There were 228 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Line Filter AFF

Mist Separator AM

Micro Mist Separator AMD

Micro Mist Separator with Pre-filter AMH

Activated Carbon Filter AMK

Air Preparation Equipment » Air Preparation Filters-

・Modular connection type

・Compressed air purity class: ISO 8573

・Face-to-face and depth dimensions reduced by 30%

・Weight reduced by 50%

AFF/AM□20: 0.19 kg (Existing model: 0.38 kg)

・Flow capacity increased by 50%

・No tools are required.

Easy replacement of the element

・Transparent bowl guard (2-layer construction)

・Color-identifiable elements

・With element service indicator

・With clogging switch/With element service indicator

Safety Instructions Air Preparation Equipment/Precautions Selection/Technical Data Green Procurement (RoHS) Element Part No.

| Type | Series | Filtration (μm) | Oil mist concentration on the outlet side | Air flow (L/min[ANR]) | Port size |

|---|---|---|---|---|---|

| Line filter | AFF | 1.0 (Filtration efficiency: 99%) | - | 300 to 3700 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

| Mist separator | AM | 0.1 (Filtration efficiency: 99%) | 1 (≈ 0.8 ppm) or less | 300 to 3700 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

| Micro mist separator | AMD | 0.01 (Filtration efficiency: 99.9%) | 0.1 (≈ 0.08 ppm) or less | 300 to 3700 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

| Micro Mist Separator with Pre-filter | AMH | 0.01 (Filtration efficiency: 99.9%) | 0.1 (≈ 0.08 ppm) or less | 750 to 1500 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

| Activated carbon filter | AMK | - | 0.003 (≈ 0.0025 ppm) or less | 300 to 3700 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

Air Cooled Aftercooler HAA

Air Preparation Equipment » Aftercoolers/Air Tanks

-

・Can cool high-temperature compressed air from compressors down to

40°C or less and efficiently remove moisture from the air

・Cooling equipment is not required for this air-cooled type.

・Easy maintenance and reasonable running costs,

No need to worry about freezing or running out of water supply.

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Series | Applicable compressor (kW) | Air flow capacity L/min (ANR) |

|---|---|---|

| HAA | 7.5 to 37 | 1000 to 5700 |

Basic Vacuum Pad (Vacuum Suction Cup) ZP

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Pads (Vacuum Suction Cups)

-

・12 sizes, 6 types of pad forms

The mounting bracket can be selected according to the application.

・Pad form: Flat type, Flat type with ribs, Bellows type,

Thin flat type, Thin flat type with ribs, Deep type

・Mounting: Male thread, Female thread

・Vacuum inlet direction: Vertical, Lateral

・Vacuum inlet: Male thread, Female thread, One-touch fitting, Barb fitting

・Buffer: Without, With

[Buffer stroke [mm]: 6, 10, 15, 20, 25, 30, 40, 50]

Safety Instructions Vacuum Equipment/Precautions Vacuum Pads/Precautions Series Variations Model Selection Mounting Bracket Assembly (p.121-130) Green Procurement (RoHS)

