and Tubing| Series | Model | Specification |

|---|---|---|

| Stainless Steel 316 One-touch Fittings | KQG2 | HF1B Compatible∗ |

| Stainless Steel 316 Insert Fittings | KFG2 | HF1B Compatible∗ |

| Clean One-touch Fittings | KPQ/KPG | HF1B Compatible∗ |

| S Couplers Stainless Steel Type | KKA | HF1B Compatible∗ |

Magnet Buffer ZP3B□M

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Magnet Buffer-

· Stable buffer reaction force during stroke

· Adsorbs workpieces with different heights, Reduces the impact applied to

a workpiece

· Low particle generation

No particle generation due to the friction of a spring (spring-less

structure)

· Non-rotating

Reduces rotation by 4-pole magnets

· Copper and zinc-free

· Compatible with the secondary battery manufacturing process

| Series | Buffer size | Stroke |

|---|---|---|

| ZP3B1M | M8 x 0.75 | 3 mm,6 mm |

| ZP3B2M | M10 x 1.0 | 3mm,6mm |

| ZP3B3M | M12 x 1.0 | 3 mm,6 mm,16 mm |

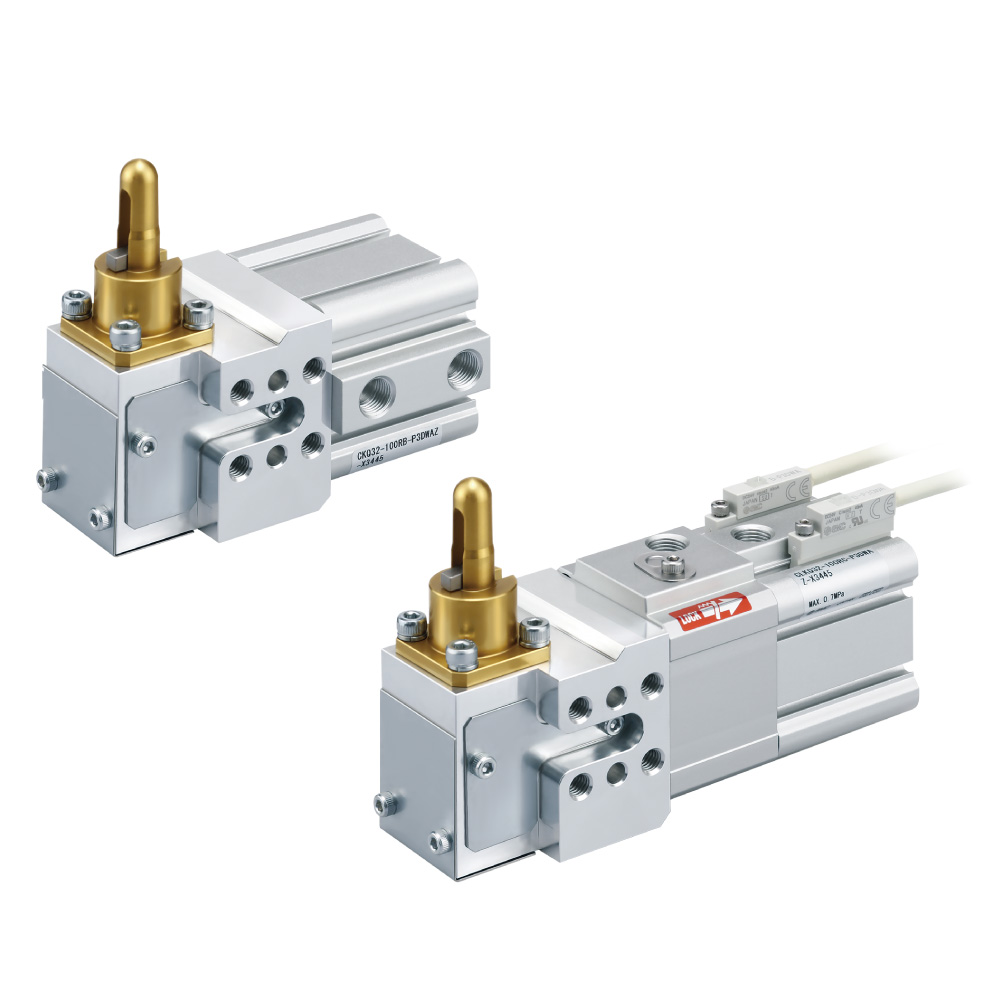

Pin Clamp Cylinder Lateral Compact Type C(L)KQ32-X3445

Air Cylinders » Clamp Cylinders-

・Lateral Compact Type

・Compact: Overall length: 94 mm shorter (183mm→89mm)∗

・Lightweight: Weight: 38% reduction (900g→560g)∗

∗ Compared with the existing product CKQG32-X2081, LOW type, without

lock

・Lock mechanism to prevent the dropping of workpieces during

emergency stops

・Various clamp arm positions and port positions are available.

・Mountable on 2 surfaces

Safety Instructions Actuators/Precautions Auto Switches/Precautions

Model Selection/Technical Data Green Procurement (RoHS)

Model Selection/Technical Data Green Procurement (RoHS)

| Type | Series | Guide pin shape | Bore size(mm) |

|---|---|---|---|

