There were 374 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Longer Life Cylinder MGJ-XB24

Air Cylinders » Guide Cylinders-

・New technology offers at least 4 times better durability.

・Employs the same specification and mounting dimensions as

the existing models, MGJ Miniature Guide Rod Cylinder series

Safety Instructions Actuators/Precautions

Auto Switches/Precautions Model Selection/Technical Data

Green Procurement (RoHS)

Auto Switches/Precautions Model Selection/Technical Data

Green Procurement (RoHS)

| Type | Series | Action | Bore size (mm) |

|---|---|---|---|

| Longer Life | MGJ-XB24 | Double acting | 6,10 |

3-Screen Display High-Precision Digital Pressure Switch ISE20B

Arc Welding Process Equipment » Detection Switches

-

・Setting is possible while checking the measured value.

・Allows pressure control and value management of shielding gas.

・Compatible with Argon (Ar), Carbon Dioxide

(CO2) and the Mixed Gas (Ar+CO2)

Safety Instructions Pressure Switches/Flow Switches/Precautions

Pressure Switch Series Variations/Application Example Glossary of Terms/Technical Information

Green Procurement (RoHS)

Pressure Switch Series Variations/Application Example Glossary of Terms/Technical Information

Green Procurement (RoHS)

| Series | Output type | Type | Rated pressure range | Enclosure | Applicable fluid |

|---|---|---|---|---|---|

| ISE20B | 2 outputs Analog output (Voltage/Current) Switch: 1 output | Positive pressure | −0.100~1.000MPa | IP65 | Air |

JIS Standard Compact Hydraulic Cylinder CHK□/CHDK□

Hydraulic Equipment » Hydraulic Cylinders

-

・Lightweight, compact aluminum body

・It is possible to mount auto switches.

・Same longitudinal dimensions for cylinders with/without auto switches

・Compliant with JIS Standards (CHKD series)

・With auto switch (CHDK□ series: CHDKD, CHDKG)

Safety Instructions Hydraulic Cylinders/Precautions Auto Switches/Precautions

Series Variations Technical Data Green Procurement (RoHS)

Series Variations Technical Data Green Procurement (RoHS)

| Series | Nominal pressure (MPa) | Body material | Action | Bore Size (mm) |

|---|---|---|---|---|

| CHKD | 10 | Aluminum | Double acting, Single rod | 20, 25, 32, 40, 50 63, 80, 100 |

| CHKG | 16 | Aluminum | Double acting, Single rod | 20, 25, 32, 40, 50 63, 80, 100 |

Peltier-Type Thermo-con HEC

Temperature Control Equipment » Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

-

・For applications requiring high-precision temperature control

・High-precision, refrigerant-free temperature control equipment that uses a Peltier

device

・Simple structure and high reliability

・Can easily be built into equipment due to its compact and low-vibration design

・Compatible with a wide range of power supply voltages

・Compliant with UL Standards, CE-marking

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HEC | 10 to 60℃ | 230 W, 600 W | ±0.01 to 0.03℃ | Peltier-type air-cooled | Tap water |

| HEC | 10 to 60℃ | 140 W, 320 W | ±0.01 to 0.03℃ | Peltier-type water-cooled | Tap water, Ethylene glycol aqueous solution (20%) |

| HEC | 10 to 60℃ | 600 W, 1200 W | ±0.01 to 0.03℃ | Peltier-type water-cooled | Tap water, Fluorinated fluid |

Water-cooled Thermo-chiller/High-performance Type HRW

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: DeviceNet Compatible ProductsTemperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance Type & Inverter Type

-

・Direct heat exchanger for in-plant circulating fluid

・Can control the temperature over a wide range since a compressor is not required.

・Suitable for semiconductor processing equipment with a wide variety of features, such as high-temperature stability, a wide temperature range, failure diagnosis, external communication, etc.

・Compliant with UL Standards, SEMI Standards, CE-marking

・It is possible to select the inverter type.

