There were 245 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

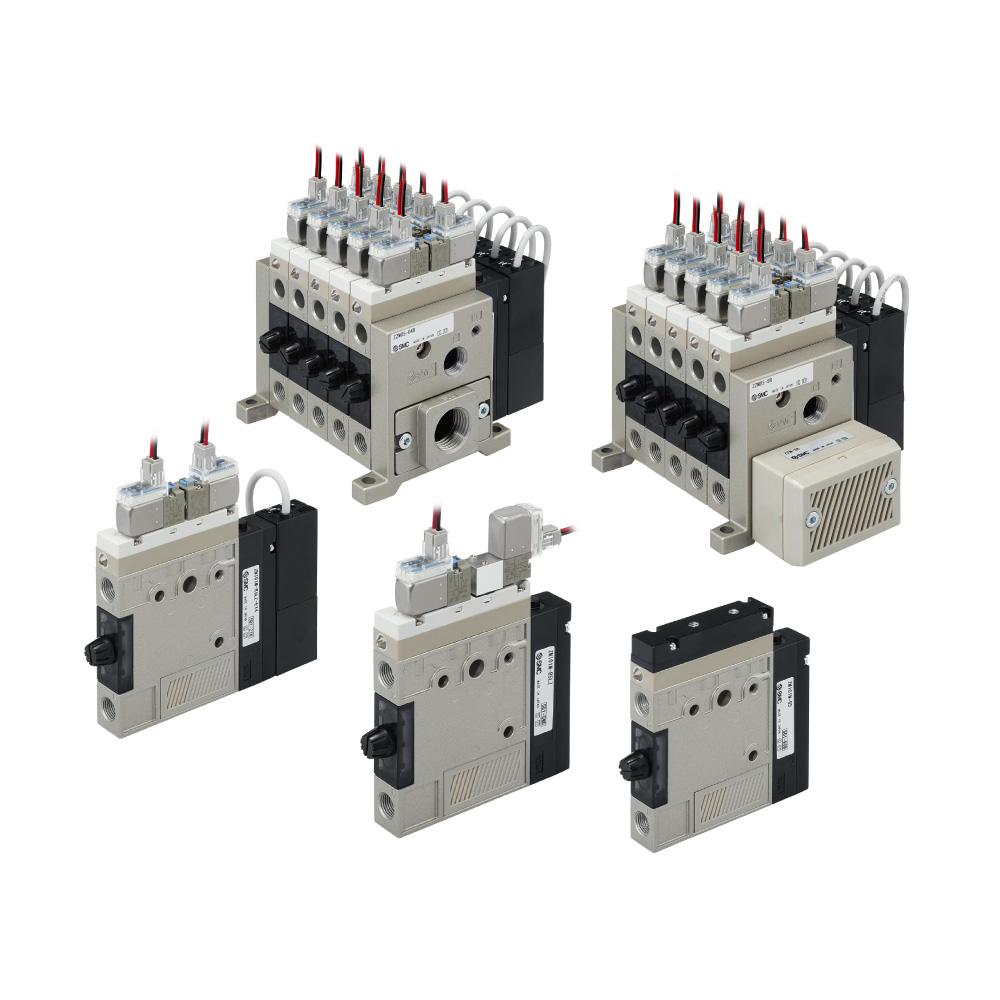

5-Port Solenoid Valve/Plug-in Type SY3000/5000/7000

Directional Control Valves » Pilot Operated 4/5 Port Solenoid Valves-

・Due to the flow increase, the valve size can be reduced!

Saves energy and space

・Power consumption: 0.1 W (With power saving circuit)/0.35 W (Standard)

・Plug-in sub-plate has been newly added!

・Plug-in metal base (IP40)/Plug-in connector connecting base (IP67)

・Manifold type no.: SS5Y3, SS5Y5, SS5Y7

・Can be connected to F.R.L. units (AC-D series) (-X990)

・Supports Interface regulators

*The EX250/500 series is to be discontinued. When designing new

equipment and facilities, consider using another series (EX260/EX600)

instead.

