There were 228 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

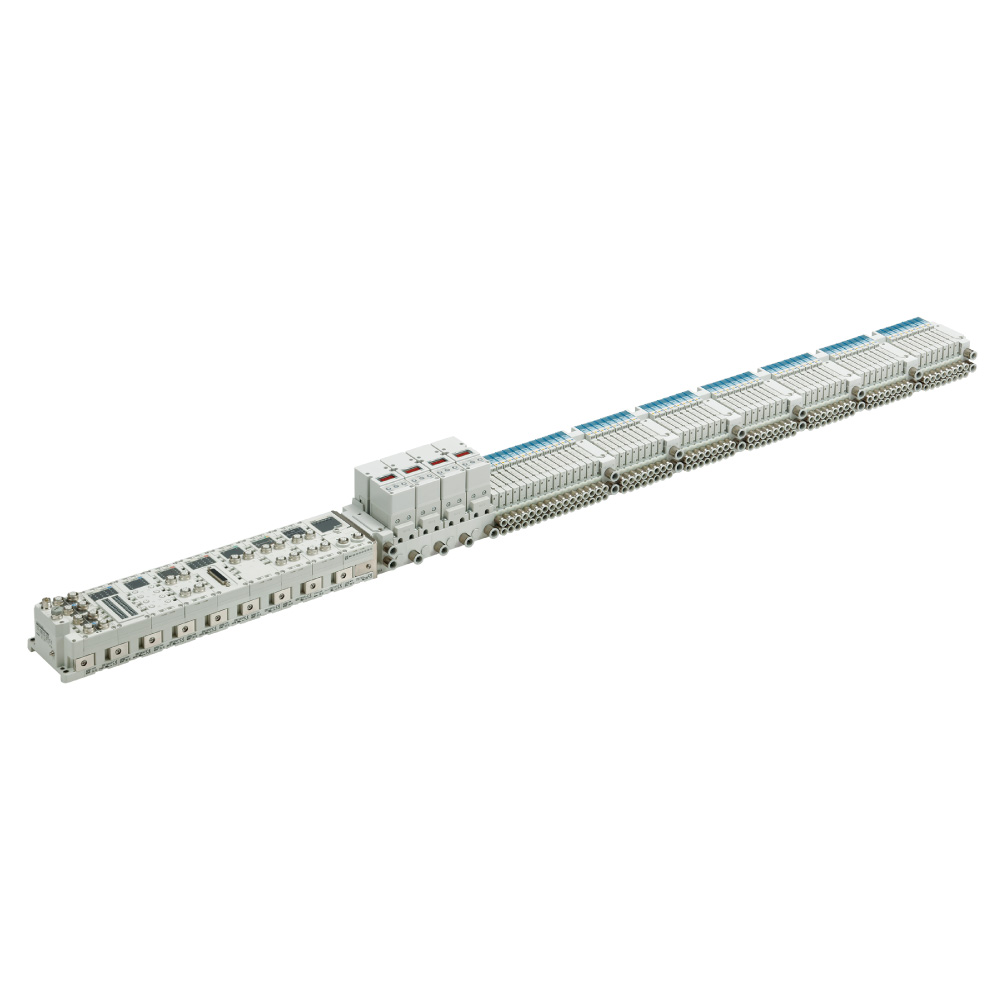

Electro-pneumatic Regulator Integrated Type 64-station Compatible Manifold Plug-in Compact 5-Port Solenoid Valve JSY3000-P

Directional Control Valves » Pilot Operated 4/5 Port Solenoid ValvesIndustrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: PROFINET Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherNet/IP Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherCAT Compatible Products

-

・Solenoid valves and electro-pneumatic regulators can be connected to

the same manifold.

Valve stations/Number of outputs: For 4 to 64 stations∗/128 points

∗ Stations are only available in multiples of 4.

Electro-pneumatic regulator stations: 1 to 4 stations

I/O unit stations: Max. 8 stations

・Equipment integration allows for the centralized management of control

and wiring as well as reduced wiring

Reduced wiring, Reduced number of SI units, Reduced wiring work,

Compact

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Enclosure | Communication protocol | Applicable devices |

|---|---|---|---|

| JSY3000-P | IP65 | PROFINET EtherNet/IP™ EtherCAT | SI unit: EX600 Valve: JSY3000 Electro-pneumatic regulator: ITV2340 |

Air Management System 25A-AMS20/30/40/60

Series Compatible with Secondary Batteries Series 25A- » Air Management System-

・Air consumption: Max. 62% reduction

Monitors the machine standby conditions (when production stops) and

automatically decreases the pressure.