| Lateral Compact Type Without lock | CKQ32-X3445 | Round type Diamond type | 32 |

| Lateral Compact Type With lock | CLKQ32-X3445 | Round type Diamond type | 32 |

Vacuum Gripper System (Foam Type) ZGS

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: IO-Link Compatible ProductsGrippers for Collaborative Robots » Vacuum Grippers (Ejector Type)

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Gripper System (Foam Type)

IO-Link Devices » Vacuum Gripper System

-

・Foam size: 300 mm x 180 mm / 200 mm x 120 mm [New]

・Suitable for the palletizing and depalletizing of corrugated cardboard,

etc.

・Ejector unit

Combines all functions required for adsorption

(Ejector, Supply valve/Release valve, Silencer, Pressure switch)

・Can be used immediately by simply connecting 1 electrical cable and air

piping

・Compatible with the collaborative robots of 4 companies

UNIVERSAL ROBOTS, OMRON/TECHMAN ROBOT, FANUC,

YASKAWA Electric

・Lifting force

440 N (200 x 120) (At −63 kPa)

880 N (300 x 180) (At −63 kPa)

2144 N (400 x 240) (At −75 kPa)

・IO-Link compatible∗

∗ Only for sizes 300 x 180 and 200 x 120

▶IO-Link Devices

| Series | Cup form | Foam specifications Size | Theoretical lifting force [N] | Foam specifications Thickness |

|---|---|---|---|---|

| ZGS | Foam | 400 mm × 240 mm 300 mm × 180 mm 200 mm × 120 mm | 2144 [-75k Pa] 880 [-63 kPa] 440 [-63 kPa] | 20mm 30mm |

Multi Hand Adapter RMMA

Air Gripper for Collaborative Robots » Air GrippersAir Gripper for Collaborative Robots » Multi Hand Adapter

-

・Allows for the handling of various workpieces by a single robot

・Allows for the simultaneous transfer of multiple workpieces

・Up to 3 grippers can be mounted.