| Series | Pad form | Pad diameter(mm) |

|---|---|---|

| ZP | Flat type | φ2,φ4,φ6,φ8,φ10,φ13,φ16, φ20,φ25,φ32,φ40,φ50 |

| ZP | Flat type with ribs | φ10,φ13,φ16,φ20,φ25,φ32,φ40,φ50 |

| ZP | Flat type (Ball joint) | φ10,φ13,φ16,φ20,φ25,φ32,φ40,φ50 |

| ZP | Bellows type | φ6,φ8,φ10,φ13,φ16, φ20,φ25,φ32,φ40,φ50 |

| ZP | Thin flat type | φ10,φ13,φ16 |

| ZP | Thin flat type with ribs | φ10,φ13,φ16 |

| ZP | Deep type | φ10, φ16, φ25, φ40 |

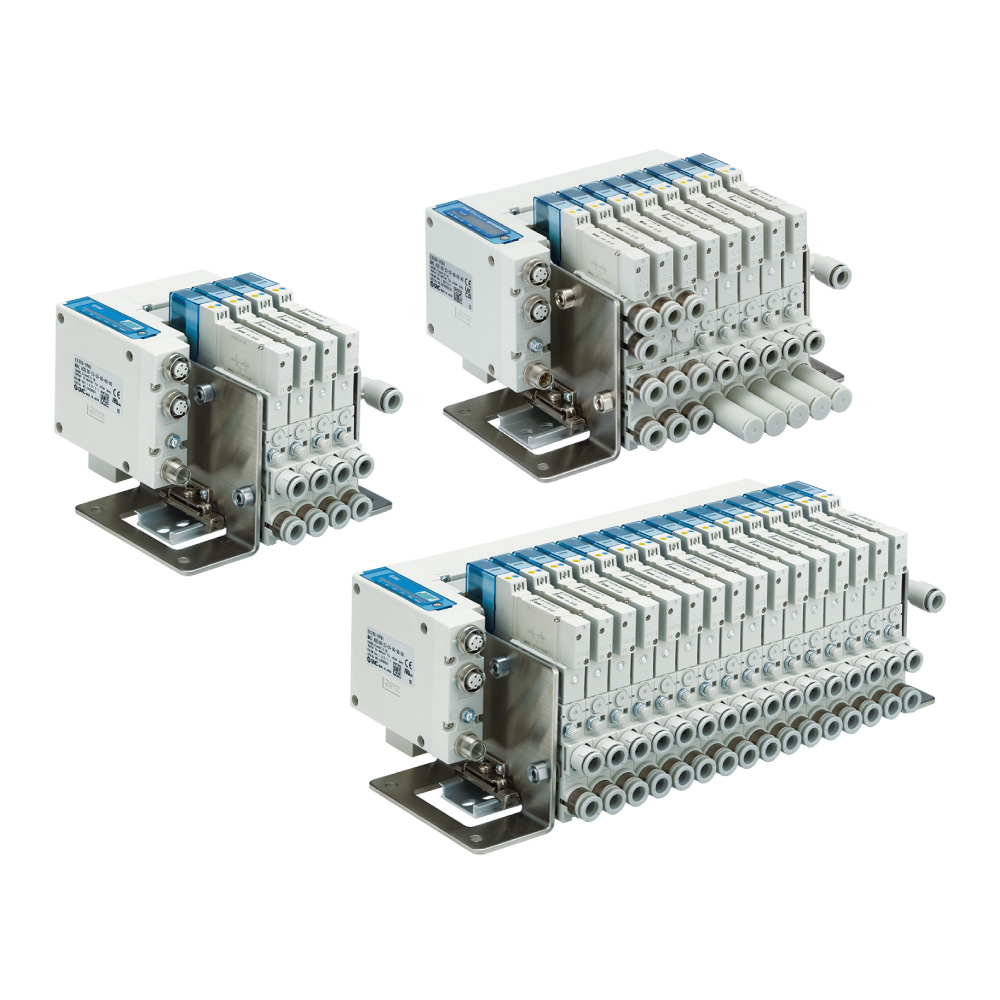

Vacuum Manifold for Fieldbus System ZKJ

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump SystemsIndustrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: PROFINET Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherNet/IP Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: IO-Link Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherCAT Compatible Products

IO-Link Devices » Vacuum Unit/Vacuum Manifold

-

・Vacuum pads and actuator driving can be controlled with a single

manifold [New]

・Positive pressure unit [New]

