There were 174 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Compact Position Sensor D-MPG

Air Cylinders » Actuator Position SensorIO-Link Compatible Products » Position Sensor

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: IO-Link Compatible Products

Rotary Actuators/Air Grippers » Position Sensor

Switches/Sensors/Controller » Position Sensor

-

・Detects the stroke position of compact actuators such as air grippers

・Repeatability: 0.1 mm

・Compact sensor head and separate teach unit

・Same shape as the D-M9□ solid state auto switch

・Analog output

・Switch output

・IO-Link compatible

▶IO-Link Devices

| Series | Measurement range | Resolution | Repeatability |

|---|---|---|---|

| D-MPG | 25 mm ±1 | 0.01 mm | 0.1 mm |

[Low GWP Refrigerant Chiller] Thermo-chiller Standard Type HRSF

Temperature Control Equipment » Chiller Compliant RegulationsEquipment for the Semiconductor Industries (Temperature Adjustment Line) » Chiller Compliant Regulations

Temperature Adjustment Line » Chiller Compliant Regulations

-

・Low GWP Refrigerant Chiller

GWP: 146∗ ∗ Regulation (EU) 2024/573, AIM Act 40 CFR Part 84

EU refrigerant regulations: GWP150 or more

US refrigerant regulations: GWP700 or more

California, US refrigerant regulations: GWP750 or more

・Environmentally friendly R454C as refrigerant (Not available for air

transport)

・No heater is required, as the circulating fluid is heated using only the heat

exhausted by the refrigerating circuit.

・Compatible with power supplies in Europe, Asia, Oceania, and North,

Central, and South America

・3-phase 400 VAC Low-noise design 70 dB(A)

・Outdoor installation IPX4

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRSF012 to 060 | 5 to 40℃ | 1.3 kW, 1.9 kW, 2.4 kW, 3.2 kW, 5.9 kW (60 Hz) | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water 15 to 40% Ethylene glycol aqueous solution Deionized water |

[Low GWP Refrigerant Chiller] Thermo-chiller Standard Type HRSF150/200

Temperature Control Equipment » Chiller Compliant RegulationsEquipment for the Semiconductor Industries (Temperature Adjustment Line) » Chiller Compliant Regulations

Temperature Adjustment Line » Chiller Compliant Regulations

-

・Low GWP Refrigerant Chiller

GWP: 146∗ ∗ Regulation (EU) 2024/573, AIM Act 40 CFR Part 84

EU refrigerant regulations: GWP150 or more

US refrigerant regulations: GWP700 or more

California, US refrigerant regulations: GWP750 or more

・Environmentally friendly R454C as refrigerant (Not available for air

transport)

・No heater is required, as the circulating fluid is heated using only the heat

exhausted by the refrigerating circuit.

・Compatible with power supplies in Europe, Asia, Oceania, and North,

Central, and South America

・3-phase 400 VAC Low-noise design 70 dB(A)

・Outdoor installation IPX4

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRSF150 HRSF200 | 5 to 35℃ | 15.7kW 20.5kW (Air-cooled) 20.6kW (Water-cooled) | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water 15 to 40% Ethylene glycol aqueous solution Deionized water |

Longer Life Cylinder C55-XB24

Air Cylinders » ISO Cylinders: ISO Standards (21287)-

・New technology offers at least 4 times better durability.

The maintenance intervals will be extended.

・Employs the same specifications and dimensions as the existing

model, C55 ISO Cylinder series.