Reduces unnecessary air consumption

・Compatible with OPC UA

Direct connection enables data communications.

・Compatible with wireless systems

Communication cables not required

High security thanks to unique encryption

Communication distance: Max. 100 m

・IO-Link compatible

| Series | Size | Port size | Flow capacity [L/min] | Communication protocol | Output data |

|---|---|---|---|---|---|

| Electro-Pneumatic Regulator Type

25A-AMS20A/30A/40A/60A | 20 30 40 60 | 1/8 1/4 3/8 1/2 3/4 1 | 5 to 500 10 to 1000 20 to 2000 40 to 4000 | PROFINET EtherNet/IP™ OPC UA EtherCAT | Instantaneous flow Accumulated flow Pressure Fluid temperature Various sensor information transmitted via IO-Link Diagnosis |

| Regulator Type

25A-AMS20B/30B/40B/60B | 20 30 40 60 | 1/8 1/4 3/8 1/2 3/4 1 | 5 to 500 10 to 1000 20 to 2000 40 to 4000 | PROFINET EtherNet/IP™ OPC UA EtherCAT | Instantaneous flow Accumulated flow Pressure Fluid temperature Various sensor information transmitted via IO-Link Diagnosis |

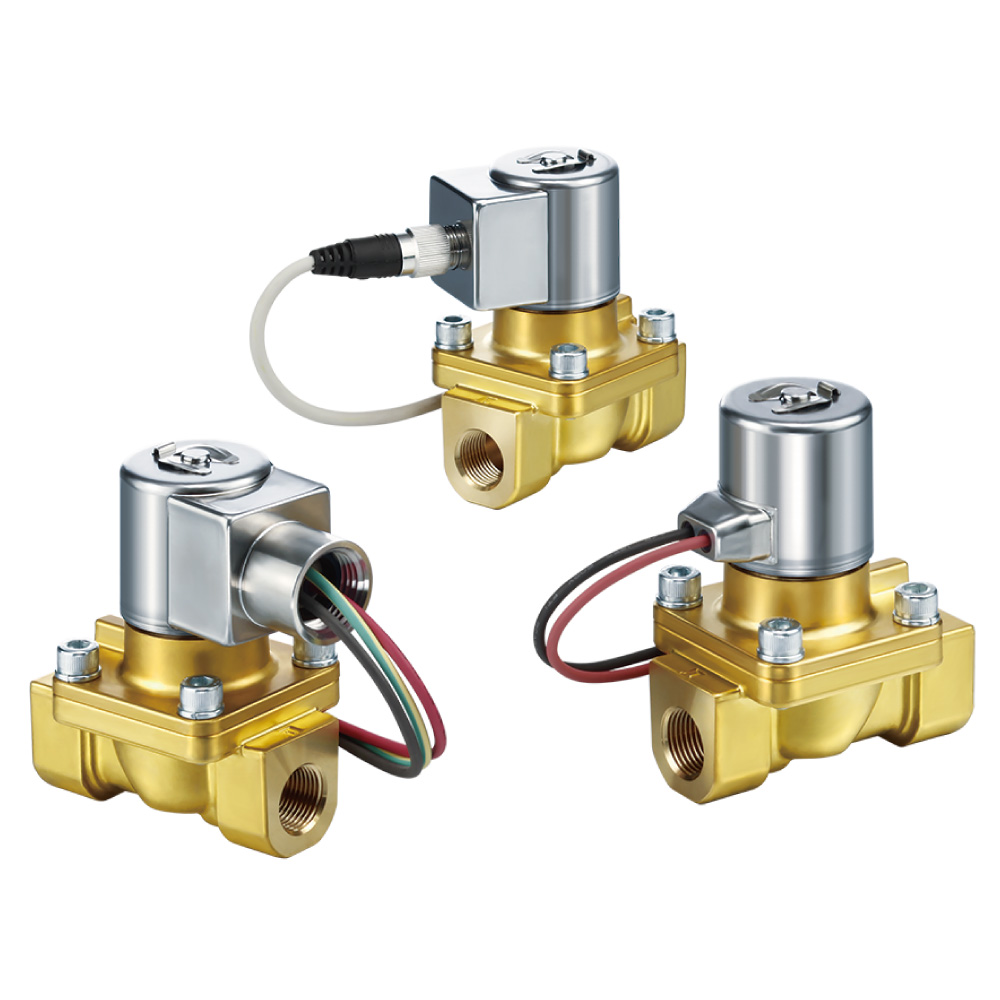

Pilot Operated 2-Port Solenoid Valve JSXH-X1

Process Valves » 2/3 Port Solenoid Valves/Air Operated Valves-

・Max. operating pressure differential: 4.0 MPa

Application examples: Blow molding, Laser processing machines,

Nitrogen filling unit

・Fluid: Compressed air, Nitrogen, Argon, Oxygen∗

∗ When using oxygen, please refer to "Fluid Supply."