・Reduces tool changing time

・Robot arm end standards: Equivalent to ISO9409-1-50-4-M6

・3 gripper mounting angles

| Series | Mounting angle | Max. work load (kg) |

|---|---|---|

| RMMA | 90°,120°,180° | 20 |

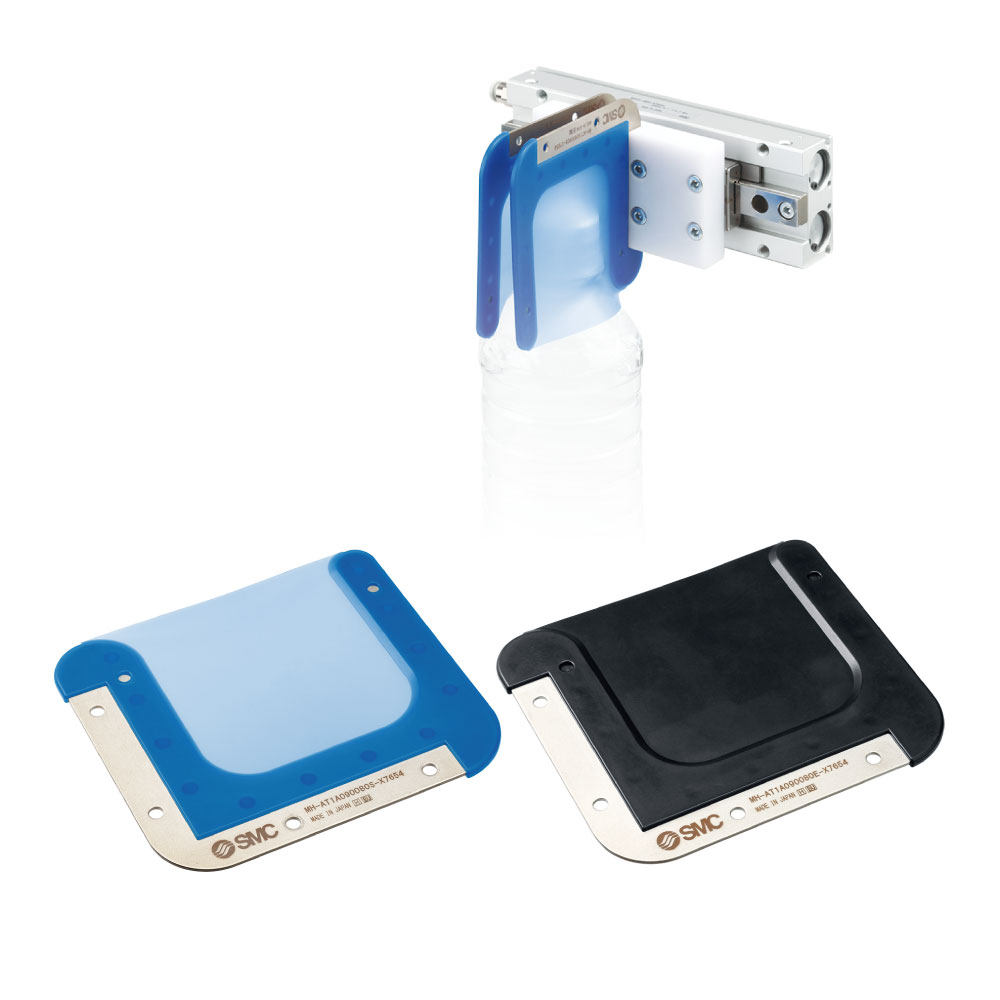

Elastic Finger MH-X7654

Air Gripper for Collaborative Robots » Elastic FingerRotary Actuators/Air Grippers » Elastic Finger

-

・Rubber sheet fingers enable gripping of an indefinite workpiece

・Design of the finger according to the workpiece shape is not required.

・Allows for gripping of tightly packed workpieces

The elastic finger mounting attachment to be produced by the customer.

・Material

・Silicone rubber (Blue)

This product is made of materials compliant with FDA (U.S. Food and

Drug Administration) regulations as well as Japan Food Sanitation Act

standards.

・EPDM (Black)

| Series | Material | Color |

|---|---|---|

| MH-AT1A090080E-X7654 | Ethylene propylene rubber (EPDM) | Black |

| MH-AT1A090080S-X7654 | Silicone rubber (Si) | Blue |

Electric Vacuum Gripper for Collaborative Robots ZXPE5

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Gripper for Collaborative RobotsElectric Actuators/Cylinders » Grippers for Collaborative Robots

Grippers for Collaborative Robots » Electric Vacuum Grippers (Built-in Vacuum Pump Type)

-

・A vacuum gripper that doesn't require an air source

・Operation possible by simply connecting an electrical wire connector

Can be used without an air source due to the built-in vacuum pump

・Unitization of the peripheral devices required for adsorption

The vacuum pump, atmospheric release valve, pressure monitor,

and cups have been integrated.

・Current consumption: Max. 64% reduction

Energy-saving operation possible via automatic/manual modes

・Lightweight: 556 g

・A wide variety of cup variations are available to support a wide range of

workpiece shapes.

・Standards: Conforming to ISO9409-1-50-4-M6

∗1 These are the values under SMC measurement conditions when the gripper is in continuous mode (the vacuum pump working continuously) and may vary depending on the

atmospheric pressure (weather, altitude, etc.) and the measurement method.

∗2 May be restricted depending on the cup diameter, mounting orientation, or workpiece. Please use within the max. work load. Suction and transfer exceeding the max. work load may result in product failure and the dropping of workpieces.