5-port solenoid valve

・Vacuum unit

Energy saving ejector Air consumption: 92% reduction

・Fieldbus compatible

Space saving: Requires no separate input/output units

Reduced wiring time

Compatible protocols: PROFINET, IO-Link, EtherNet/IP, EtherCAT

・Exhaust sealing function

Quick workpiece release

・4 stations/8 stations/12 stations/16 stations manifold compatible

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|

| ZKJ07 | 0.7 | 31 | 26 |

| ZKJ10 | 1.0 | 53 | 48 |

| ZKJ12 | 1.2 | 63 | 68 |

| ZKJ15 | 1.5 | 74 | 102 |

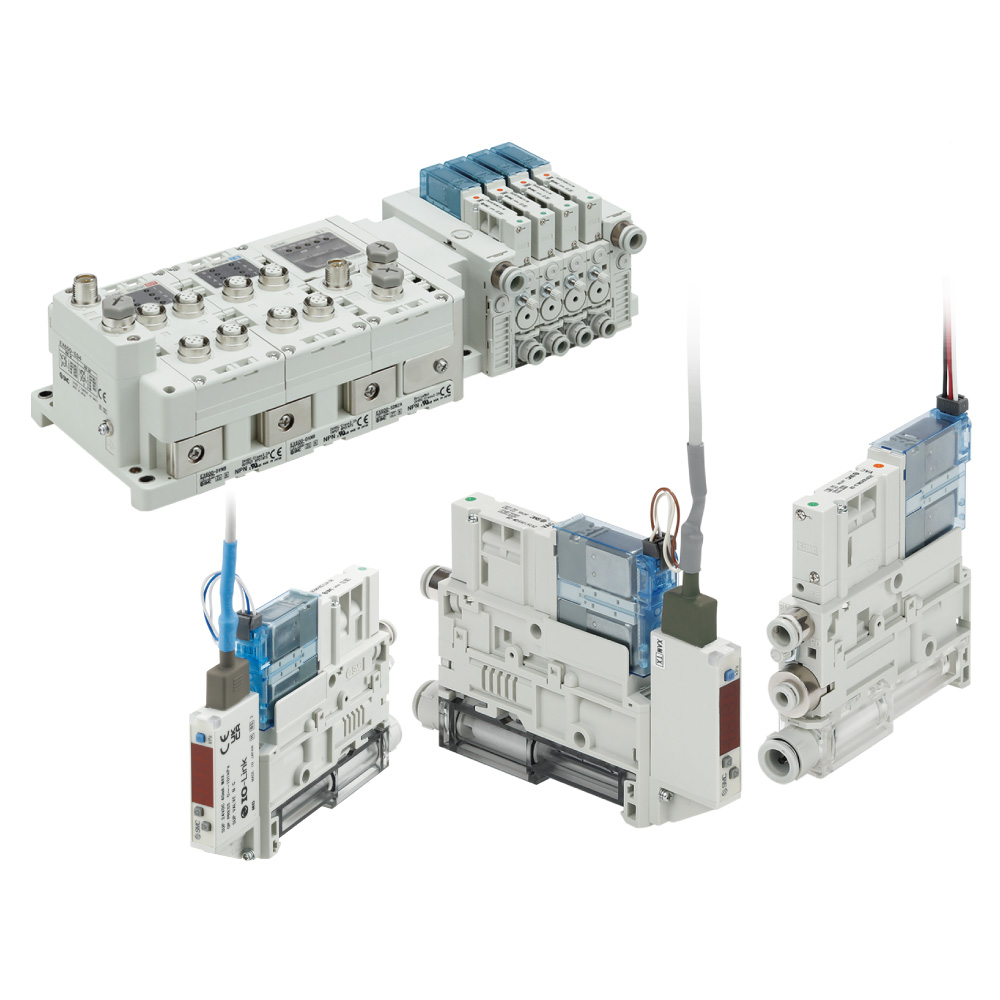

Vacuum Unit (Vacuum Generators) ZK2□A

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems-

・Supply valve: An N.O. specification has been added.

Can hold vacuum∗ even when the power goes out or is turned off

Prevents the sudden dropping of workpieces∗

∗ Supposing the supply pressure is being maintained

・An IO-Link compatible pressure switch has been added.

Allows for ejector control with a single communication line

Reading of the device information and parameter batch settings are

possible.

・Compatible with ejector systems and vacuum pump systems

・Energy saving ejector

Air supply is cut-off when vacuum is reached.

Air consumption: 93% reduction (Under SMC’s measurement conditions)

・More efficient ejector: Suction flow increased by 50% (Compared to other

SMC 1-stage ejectors)

・Energy saving efficiency: 93% reduction

・Improved low noise and suction flow by adoption of a high-noise

reduction silencer

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZK2□07 | 0.7 | 29 | 24 | 2 to 40 | ZK2□00 |

| ZK2□10 | 1.0 | 44 | 40 | 2 to 50 | ZK2□00 |

| ZK2□12 | 1.2 | 61 | 58 | 2 to 125 | ZK2□00 |

| ZK2□15 | 1.5 | 67 | 90 | 2 to 150 | ZK2□00 |

Step Data Input Type Controller JXC51/61

Electric Actuators/Cylinders » Controllers/Drivers

-

・The controller is already set with the data of the actuator.

(The actuator and controller are provided as a set.)