・ISO Standards (21287)

Safety Instructions Actuators/Precautions Auto Switches/Precautions Model Selection/Technical Data Green Procurement (RoHS)

| Type | Series | Action | Bore size (mm) |

|---|---|---|---|

| Longer life | C55-XB24 | Double acting, Single rod | 20, 25, 32, 40 |

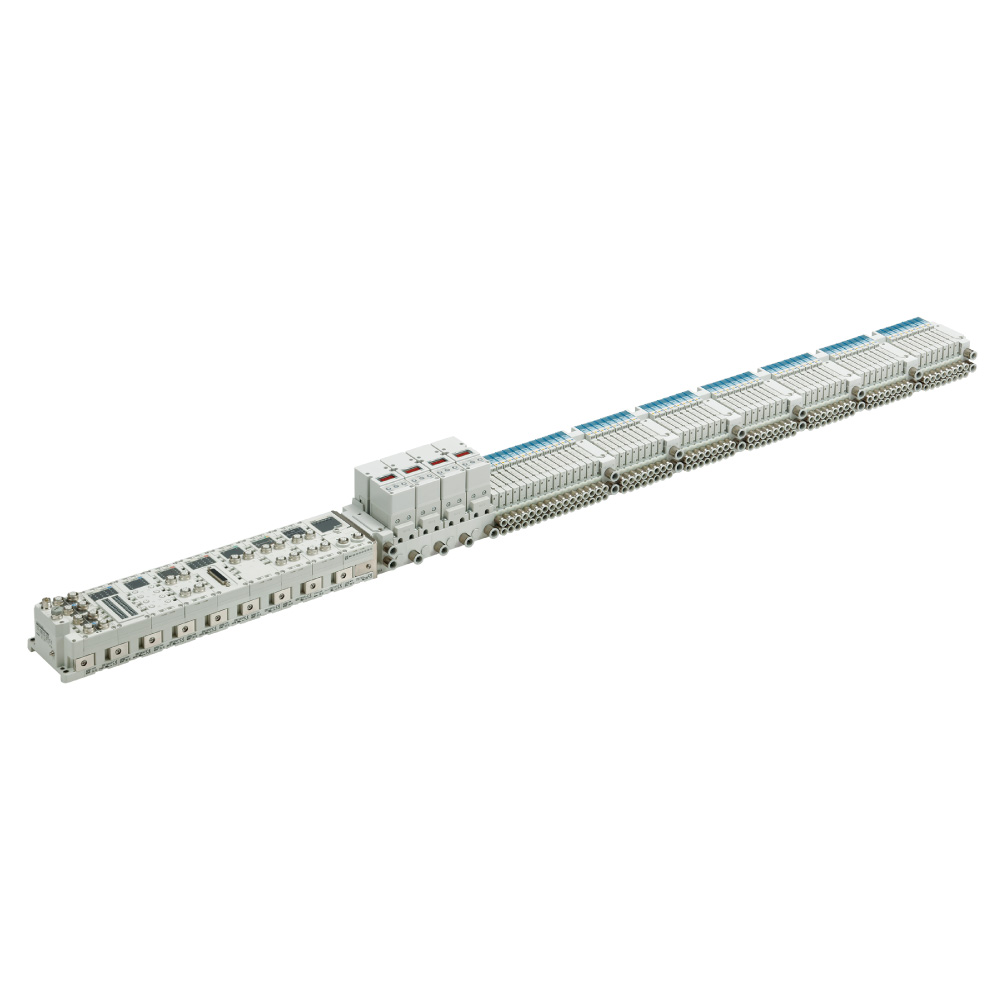

Electro-pneumatic Regulator Integrated Type 64-station Compatible Manifold Plug-in Compact 5-Port Solenoid Valve JSY3000-P

Directional Control Valves » Pilot Operated 4/5 Port Solenoid ValvesIndustrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: PROFINET Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherNet/IP Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherCAT Compatible Products

-

・Solenoid valves and electro-pneumatic regulators can be connected to

the same manifold.

Valve stations/Number of outputs: For 4 to 64 stations∗/128 points

∗ Stations are only available in multiples of 4.

