There were 174 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

FR Three-layer Polyurethane Tubing TRTU

Fittings and Tubing » Tubing(Tubing for Special Environments)Arc Welding Process Equipment » Tubing/Fittings/Flow Control Equipment

-

・Spatter resistance has been improved by installing an aluminum layer between the outer layer and the inner tube.

(It is twice that of the TRBU series FR double layer polyurethane tubing.)

・For general pneumatic and water piping in environments exposed to sparks from arc welding, etc.

・Flame resistant (Equivalent to UL-94 Standard V-0)

| Series | Tubing O.D. | Color | Fluid |

|---|---|---|---|

| TRTU | φ6,φ8,φ10,φ12 | Black, White, Red, Blue, Yellow, Green | Air, Water |

FR Soft Nylon Tubing TRS

Fittings and Tubing » Tubing(Tubing for Special Environments)-

・Max. operating pressure: 1.2 MPa (at 20℃)

・For use in spatter-generating atmospheres/Flame resistant

(Equivalent to UL-94 Standard V-0)

Safety Instructions Fittings and Tubing/Precautions Series Variations Improved Weather Resistance Tube Green Procurement (RoHS)

| Series | Tubing O.D. | Color | Fluid |

|---|---|---|---|

| TRS | φ6,φ8,φ10,φ12 | Black, White, Red, Blue, Green | Air, Water |

FR One-touch Fittings KR-W2

Fittings and Tubing » Fittings for Special Environments

-

・For use where weld spatter is generated/Flame resistant

(Equivalent to UL-94 Standard V-0)

・Flame resistant spatter cover (KR-□C-X1807)

| Series | Applicable tubing O.D. | Connection thread |

|---|---|---|

| KR-W2 | φ6,φ8,φ10,φ12 | 1/8,1/4,3/8,1/2 |

Thermo-dryer with Air Temperature Adjustment Function IDH□

Air Preparation Equipment » Air DryersTemperature Control Equipment » Air Temperature Controllers

-

・Stable supply of temperature and pressure controlled dry clean air

Can supply compressed air with the same conditions and quality

regardless of the season

・Application example:

Supplying compressed air with constant conditions to air bearings

mounted on a tool

・Built-in filter

Nominal filtration: 0.01 μm (99.9% filtration efficiency)

Outlet oil mist concentration: Max. 0.01 mg/m3 (ANR)

Outlet cleanliness: Particles of 0.3 μm or more: 3.5 particles/L (ANR)

or less

・Compatible with power supplies from around the world Single-phase

100, 200, 230 VAC (50/60 Hz)

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Series | Air flow capacity L/min(ANR) | Outlet air temperature adjustment range | Outlet air set pressure range | Outlet air temperature stability | Cooling method | Compressor output |

|---|---|---|---|---|---|---|

| IDH□4 | 100 to 500 | 15 to 30℃ | 0.15 to 0.85 MPa | ±0.1 | Heater operation PID control | Less than 7.5kw |

| IDH□6 | 200 to 800 | 15 to 30℃ | 0.15 to 0.85 MPa | ±0.1 | Heater operation PID control | Less than 7.5kw |

Vacuum Gripper for Collaborative Robots ZXP7□21-X1

for the FANUC CORPORATION CRX Series

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Gripper for Collaborative RobotsAir Gripper for Collaborative Robots » Vacuum Grippers

-

・Plug and Play configuration for immediate use

・FANUC CRX plug-in software

・Operate by simply connecting 1 compressed air supply tube and an electrical wiring M8 connector.

・Integrated vacuum ejector, air supply/release valve, pressure sensor, and cups

・Standards: Conforming to ISO 9409-1-50-4-M6

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Cup form | Cup diameter | Suction flow rate [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|---|

| ZXP7□21-X1 | Flat Flat with rib Bellows Thin flat Multistage bellows 2.5-stage bellows 5.5-stage bellows | φ8 to φ32 | 17 | 57 |

Basic Vacuum Pad (Vacuum Suction Cup) ZP

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Pads (Vacuum Suction Cups)

-

・12 sizes, 6 types of pad forms

The mounting bracket can be selected according to the application.

