There were 174 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Electro-Pneumatic Transducer IT600/601

Pneumatic Instrumentation Equipment » Electro-Pneumatic Transducers

-

・Air pressure in proportion to the current signal can be output.

・Wide output pressure range: 0.02 to 0.6 MPa

・Fast response

・Independent electric unit/Explosion-proof (flameproof) construction

・Easy span adjustment

| Series | Port size | Supply air pressure (MPa) | Input current |

|---|---|---|---|

| IT600 | Rc1/4 | 0.14 to 0.24 | 4 to 20 mA DC |

| IT601 | Rc1/4 | 0.24 to 0.7 | 4 to 20 mA DC |

Vinyl Chloride Air Operated Valve LVP

Chemical Liquid Valves/Fittings & Needle Valves/Tubing » Chemical Liquid ValvesFluoropolymer Equipment/PVC Equipment » PVC Valves

-

・Applicable to rigid vinyl chloride tubes: Union type with PVC unfixed

union

・Body material: CPVC, Diaphragm material: PTFE

・O-ring materials: FKM, EPDM (Selectable)

・Applicable fluids: Deionized water, Chemical liquids

| Series | Applicable tubing O.D. | Orifice diameter (mmø) | Valve type | Option |

|---|---|---|---|---|

| LVP5□ | O.D. ø22 (Nominal dia. 16 A) | 16 | N.C./N.O./ Double acting | With flow rate adjustment |

| LVP6□ | O.D. ø26 (Nominal dia. 20 A) | 22 | N.C./N.O./ Double acting | With flow rate adjustment |

| LVP6□ | O.D. ø32 (Nominal dia. 25 A) | 22 | N.C./N.O./ Double acting | With flow rate adjustment |

High Purity Chemical Liquid Valve/Air Operated, Integrated Fitting Type LVC

Chemical Liquid Valves/Fittings & Needle Valves/Tubing » Chemical Liquid ValvesFluoropolymer Equipment/PVC Equipment » High Purity Chemical Liquid Valves

-

・Body material: New PFA

・N.C./N.O./Double acting all feature the same configuration.

・Compatible with fluid temperatures of 100℃

・Manifold type no.: LLC2, LLC3, LLC4, LLC5

| Series | Type | Valve type | Applicable tubing O.D. | Orifice diameter (mmø) |

|---|---|---|---|---|

| LVC | Air Operated Integrated fitting | N.C./N.O./ Double acting | Metric: 3 to 25 Inch: 1/8 to 1 | 4 to 22 |

Valve for Water and Chemical Base Fluids (2/3-Port Air Operated Valve) VCC

Process Valves » Valves for Water and Chemical Base Fluids

-

・Applicable for 2 liquid paints (VCC12D)

PTFE diaphragm structure = Elimination of sliding parts

Less paint adhesion

・Mountable on a robot arm (Space saving, Lightweight)

2 valves per station (30 mm pitch)

2/3-port valves mixed mounting

Resin manifold block

| Series | Orifice diameter | Fluid |

|---|---|---|

| VCC | φ3.8 | Water/chemical-based paint, Ink, Cleaning fluid (Water, Butyl acetate), Air |

Coolant Valve (2 Way Valve)/Low Power Consumption, High Flow Type SGC

Process Valves » Coolant Valves-

・High flow type to control coolants (Cutting fluid) in machine tools

・Low power consumption: 0.35 W (at 24 VDC)

・Maximum operating pressure: 0.5 MPa, 1 MPa, 1.6 MPa

・Service life: 5 million cycles or more (Based on SMC's test conditions)

・CE-compliant

・Compatible with G threads (ISO1179-1) as standard

・Air operated, external pilot solenoid

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics Series Variations/Process, Coolant Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics Series Variations/Process, Coolant Valves List

Green Procurement (RoHS)

| Series | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|

| SGC | N.C./N.O. | 3/8 to 2 | 9 to 51 |

Process Valve/2 Port Valve (2 Way Valve) for Compressed Air and Air-hydro Circuit Control VNA

Process Valves » 2/3 Port Valves for General Purpose Fluid Control

-

・Exclusively for pneumatic systems and air-hydro circuit controls

・The balance poppet permits normal and reverse flow.