Electro-pneumatic regulator stations: 1 to 4 stations

I/O unit stations: Max. 8 stations

・Equipment integration allows for the centralized management of control

and wiring as well as reduced wiring

Reduced wiring, Reduced number of SI units, Reduced wiring work,

Compact

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Enclosure | Communication protocol | Applicable devices |

|---|---|---|---|

| JSY3000-P | IP65 | PROFINET EtherNet/IP™ EtherCAT | SI unit: EX600 Valve: JSY3000 Electro-pneumatic regulator: ITV2340 |

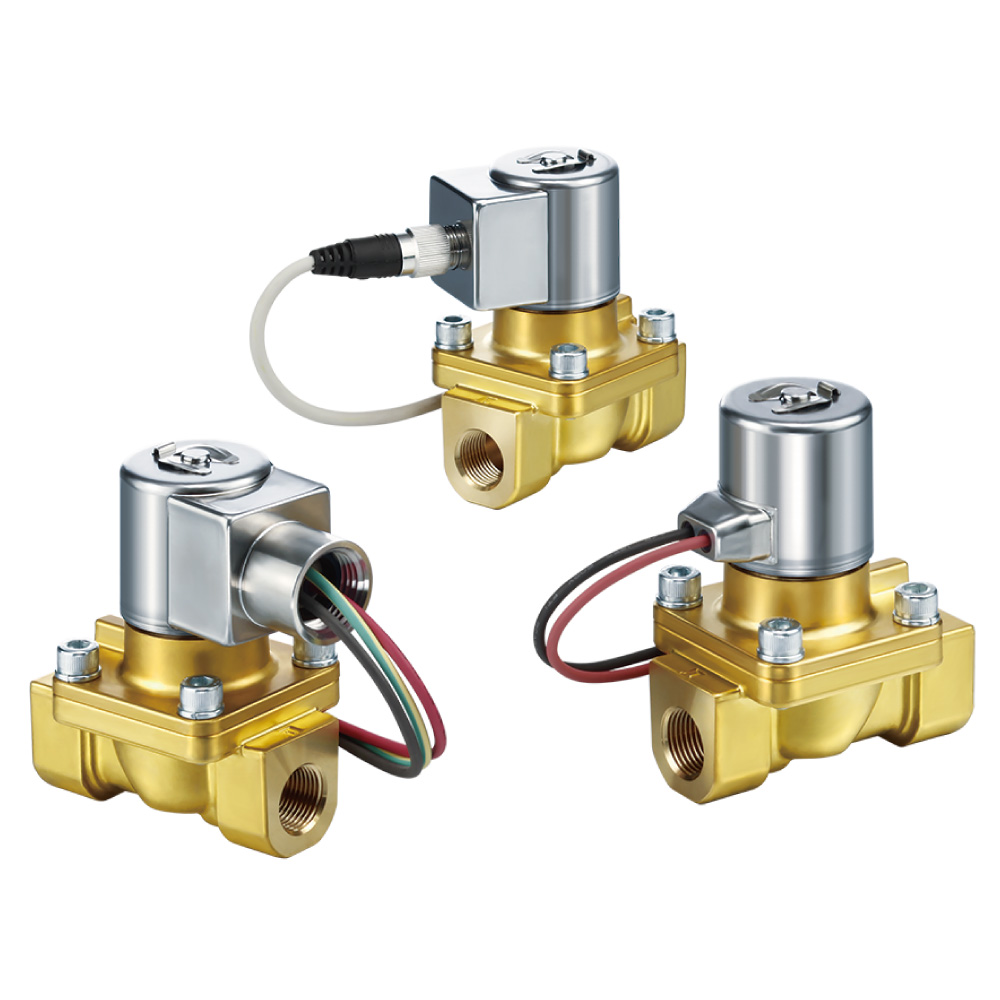

Pilot Operated 2-Port Solenoid Valve JSXH-X1

Process Valves » 2/3 Port Solenoid Valves/Air Operated Valves-

・Max. operating pressure differential: 4.0 MPa

Application examples: Blow molding, Laser processing machines,

Nitrogen filling unit

・Fluid: Compressed air, Nitrogen, Argon, Oxygen∗

∗ When using oxygen, please refer to "Fluid Supply."

・Improved environmental resistance

Dustproof/waterproof IP67 structure (IP65 for the DIN terminal)

With a stainless steel coil cover

・Low particle generation

・Oil-free

・Easy maintenance

The coil can be replaced by simply removing the clip.