・Easy operation and simple setting: Easy mode, Detail setting: Normal mode

・Teaching box, controller setting software

Safety Instructions Electric Actuators/Precautions Features

Series Variations Simplified Selection Flow Chart Wiring Method Green Procurement (RoHS) CE/UL-compliance List

Series Variations Simplified Selection Flow Chart Wiring Method Green Procurement (RoHS) CE/UL-compliance List

| Type | Series | Compatible motor | Power supply voltage | Parallel I/O Input | Parallel I/O Output | Number of step data |

|---|---|---|---|---|---|---|

| Step data input type | JXC51/61 | Step motor (Servo/24 VDC) | 24 VDC ±10% | 11 (Photo-coupler isolation) | 13 (Photo-coupler isolation) | 64 points |

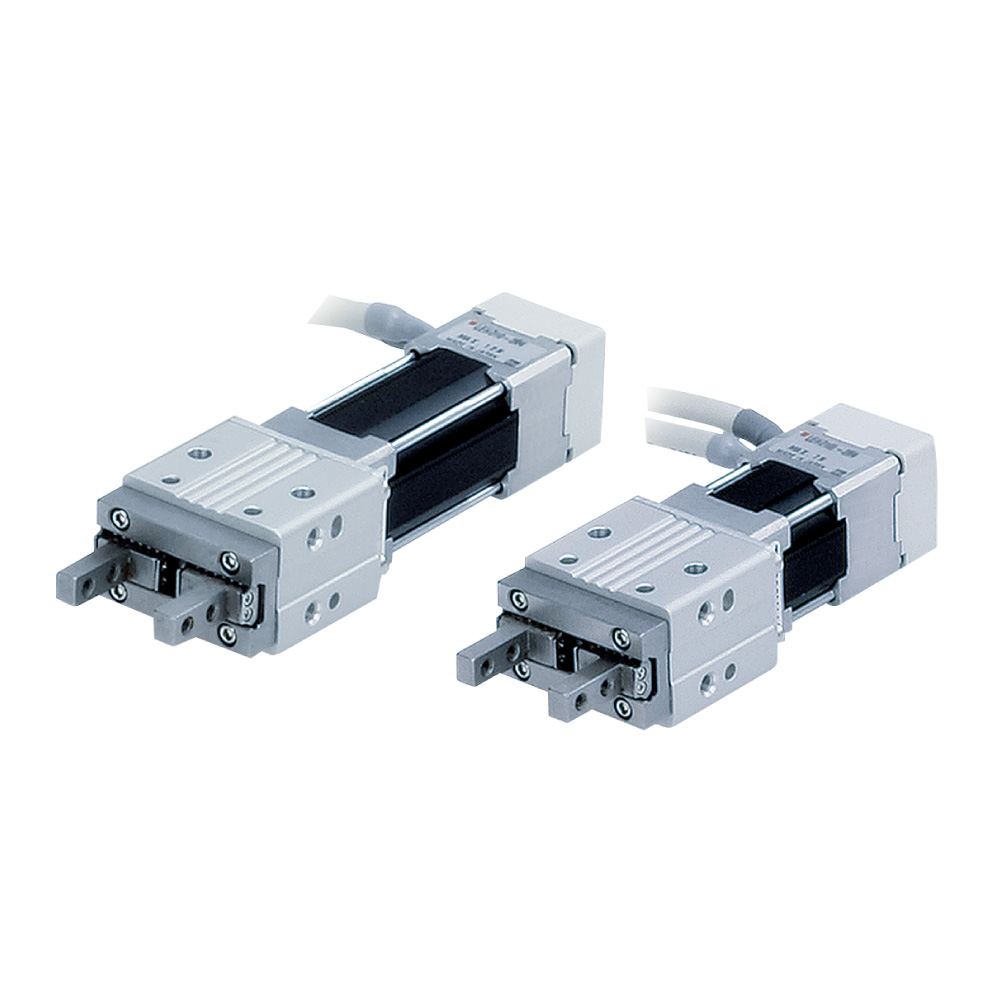

Electric Gripper 2-Finger Type (Z Type) LEHZ

Electric Actuators/Cylinders » Grippers

-

・Easy setting: Data can be set with only 2 items, position and force.

The controller is already set with the data of the actuator.

(The actuator and controller are provided as a set.)

・Equipped with a drop prevention function

(All series come equipped with a self-lock mechanism.)

・The self-lock mechanism reduces power consumption.