・Pad form: Flat type, Flat type with ribs, Bellows type,

Thin flat type, Thin flat type with ribs, Deep type

・Mounting: Male thread, Female thread

・Vacuum inlet direction: Vertical, Lateral

・Vacuum inlet: Male thread, Female thread, One-touch fitting, Barb fitting

・Buffer: Without, With

[Buffer stroke [mm]: 6, 10, 15, 20, 25, 30, 40, 50]

Safety Instructions Vacuum Equipment/Precautions Vacuum Pads/Precautions Series Variations Model Selection Mounting Bracket Assembly (p.121-130) Green Procurement (RoHS)

| Series | Pad form | Pad diameter(mm) |

|---|---|---|

| ZP | Flat type | φ2,φ4,φ6,φ8,φ10,φ13,φ16, φ20,φ25,φ32,φ40,φ50 |

| ZP | Flat type with ribs | φ10,φ13,φ16,φ20,φ25,φ32,φ40,φ50 |

| ZP | Flat type (Ball joint) | φ10,φ13,φ16,φ20,φ25,φ32,φ40,φ50 |

| ZP | Bellows type | φ6,φ8,φ10,φ13,φ16, φ20,φ25,φ32,φ40,φ50 |

| ZP | Thin flat type | φ10,φ13,φ16 |

| ZP | Thin flat type with ribs | φ10,φ13,φ16 |

| ZP | Deep type | φ10, φ16, φ25, φ40 |

Vacuum Ejector ZH

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors-

・Compact and lightweight

Overall length: Max. 11% reduction (6.7 mm shorter) [Body ported type]

Port height: Max. 25% reduction (9.1 mm shorter) [Body ported type]

Weight: Max. 74% reduction (65.1 g lighter) [Body ported type]

Volume: Max. 39% reduction (14.1 cm3 reduction) [Box type]

・4 mounting types:

Direct mounting, Standard bracket mounting, L-bracket mounting,

DIN rail mounting

・A silencer and standard bracket are available. (Body ported type only)