・Improved environmental resistance

Dustproof/waterproof IP67 structure (IP65 for the DIN terminal)

With a stainless steel coil cover

・Low particle generation

・Oil-free

・Easy maintenance

The coil can be replaced by simply removing the clip.

・Power saving (Power consumption: 6 W)

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions Model Selection/Flow Rate Characteristics Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List Green Procurement (RoHS)

| Series | Type | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|---|

| JSXH-X1 | Pilot operated | N.C. | 3/8,1/2 | 16 |

Analog Auto Switch and Display Sensor Monitor D-MH1□

Rotary Actuators/Air Grippers » Auto SwitchesSwitches/Sensors/Controller » Auto Switches for Rotary Actuators and Air Grippers

-

・Outputs the analog voltage according to the actuator stroke position

・A single switch can discriminate between max. 3 position points.

Repeatability: ±20 mV (Converted stroke ±0.1 mm)

Discriminable dimensional difference: 0.2 mm

∗ The value is in the high-resolution range. The converted stroke value

varies depending on the actuator.

∗ For air grippers, this is the value for one side of the finger. When it is

converted to the dimension of the workpiece to be gripped, the value is

doubled.

・Detection position display and setting away from the actuator are

possible.

・Analog voltage output (1 to 5 V)

・Can also be used with the analog auto switch single unit

・Reduced setting labor

・No need to fine-tune the switch mounting position

・Easy adjustment even in narrow places and on moving parts

・Improved productivity

· Gripper fully open R gripping R gripping failure detection

· Minimized lead wire disconnection risk

· Preventive maintenance

· Display of gripper finger wear

· Visualization of daily inspections (Origin position/ Gripping position)

| Series | Type | Description |

|---|---|---|

| D-MH1AD(V) | Analog auto switch | Analog output sensor (1 to 5 V) |

| D-MH1BN | Sensor monitor | Display sensor monitor, NPN 2 outputs |

| D-MH1BP | Sensor monitor | Display sensor monitor, PNP 2 outputs |

Electric Gripper for Collaborative Robots LEHR

Electric Actuators/Cylinders » Grippers for Collaborative RobotsAir Gripper for Collaborative Robots » Electric Grippers

-

・Can be used with the collaborative robots of UNIVERSAL ROBOTS,

FANUC CORPORATION, and OMRON/TECHMAN ROBOT

・2 variations are available.

・Gripping force: 60 to 140 N

・Operate by simply connecting 1 electrical wire

・Annual CO2 emissions reduced by up to 52% through motor control

optimization (SMC comparison)

・With internal battery-less absolute encoder

・Easy tool changing (Manual changer)

・Compatible plug-in software: URCap

| Type | Series | Opening/Closing stroke [mm] | Gripping force [N] |

|---|---|---|---|

| For collaborative robots | LEHR | 50 | 60 to 140 |

Push-lock Type Dual Speed Controller with One-touch Fitting ASD-A

Flow Control Equipment » Speed Controllers for General Purposes-

・Easy to lock push-lock type

・No tools required. Larger knob

・Allows for simultaneous meter-in and meter-out control

・Prevents cylinders from popping out, and allows for the

speed control of single acting cylinders

・Easy identification of meter-in or meter-out by knob color

・Lightweight: Approx. 28% lighter

・Improved reproducibility of flow rate

| Type | Series | Port size on the cylinder side | Applicable tubing O.D. Metric size | Applicable tubing O.D. Inch size |

|---|---|---|---|---|

| Dual speed controller | ASD-A | M5 to 1/2 | φ4 to φ12 | φ1/8'' to φ3/8'' |

3-Screen Display Condensation Checker (Digital Temperature & Humidity Switch) PSH

Switches/Sensors/Controller » Electronic Temperature & Humidity Switches-

・A relative humidity under pressure (inside piping) display function has

been added. New

・A condensation checker can prevent such problems!

Allows for the visualization of humidity inside piping

Detects abnormalities prior to condensation generation

・Can be easily connected to any pipe you want to monitor

Compact size allows for easy installation

・Visualization of relative humidity

Real-time monitoring

・Remote/Condition monitoring

Remote confirmation via switch output preventing condensation

problems!