・Power saving (Power consumption: 6 W)

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions Model Selection/Flow Rate Characteristics Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List Green Procurement (RoHS)

| Series | Type | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|---|

| JSXH-X1 | Pilot operated | N.C. | 3/8,1/2 | 16 |

Compact Cylinder / High Power Type CQE

Air Cylinders » Compact Air Cylinders-

・Theoretical output: Max. 1.5 times

・This is done even with the same external dimensions of the CQ2 series.

・The theoretical output of the next larger bore sized cylinder is made

possible with the polygonal piston shape.

・Contributes to a lower pressure air line, Supply pressure decreased by

0.17 MPa

The same theoretical output is available even when the supply pressure

to the cylinder is decreased.

Safety Instructions Actuators/Precautions Auto Switches/Precautions

Model Selection/Technical Data Green Procurement (RoHS)

Model Selection/Technical Data Green Procurement (RoHS)

| Type | Series | Action | Bore size [mm] |

|---|---|---|---|

| High power type | CQE | Double acting, Single rod | 20,25,32,40 |

Longer Life Cylinder C85/C75-XB24

Air Cylinders » ISO Cylinders: ISO Standards (6432)-

・New technology offers at least 4 times better durability.

・The maintenance intervals will be extended.

・Employs the same specification and dimensions as the existing models,

C85 ISO Cylinder series and C75 Air Cylinder series.

Safety Instructions Actuators/Precautions Auto Switches/Precautions Model Selection/Technical Data Green Procurement (RoHS)