| Body type | Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) |

|---|---|---|---|---|---|

| Body ported type | ZH05DSA | 0.5 | 6 | 13 | 2 to 13 |

| Body ported type | ZH07DSA | 0.7 | 12 | 27 | 2 to 20 |

| Body ported type | ZH10DSA | 1.0 | 26 | 52 | 2 to 32 |

| Body ported type | ZH13DSA | 1.3 | 40 | 88 | 2 to 50 |

| Body ported type | ZH15DSA | 1.5 | 58 | 117 | 2 to 100 |

| Body ported type | ZH18DSA | 1.8 | 76 | 165 | 2 to 125 |

| Body ported type | ZH20DSA | 2.0 | 90 | 201 | 2 to 150 |

| Box type (Built-in silencer) | ZH05B□A | 0.5 | 6 | 13 | 2 to 13 |

| Box type (Built-in silencer) | ZH07B□A | 0.7 | 12 | 27 | 2 to 20 |

| Box type (Built-in silencer) | ZH10B□A | 1.0 | 26 | 52 | 2 to 32 |

| Box type (Built-in silencer) | ZH13B□A | 1.3 | 40 | 88 | 2 to 50 |

| Box type (Built-in silencer) | ZH15B□A | 1.5 | 58 | 117 | 2 to 100 |

| Box type (Built-in silencer) | ZH18B□A | 1.8 | 76 | 165 | 2 to 125 |

| Box type (Built-in silencer) | ZH20B□A | 2.0 | 90 | 201 | 2 to 150 |

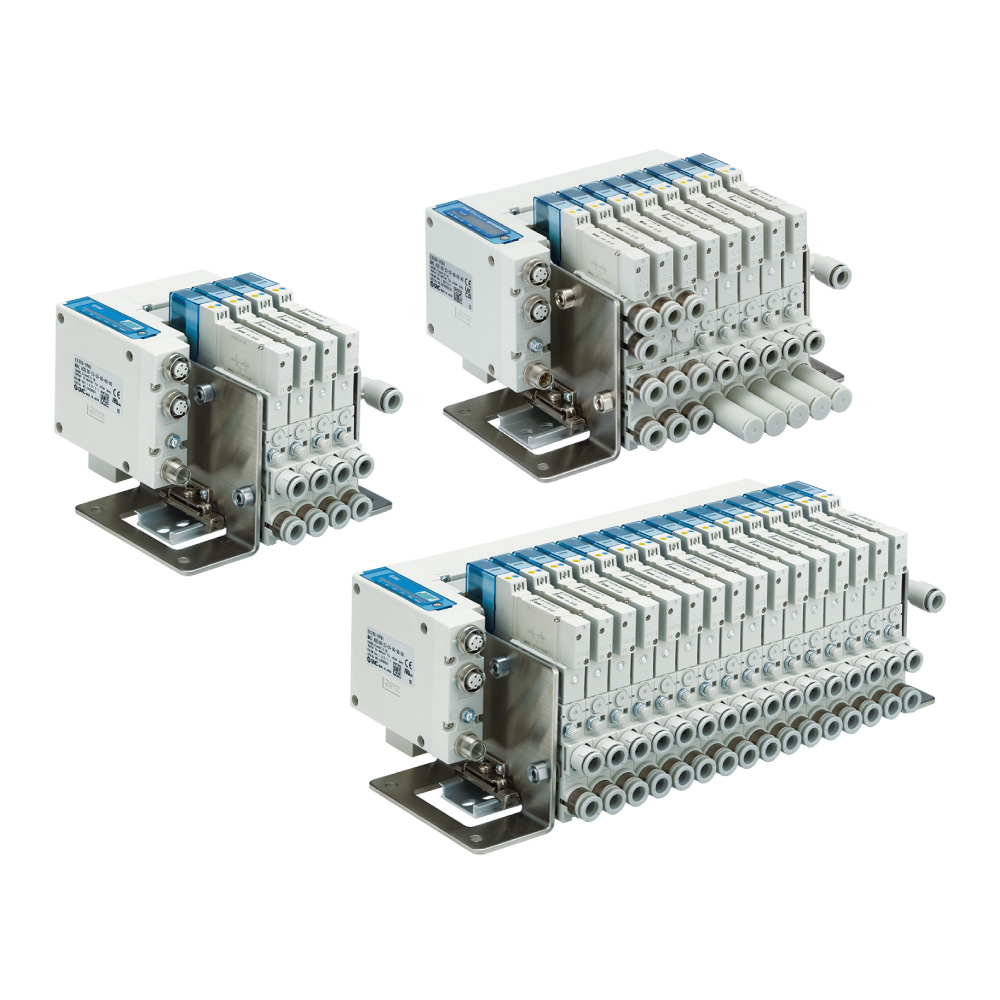

Vacuum Manifold for Fieldbus System ZKJ

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump SystemsIndustrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: PROFINET Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherNet/IP Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: IO-Link Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherCAT Compatible Products

IO-Link Devices » Vacuum Unit/Vacuum Manifold

-

・Vacuum pads and actuator driving can be controlled with a single

manifold [New]

・Positive pressure unit [New]