Safety Instructions Pressure Switches/Flow Switches/Precautions Pressure Switch Series Variations/Application Example Glossary of Terms/Technical Information Green Procurement (RoHS) Proposal for Condensation Checker Installation

| Series | Set temperature range | Set relative humidity range | Display accuracy |

|---|---|---|---|

| PSH | -5 to 55°C | 0 to 100% R.H. (No condensation) | Temperature: ±3°C ±1 digit Humidity: ±5% R.H. ±1 digit |

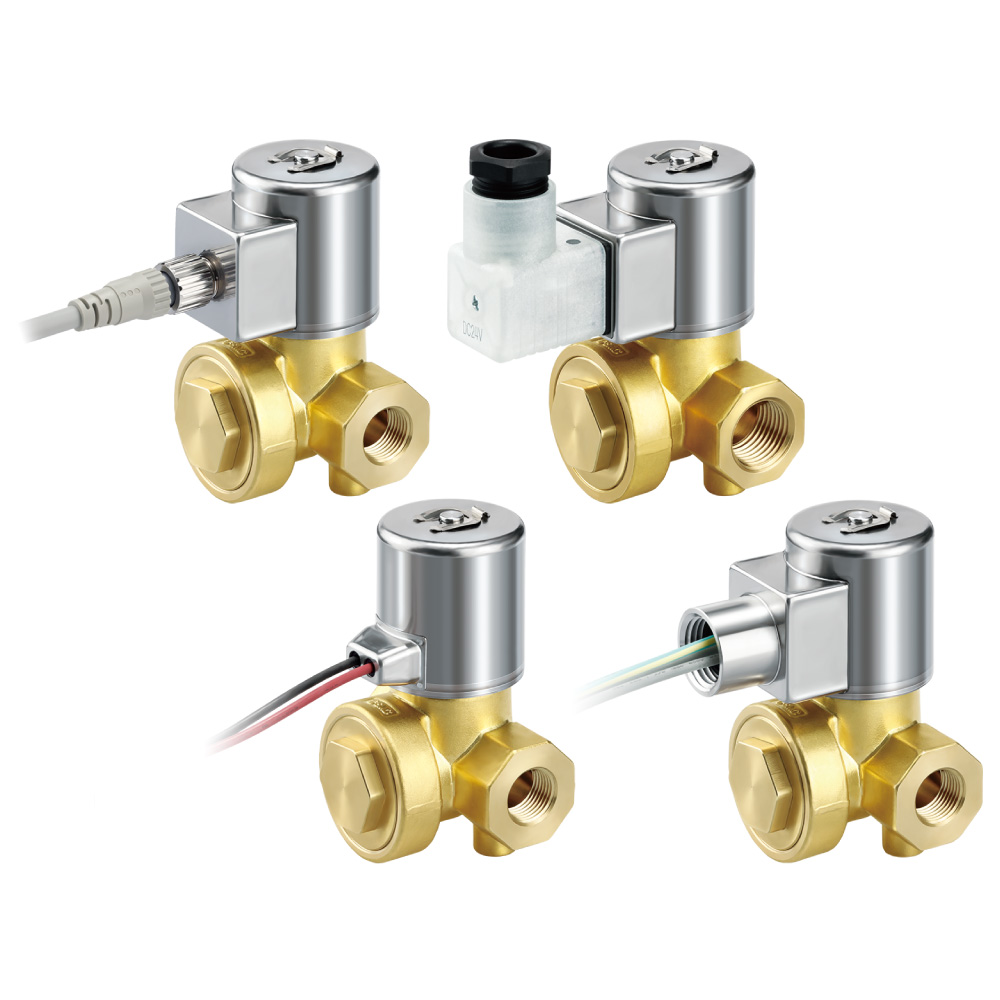

[For High-Pressure Water] Pilot Operated 2-Port Solenoid Valve JSXH-X2

Process Valves » 2/3 Port Solenoid Valves/Air Operated Valves-

・Can be used at up to 10 MPa

For high-pressure washing, water spraying, and misting

・An IP67 structure with improved environmental resistance

(The DIN terminal is IP65.)

・Orifice diameter [mmø]: 12

・Flow rate characteristics [Kv]: 1.7 (Port size 3/8), 1.9 (Port size 1/2)

・Easy maintenance

The coil can be replaced by simply removing the clip.

・Power consumption: 8 W

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions Model Selection/Flow Rate Characteristics Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List Green Procurement (RoHS)

| Series | Type | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|---|

| JSXH-X2 | Pilot operated | N.C. | 3/8,1/2 | 12 |

Membrane Nitrogen Generator IN778-1/IN778-2

Gas Generator » Gas Generator-

・Nitrogen enriched air purification is easily possible with only

a compressed air supply.