・Equipped with a gripping check function

・It is possible to set the position, speed, and force. (64 points)

Safety Instructions Electric Actuators/Precautions Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS) CE/UL-compliance List Actuator Cable I/O Cable

| Series | Body size | Open and close stroke/ both sides (mm) | Gripping force [N] Basic | Gripping force [N] Compact | Opening and closing speed (mm/s) |

|---|---|---|---|---|---|

| LEHZ | 10 | 4 | 6 to 14 | 2 to 6 | 5 to 80 |

| LEHZ | 16 | 6 | 6 to 14 | 3 to 8 | 5 to 80 |

| LEHZ | 20 | 10 | 16 to 40 | 11 to 28 | 5 to 100 |

| LEHZ | 25 | 14 | 16 to 40 | 11 to 28 | 5 to 100 |

| LEHZ | 32 | 22 | 52 to 130 | ― | 5 to 120 |

| LEHZ | 40 | 30 | 84 to 210 | ― | 5 to 120 |

Electric Rotary Table LER

Electric Actuators/Cylinders » Rotary Tables

-

・Rotation angle: 360º , 320º (310º), 180º , 90º

( ) The value indicated in brackets shows the value for the LER10.

・Low profile: Height 42 mm (LER10)

・Space saving: Built-in step motor

・Shock-less/high speed actuation

Max. speed: 420°/sec (7.33 rad/sec)

Max. acceleration/deceleration: 3000º/sec2 (52.36 rad/sec2)

・It is possible to set the speed, acceleration/deceleration, and position.

Max. 64 points

・Energy saving: Automatic 40% power reduction after the table has stopped

・Easy setting: Data can be set with only 2 items, position and speed.

The controller is already set with the data of the actuator. (The actuator and controller are provided as a set.)

*Value when an external stopper is mounted

Safety Instructions Electric Actuators/Precautions Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS) CE/UL-compliance List Actuator Cable I/O Cable

| Model | Rotating torque [N·m] Basic | Rotating torque [N·m] High torque | Max. speed [º/s] Basic | Max. speed [º/s] High torque | Positioning repeatability [º] Basic | Positioning repeatability [º] High torque |

|---|---|---|---|---|---|---|

| LER10 | 0.22 | 0.32 | 420 | 280 | ±0.05 (At the end: ±0.01)* | ±0.05 (At the end: ±0.01)* |

| LER30 | 0.8 | 1.2 | 420 | 280 | ±0.05 (At the end: ±0.01)* | ±0.05 (At the end: ±0.01)* |

| LER50 | 6.6 | 10 | 420 | 280 | ±0.05 (At the end: ±0.01)* | ±0.05 (At the end: ±0.01)* |

Card Motor LAT3

Electric Actuators/Cylinders » Card Motor

-

・The transportation, pushing, and length measurement systems have beenminiaturized through the use of a linear motor.

・Thickness 9 mm, Weight 130 g (At a stroke of 10 mm)

・Linear motor type: Moving magnet type linear motor

・Max. pushing force: 6 N

・Positioning repeatability: ±5 μm

・Pushing measurement accuracy: ±10 μm

・Max. operating frequency: 500 cpm

Safety Instructions Electric Actuators/Precautions Features

Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

| Model | Stroke (mm) | Sensor (Optical linear encoder) Resolution | Pushing Maximum Instantaneous thrust | Positioning repeatability | Pushing measurement accuracy | Maximum speed |

|---|---|---|---|---|---|---|

| LAT3F | 10, 20, 30, 50 | 1.25μm | Up to 6 N | ±5μm | ±10μm | 400 mm/s |

| LAT3M | 50 | 5μm | Up to 6 N | ±20μm | ±40μm | 400 mm/s |

| LAT3 | 10, 20, 30 | 30μm | Up to 6 N | ±90μm | ±100μm | 400 mm/s |

Air Gripper Unit for Collaborative Robots JMHZ2-X7400B-CRX

for the FANUC CORPORATION CRX Series

Rotary Actuators/Air Grippers » Air Gripper Unit for Collaborative Robots-

・Plug and Play configuration for immediate use

・FANUC CRX plug-in software: Easy programming

・Compact, lightweight product with high gripping force due to air operation

・High rigidity and high precision due to its guide-integrated construction

Repeatability: ±0.01 mm due to the adoption of a high-precision linear guide

Higher rigidity due to the adoption of a linear guide of the higher rigidity and precision

・Operate by simply connecting 1 air supply tube and an electrical wiring M8 connector.

・Integrated solenoid valve, speed adjustment mechanism, and auto switch

・A split protective cover for easy air gripper maintenance

・Standards: ISO 9409-1-50-4-M6

| Type | Series | Cylinder bore size (mm) |

|---|---|---|

| For Collaborative Robots | JMHZ2-16D-X7400B-CRX | 16 |