| Type | Series | Action | Bore size (mm) |

|---|---|---|---|

| Longer life | C85-XB24 | Double acting Single rod | 8,10,12,16,20,25 |

| Longer life | C75-XB24 | Double acting Single rod | 32,40 |

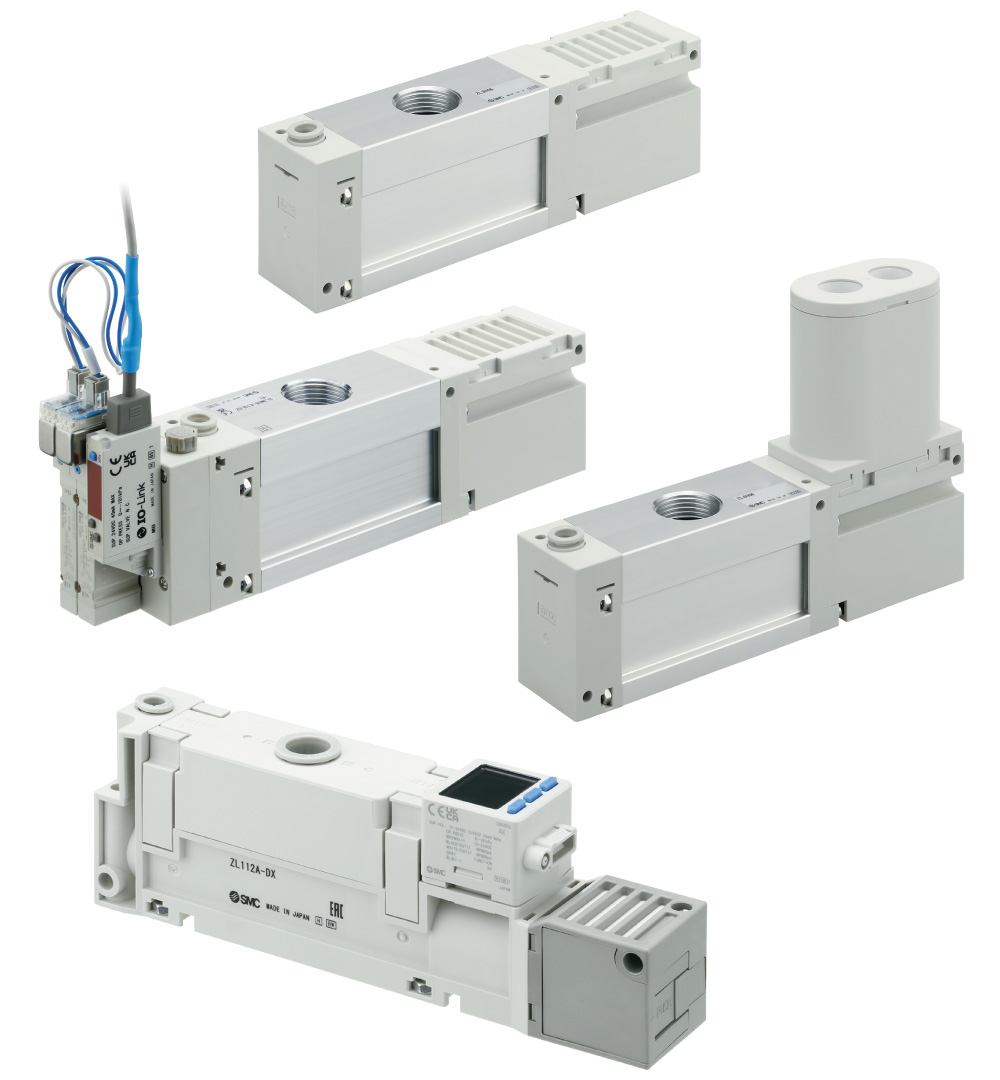

Multistage Ejector ZL1/ZL3/ZL6

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems-

・An IO-Link compatible vacuum pressure switch has been added. (ZL3,

ZL6) New

Allows for ejector control with a single communication line

Reading of the device information and parameter batch settings are

possible.

・Max. suction flow rate: 3 types available: 100, 300, and 600 L/min (ANR)

・Air consumption: 91% reduction (ZL3, ZL6)

Reduced by the pressure switch for vacuum with energy saving function

and efficient ejectors

・Weight: Max. 60% reduction [ZL112 (Existing model): 450 g → ZL1: 180 g]

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|

| ZL1 | 1.2 | 100 | 57 |

| ZL3M | 1.9 | 300※1 | 150 |

| ZL3H | 1.5 | 300※1 | 135 |

| ZL6M | 1.9×2 | 600※1 | 300 |

| ZL6H | 1.5×2 | 600※1 | 270 |

Electric Vacuum Gripper for Collaborative Robots ZXPE5

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Gripper for Collaborative RobotsElectric Actuators/Cylinders » Grippers for Collaborative Robots

Grippers for Collaborative Robots » Electric Vacuum Grippers (Built-in Vacuum Pump Type)

-

・A vacuum gripper that doesn't require an air source

・Operation possible by simply connecting an electrical wire connector

Can be used without an air source due to the built-in vacuum pump

・Unitization of the peripheral devices required for adsorption

The vacuum pump, atmospheric release valve, pressure monitor,

and cups have been integrated.

・Current consumption: Max. 64% reduction

Energy-saving operation possible via automatic/manual modes

・Lightweight: 556 g

・A wide variety of cup variations are available to support a wide range of

workpiece shapes.

・Standards: Conforming to ISO9409-1-50-4-M6

∗1 These are the values under SMC measurement conditions when the gripper is in continuous mode (the vacuum pump working continuously) and may vary depending on the

atmospheric pressure (weather, altitude, etc.) and the measurement method.

∗2 May be restricted depending on the cup diameter, mounting orientation, or workpiece. Please use within the max. work load. Suction and transfer exceeding the max. work load may result in product failure and the dropping of workpieces.

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Cup form | Cup diameter | Max. suction flow rate*1 [L/min(ANR)] | Max. work load*2

[Kg] |

|---|---|---|---|---|

| ZXPE5 | Flat Flat with rib Bellows Thin flat Multistage bellows 2.5-stage bellows 5.5-stage bellows Flat type for film packaging workpieces | φ8 to φ32 | 4.5 | 5 |