・Air operated, external pilot solenoid

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics Series Variations/Process, Coolant Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics Series Variations/Process, Coolant Valves List

Green Procurement (RoHS)

| Series | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|

| VNA | N.C./N.O./C.O. | 1/8 to 2 | 10 to 50 |

5.0 MPa Pilot Operated 2/3-Port Solenoid Valve & Check Valve VCH/VCHC

Process Valves » 5.0 MPa 2/3 Port Solenoid Valves

-

・Service life: 10 million cycles

・Uses a polyurethane elastomer poppet for valve parts

・Improves durability at high pressures

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics Series Variations/Solenoid Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics Series Variations/Solenoid Valves List

Green Procurement (RoHS)

| Series | Type | Port size | Orifice diameter (mmø) |

|---|---|---|---|

| VCH41 | 2-port valve, N.C. | G3/4, 1 | φ16 |

| VCH42 | 2-port valve, N.O | G3/4, 1 | φ17.5 |

| VCH410 | 3-port valve | G1/2 to 1 | φ18 |

| VCHC40 | Check valve | G3/4, 1 | φ16 |

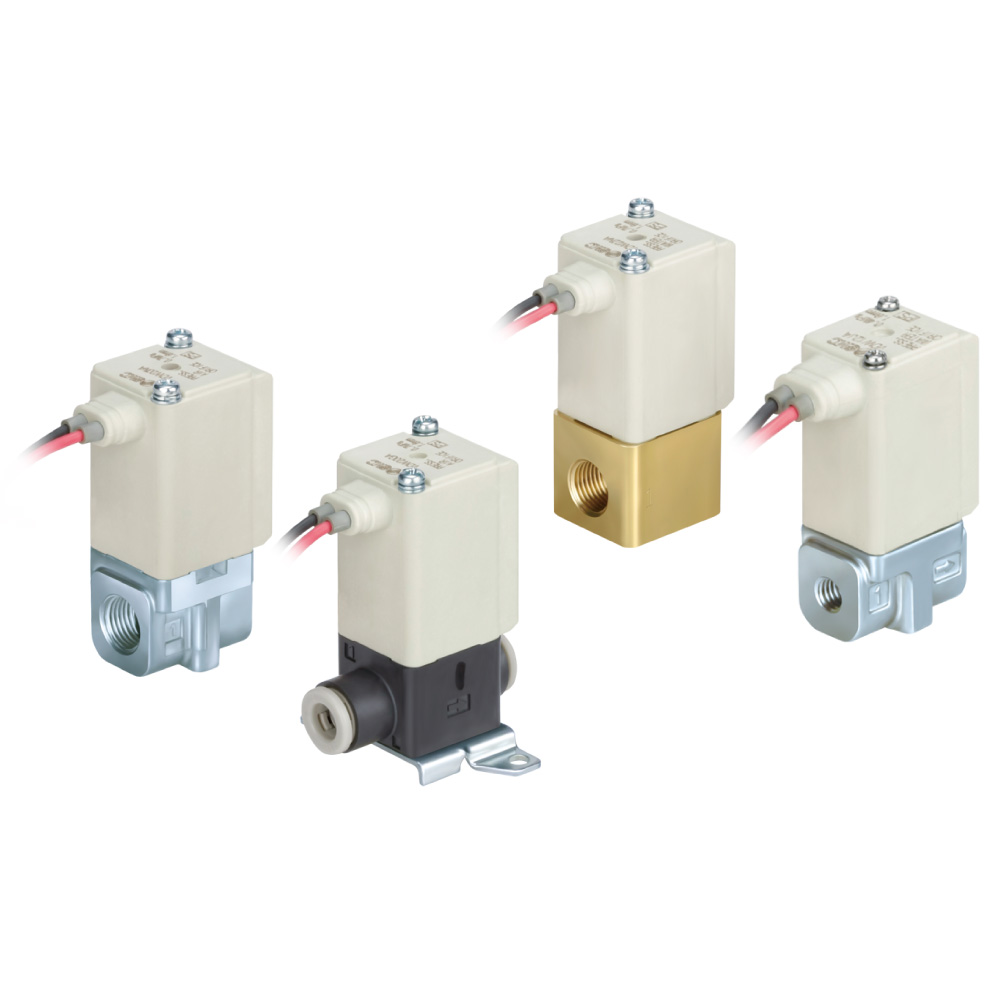

Compact Direct Operated 2 Port Solenoid Valve (2 Way Valve) VDW

Process Valves » Compact 2/3 Port Solenoid Valves/Air Operated ValvesEquipment for the Semiconductor Industries » Cooling Water Line