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Cup form | Cup diameter | Max. suction flow rate*1 [L/min(ANR)] | Max. work load*2

[Kg] |

|---|---|---|---|---|

| ZXPE5 | Flat Flat with rib Bellows Thin flat Multistage bellows 2.5-stage bellows 5.5-stage bellows Flat type for film packaging workpieces | φ8 to φ32 | 4.5 | 5 |

Analog Auto Switch and Display Sensor Monitor D-MH1□

Rotary Actuators/Air Grippers » Auto SwitchesSwitches/Sensors/Controller » Auto Switches for Rotary Actuators and Air Grippers

-

・Outputs the analog voltage according to the actuator stroke position

・A single switch can discriminate between max. 3 position points.

Repeatability: ±20 mV (Converted stroke ±0.1 mm)

Discriminable dimensional difference: 0.2 mm

∗ The value is in the high-resolution range. The converted stroke value

varies depending on the actuator.

∗ For air grippers, this is the value for one side of the finger. When it is

converted to the dimension of the workpiece to be gripped, the value is

doubled.

・Detection position display and setting away from the actuator are

possible.

・Analog voltage output (1 to 5 V)

・Can also be used with the analog auto switch single unit

・Reduced setting labor

・No need to fine-tune the switch mounting position

・Easy adjustment even in narrow places and on moving parts

・Improved productivity

· Gripper fully open R gripping R gripping failure detection

· Minimized lead wire disconnection risk

· Preventive maintenance

· Display of gripper finger wear

· Visualization of daily inspections (Origin position/ Gripping position)

| Series | Type | Description |

|---|---|---|

| D-MH1AD(V) | Analog auto switch | Analog output sensor (1 to 5 V) |

| D-MH1BN | Sensor monitor | Display sensor monitor, NPN 2 outputs |

| D-MH1BP | Sensor monitor | Display sensor monitor, PNP 2 outputs |

Compact Compressor CRP

Compact Compressor » Compact Compressor-

・Supplies compressed air in an environment with no air source such as

cobots, AGV and AMRs

・Compact: 154 mm (Width) x 134 mm (Height) x 100 mm (Depth)

・Lightweight: 3.5 kg (Compressor: 3.1 kg, Controller: 0.4 kg)

A single unit can be used to provide positive or vacuum pressure

(vacuum pump).

Max. discharge pressure: 0.55 MPa

Ultimate vacuum pressure: −70 kPa

・Oil-free

・Noise: 55 dB or less (When the silencer ANB1-01 is installed) (When

supplying positive pressure)

| Series | Compression method | Max. discharge pressure Ultimate vacuum pressure | Max. discharge flow rate Max. suction flow rate |

|---|---|---|---|

| CRP | Reciprocating (Oil-free) | 0.55 MPa −70 kPa | 10 L/min (ANR) |

Separate Controller Ionizer / Slim Bar Type IZT44/45

Static Neutralization Equipment » Static Neutralization Equipment Ionizer Bar Type-

・Powerfully eliminates static electricity from highly charged workpieces

Pulse AC type, High density emitter arrangement (6 times the number of emitters∗)

* Compared to the existing model

・Can be mounted in a narrow space (Height 23 mm x Width 20 mm)

Can be installed through gaps between equipment

Improved installation, replacement, and maintenance in narrow spaces

・Powerful static elimination is possible without air supply.

・High speed static elimination: Discharge time reduced by approx. 60%

・2-way directional static elimination using branch cables

2 ionizer bars can be connected to one high voltage power supply.

・Up to 4 high voltage power supply modules can be connected to one controller. (IZT45)

・Flexible layout possible with various module connection methods (IZT45)

Controller to Bar maximum installation distance: 15 m

Variations/Application Examples Antistatic Equipment Glossary

Safety Instructions Green Procurement (RoHS)

Safety Instructions Green Procurement (RoHS)

| Series | Type | Ion generation method | Function |

|---|---|---|---|

| IZT44 Slim bar type | Separate controller | Corona discharge type | High voltage error detection Output check |

| IZT45 Slim bar type | Separate controller | Corona discharge type | Auto balance Maintenance detection High voltage error detection Ion generation stop signal Output check |