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRW | 20 to 90℃ | 2 kW, 8 kW, 15 kW, 30 kW | ±0.3℃ | Water-cooled type (Without compressor) | Fluorinated, Tap water, Deionized water, Ethylene glycol aqueous solution (60%) |

Thermo-chiller Compact Dual/Basic Type for Lasers HRLE

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Dual Channel Thermo chiller for Lasers-

・The temperatures of 2 fluid channel systems can be controlled individually by 1 chiller.

・Space saving, Reduced wiring

Footprint reduced by 21%

One power supply system for 2 channels

・Energy saving

Power consumption reduced by 17%

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity (CH1, 2 total) | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRLE050-A | CH1:15 to 25℃ CH2:CH1 temperature + 0 to 15℃ | 4.8kW/5.8k (50Hz/60Hz) | CH1:±0.1 CH2:±0.5 | Air-cooled refrigeration | Tap water, Deionized (pure) water |

| HRLE050-W | CH1:15 to 25℃ CH2:CH1 temperature + 0 to 15℃ | 4.8kW/5.8k (50Hz/60Hz) | CH1:±0.1 CH2:±0.5 | Water-cooled refrigeration | Tap water, Deionized (pure) water |

| HRLE090-A | CH1:15 to 25℃ CH2:CH1 temperature + 0 to 15℃ | 8.0 kW/9.5 kW (50 Hz/60 Hz) | CH1: ±0.1 CH2: ±0.5 | Air-cooled refrigeration | Tap water, Deionized (pure) water |

| HRLE090-W | CH1: 9 kw,19 kW, 26 kW CH2: 1.0 kW (Max. 1.5 kW) | 9.5 kW/11.0 kW (50 Hz/60 Hz) | CH1: ±0.1 CH2: ±0.5 | Water-cooled refrigeration | Tap water, Deionized (pure) water |

Thermo-chiller/Inverter Type HRSH

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

-

・Complete with energy-saving triple inverter!

・Outdoor installation, Splashproof type (IPX4)

・Max. ambient temperature: 45℃

・Min. ambient temperature: –20℃ (For the air-cooled type)

・Temperature stability: ±0.1℃ (When a load is stable)

・Space saving and lightweight: 280 kg (25 kW type)

・Compliant with UL Standards, CE-marking

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRSH | 5 to 35℃ | 10 kW 15 kW 20 kW 25 kW 28 kW | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water Deionized water Ethylene glycol aqueous solution (15%) |

High Pressure Coolant Valve SGH

Process Valves » Coolant Valves-

・Max. operating pressure: 3 MPa, 7 MPa, 10 MPa [New], 14 MPa [New]

・Applicable to high-speed grinding and long drilling processes

・Coolant valve for high-pressure coolant liquid that is ideal for lubrication, dust blowing, and cooling

・Service life: 3 million cycles (Based on SMC's test conditions)

・Water hammer: Reduced by 20% (Compared to existing model, VNH series)

・Power consumption: 0.35 W (24 VDC, V116)

・The 3-port dual pressure type has been standardized.

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics Series Variations/Process, Coolant Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics Series Variations/Process, Coolant Valves List

Green Procurement (RoHS)