-

・For air, medium vacuum, water

・Body material: Aluminum, Resin (PPS), Brass, Stainless steel

・With One-touch fittings (resin body)

・IP65

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics Series Variations/Solenoid Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics Series Variations/Solenoid Valves List

Green Procurement (RoHS)

| Series | Valve type | Port size | Orifice diameter |

|---|---|---|---|

| VDW10/20 | N.C. | φ3.2, φ4, φ6, M5, 1/8 | φ1 to φ3.2 |

Direct Operated/Pilot Operated 2-Port Solenoid Valve JSX/JSX□

Process Valves » 2/3 Port Solenoid Valves/Air Operated ValvesEquipment for the Semiconductor Industries » Cooling Water Line

-

· Zero Differential Pressure Type Pilot Operated 2-Port Solenoid Valve

JSXZ Series has been added. New

· Improved environmental resistance due to the stainless steel coil cover

[IP67 enclosure/NEMA4X∗] ∗ IP65 for models with a DIN terminal

·Space saving

Compact: Valve volume reduced by 25%*, Lightweight: Weight reduced

by 30%*

* Compared with the existing model

·Energy saving

Coil force: 10% increase*, Power consumption: 14% reduction*

* Compared with the existing model

·360° lead wire insertion and removal is possible.

·Improved weather resistance in outdoor environments

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics

Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics

Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List

Green Procurement (RoHS)

| Series | Type | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|---|

| JSX | Direct operated | N.C/N.O. | 1/8, 1/4, 3/8 | 1.6 to 7.1 |

| JSX□□U | Direct operated high flow/ power saving type | N.C. | 1/8, 1/4, 3/8 | 2.4 to 7.1 |

| JSX□□V | Direct operated vacuum type | N.C. | 1/8, 1/4, 3/8 | 5.6 to 7.1 |

| JSX□□H | Direct operated high pressure type | N.C. | 1/4, 3/8 | 3.2 |

| JSX□□S | Direct operated steam type | N.C. | 1/4, 3/8 | 1.6,7.1 |

| JSXM | Direct operated modular mounting type | N.C. | 1/8,1/4,3/8,1/2 | 3.2,4 |

| JSXD | Pilot operated | N.C./N.O. | 1/4,3/8,1/2,3/4,1,1·1/4,1·1/2,2,32A,40A,50A | 10 to 50 |

| JSXP | Steam type | N.C. | 3/8,1/2,3/4,1,1·1/4,1·1/2,2,32A,40A,50A | 15 to 50 |

| JSXZ | Zero differential pressure type pilot operated | N.C. | 1/4,3/8,1/2,3/4,1 | 10 to 25 |

Air Saving Speed Controller AS-R/AS-Q

Flow Control Equipment » Air Saving Speed Controllers Air Saving Valves-

・Reduce air consumption just by mounting to an air cylinder.

・Air consumption reduced by 25%

・Mounting and operation are the same as regular speed controller.

・Equal response time

No delay of response time with 2-pressure control

・Compact: 85% reduction

The functions of the regulator and speed controller have been integrated.

| Type | Series | Port size on the cylinder side | Applicable tubing O.D. Metric size | Applicable tubing O.D. Inch size |

|---|---|---|---|---|

| Elbow type With pressure reduction function | AS22R to AS42R | R, NPT, G 1/8 to 1/2 | φ6 to φ12 | φ1/4'' to φ1/2'' |

| Elbow type With rapid supply and exhaust function | AS22Q to AS42Q | R, NPT, G 1/4 to 1/2 | φ6 to φ12 | φ1/4'' to φ1/2'' |