・Nitrogen concentration: Max. 99.9 or more/ Outlet air flow rate: 20 L/min

(ANR)※

※Inlet air pressure: 0.7 MPa, Inlet air temperature 25°C

・Compact and easy to use at point of use

・No power supply required

・No need for gas cylinder replacement

・Modular connection type

・Outlet side compressed air purity class (Humidity)"2"※

※For IN778-1

| Series | Inlet air conditions | Nitrogen enriched outlet air flow rate L/min(ANR) | Nitrogen concentration % | Proof pressure Mpa | Max. operating pressure Mpa | Min. operating pressure Mpa |

|---|---|---|---|---|---|---|

| IN778-1 | 25℃ 0.7MPa | 20 | 99.9 | 1.5 | 1.0 | 0.3 |

| IN778-2 | 25℃ 0.7MPa | 20 | 98 | 1.5 | 1.0 | 0.3 |

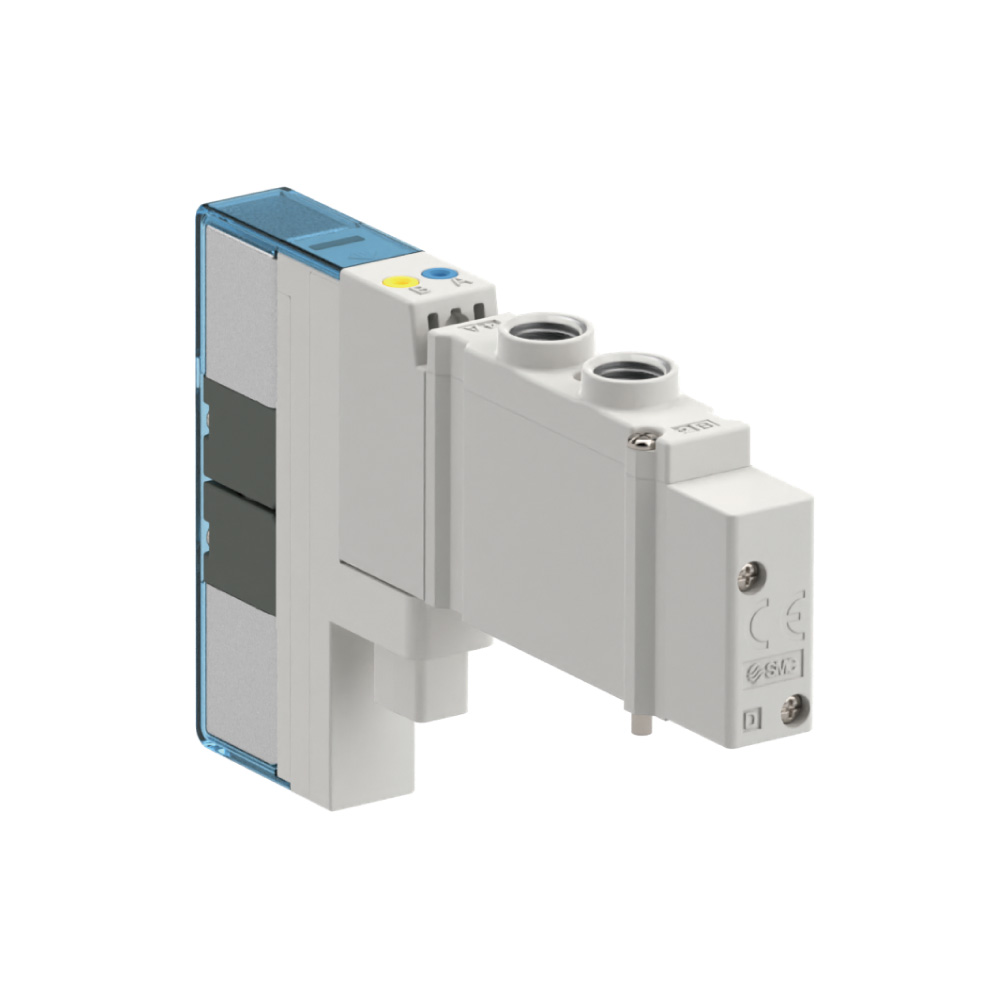

Plug-in Top Ported Compact 5-Port Solenoid Valve JSY3000

Directional Control Valves » Pilot Operated 4/5 Port Solenoid Valves-

・A top-ported type has been added to the JSY3000 series.

・4(A) and 2(B) port output pressure detection is possible.

Caution: The mounting bases are side ported.

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | 4(A)/2(B) port size Thread piping | Power consumption [W] |

|---|---|---|

| JSY3000 | Rc1/16 | 0.4 (Standard) 0.1 (With power-saving circuit*) *Made to order |