| Series | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|

| SGH | N.C./N.O. | 3/8 to 1 | 7.5 to 15.9 |

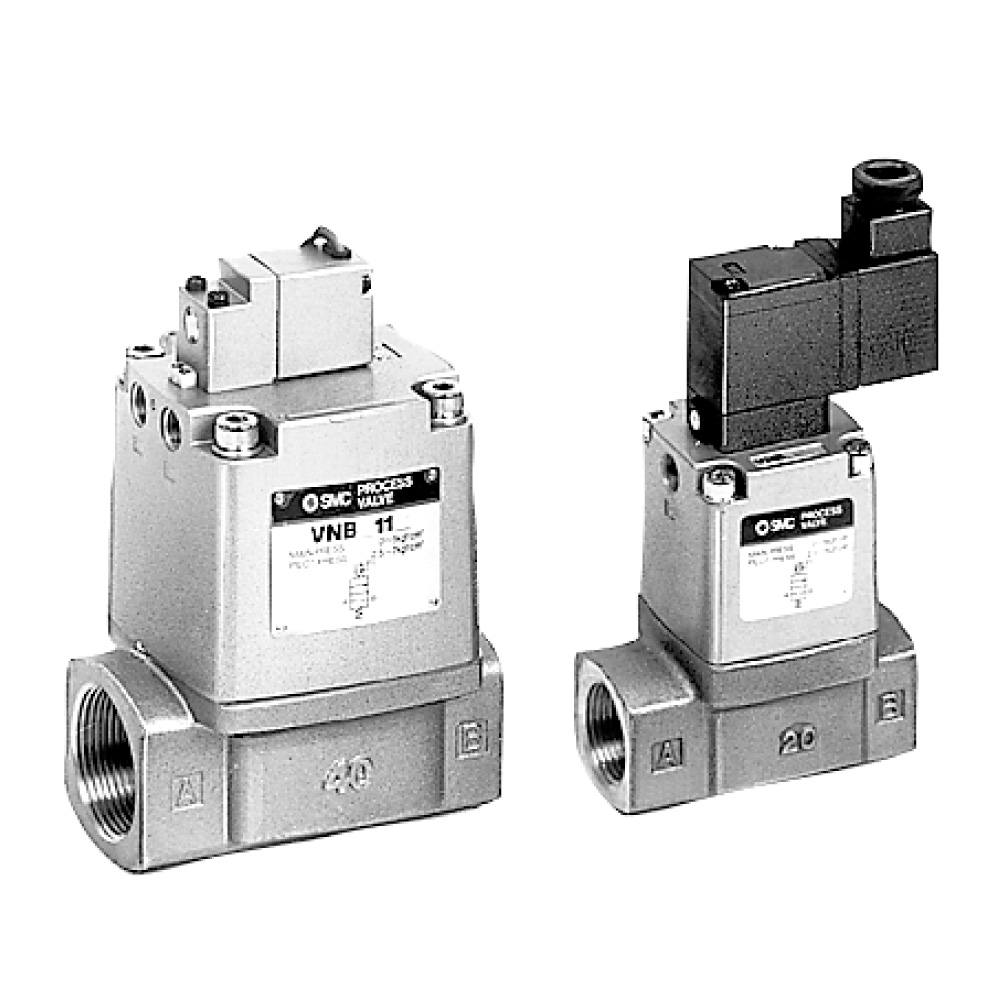

Process Valve/2 Port Valve (2 Way Valve) for Fluid Control VNB

Process Valves » 2/3 Port Valves for General Purpose Fluid Control

-

・For controlling various fluids

・Can operate with a wide range of fluids, such as air, water, oil, gas, vacuum, etc., depending on the selected body and seal materials

・Air operated, external pilot solenoid

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics Series Variations/Process, Coolant Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics Series Variations/Process, Coolant Valves List

Green Procurement (RoHS)

| Series | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|

| VNB | N.C./N.O./C.O. | 1/8 to 2 1 1/4B to 2B | 7 to 50 |

Direct Operated 2 Port Solenoid Valve (2 Way Valve) VX2

Process Valves » 2/3 Port Solenoid Valves/Air Operated Valves-

・For air, medium vacuum, water, oil, steam (Can be used with heated water)

・Flow rate: 20% more flow*

・Height: 10% smaller*

・Weight: 30% lighter*

・Body materials: Aluminum, Resin, C37, Stainless steel

・Available with One-touch fittings (Resin body)

*Comparison made with SMC’s existing model

・Manifold type no.: VVX21, VVX22, VVX23

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics

Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics

Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List

Green Procurement (RoHS)

| Series | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|

| VX21/22/23 | N.C./N.O. | 1/8 to 1/2 ø6 to ø12 | 2 to 10 |