5-port solenoid valve

・Vacuum unit

Energy saving ejector Air consumption: 92% reduction

・Fieldbus compatible

Space saving: Requires no separate input/output units

Reduced wiring time

Compatible protocols: PROFINET, IO-Link, EtherNet/IP, EtherCAT

・Exhaust sealing function

Quick workpiece release

・4 stations/8 stations/12 stations/16 stations manifold compatible

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|

| ZKJ07 | 0.7 | 31 | 26 |

| ZKJ10 | 1.0 | 53 | 48 |

| ZKJ12 | 1.2 | 63 | 68 |

| ZKJ15 | 1.5 | 74 | 102 |

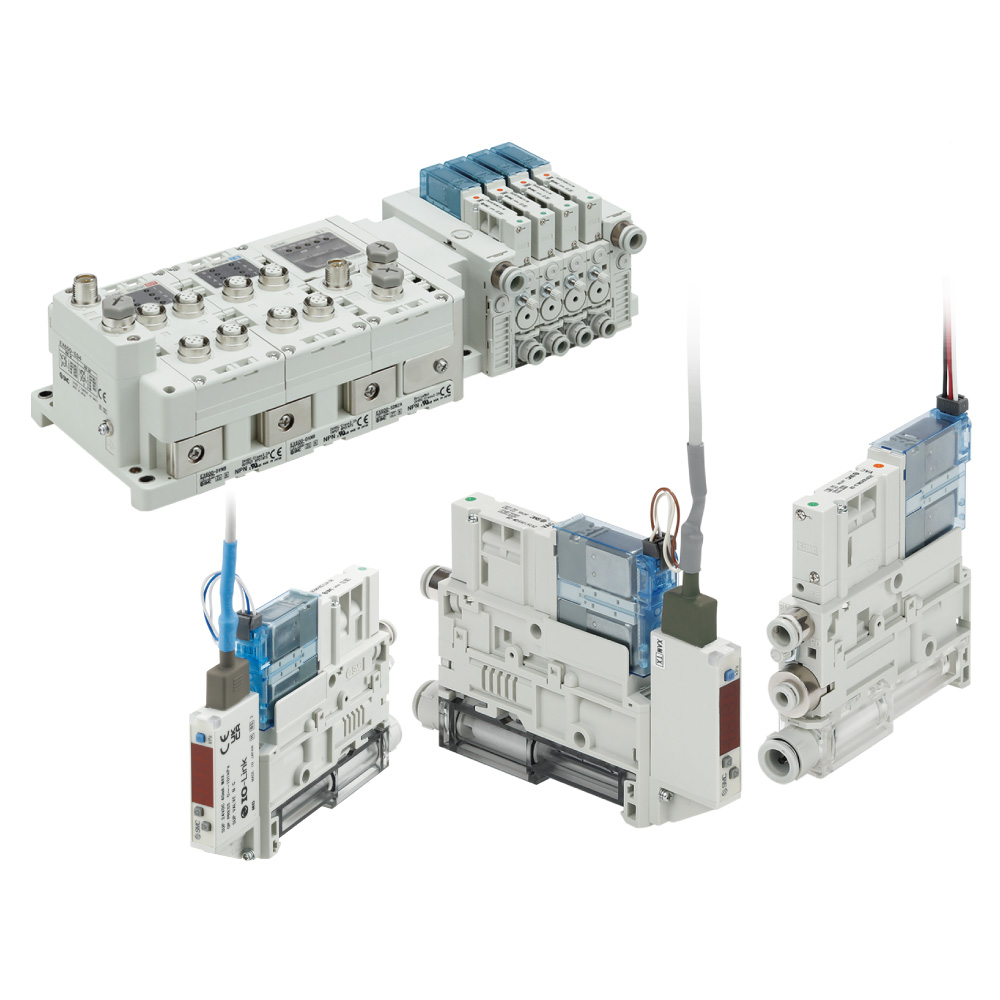

Vacuum Unit (Vacuum Generators) ZK2□A

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems-

・Supply valve: An N.O. specification has been added.

Can hold vacuum∗ even when the power goes out or is turned off

Prevents the sudden dropping of workpieces∗

∗ Supposing the supply pressure is being maintained

・An IO-Link compatible pressure switch has been added.

Allows for ejector control with a single communication line

Reading of the device information and parameter batch settings are

possible.

・Compatible with ejector systems and vacuum pump systems

・Energy saving ejector

Air supply is cut-off when vacuum is reached.

Air consumption: 93% reduction (Under SMC’s measurement conditions)

・More efficient ejector: Suction flow increased by 50% (Compared to other

SMC 1-stage ejectors)

・Energy saving efficiency: 93% reduction

・Improved low noise and suction flow by adoption of a high-noise

reduction silencer

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZK2□07 | 0.7 | 29 | 24 | 2 to 40 | ZK2□00 |

| ZK2□10 | 1.0 | 44 | 40 | 2 to 50 | ZK2□00 |

| ZK2□12 | 1.2 | 61 | 58 | 2 to 125 | ZK2□00 |

| ZK2□15 | 1.5 | 67 | 90 | 2 to 150 | ZK2□00 |

Rotary Actuator CRB/CDRB

Rotary Actuators/Air Grippers » Rotary Actuators Vane Type-

・A double vane type has been added for sizes 10 to 40. [New]

・Features a compact body with a built-in angle adjustment unit and auto

switch unit (Size: 20, 30, 40)

Overall length: 44% shorter, Weight: 48% lighter

・Piping, wiring, and angle adjustment can be performed on the same side

for easier mounting.

・Easy-to-adjust start and end positions with the angle adjustment bolts

(as standard)

・The position of the chamfered portion of the shaft can be easily checked

usingthe rotating angle indicator. (Only for the CDRB with auto switch)

・Each of the units below for the CRB2 series can be mounted to the CRB

series.

Safety Instructions Rotary Actuators/Precautions Auto Switches/Precautions

Rotary Actuators Series Variations/Model Selection Quick Selection Table

Green Procurement (RoHS)

Rotary Actuators Series Variations/Model Selection Quick Selection Table

Green Procurement (RoHS)

| Type | Series | Vane type | Size | Rotating angle Single | Rotating angle Double |

|---|---|---|---|---|---|

| Standard (Without auto switch) | CRB | Single,Double | 10,15,20,30,40 | 90°,180°,270° | 90°,100° |

| Standard (With auto switch) | CDRB | Single | 10,15,20,30,40 | 90°,180° | - |

| With vertical auto switch unit | CRB□-A | Single,Double | 10,15,20,30,40 | 90°,180°,270° | 90°,100° |

| With angle adjustment unit | CRB□-B | Single,Double | 10,15,20,30,40 | 90°,180°,270° | 90°,100° |

| With vertical auto switch unit With angle adjustment unit | CRB□-C | Single,Double | 10,15,20,30,40 | 90°,180°,270° | 90°,100° |