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions

Selection/Technical Data Quick Selection Table Green Procurement (RoHS)

Selection/Technical Data Quick Selection Table Green Procurement (RoHS)

| Series | Flow rate characteristics 4/2→5/3(A/B→EA/EB) C[dm3/(s・bar)] | Flow rate characteristics 4/2→5/3(A/B→EA/EB) b | Applicable cylinder size | Power consumption (W) |

|---|---|---|---|---|

| SY3000 | 1.6 | 0.19 | φ50 | 0.35(Standard) 0.1(With power saving circuit) |

| SY5000 | 3.6 | 0.17 | φ63 | 0.35(Standard) 0.1(With power saving circuit) |

| SY7000 | 5.9 | 0.20 | φ80 | 0.35(Standard) 0.1(With power saving circuit) |

Suction Cup/Compatible with Metal Detectors HF3A-ZP3F

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Pads (Vacuum Suction Cups)-

・Bellows type cup with excellent cushioning and flexibility

Reduces the deformation of soft workpieces such as bread

・The cups and retainers are made of materials compliant with the FDA

(U.S. Food and Drug Administration) dissolution test, EC directives,

and Japan Food Sanitation Act standards.

・Improved durability due to anti-stick grooves

・Equipment for the food manufacturing industry HF3A- series

| Series | Cup form | Cup diameter (mm) |

|---|---|---|

| HF3A-ZP3F | Bellows type (4.5-stage) | φ40 |

Magnetically Coupled Rodless Cylinder 12-CY3

Clean Series/Low-Particle Generation » Air Cylinders

Clean Series

・Further improvement on Series CY1

・Same mounting dimensions as those of Series CY1.

・Upgraded bearing performance and reduction of sliding resistance.

・NPT thread and G thread as standard

Safety Instructions Features/Basic Specifications/Clean Series Precautions

Actuators/Precautions Green Procurement (RoHS)

Actuators/Precautions Green Procurement (RoHS)

| Guide Type | Type | Series | Bore size (mm) |

|---|---|---|---|

| Guide non-integrated | Basic | 12-CY3B | 6, 10, 15, 20, 25, 32, 40, 50, 63 |

| Guide non-integrated | Direct mount | 12-CY3R | 6, 10, 15, 20, 25, 32, 40, 50, 63 |

Fixed Pipe Type Oil Cooler: Water Cooled, Iron Particle Type HOWF

Hydraulic Equipment » Hydraulic Equipment

-

・High heat transfer coefficient through the effects of turbulence

・Compact design requiring less installation space: 1/2 to 1/5 the size of existing oil

coolers

・Flexible installation orientation

・Minimal pressure drop

| Series | Heat transfer area (Inside pipe) m2 | Heat exchange volume (kW) | Flow rate L/min Oil side | Flow rate L/min Cooling water side |

|---|---|---|---|---|

| HOWF | 0.077 to 1.28 | 5.2 to 73 | 20 to 800 | 40 to 125 |

Compact Direct Operated 2/3-Port Solenoid Valve for Chemical Liquids LVM

Process Valves » Compact 2/3 Port Solenoid Valves-

・Low particle generation, Oil-free, Metal-free * Fluid contact parts

・Isolated structure

The solenoid drive body is separated from the fluid area by a diaphragm.

・Power consumption: 1.0 W or less (With power saving circuit)

・Change in volume (Pumping volume): 0.01 µL or less

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics Series Variations/Solenoid Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics Series Variations/Solenoid Valves List

Green Procurement (RoHS)

| Series | Valve construction | Valve type | Operating pressure range | Orifice diameter (mmø) |

|---|---|---|---|---|

| LVM07 Base mounted | Direct operated rocker type | N.C. | -75 kPa to 0.1 MPa | 0.8 |

| LVM09 Body ported Base mounted | Direct operated rocker type | N.C. N.O. Universal | -75 kPa to 0.2 MPa | 1 (Body ported) 1.1 (Base mounted) |

| LVM10 Body ported Base mounted | Direct operated rocker type | N.C. N.O. Universal | -75 kPa to 0.25 MPa | 1.4 |

| LVM15 Body ported Base mounted | Direct operated rocker type | N.C. N.O. Universal | -75 kPa to 0.25 MPa (Max. 0.6 MPa) | 1.6 1 (High-pressure type) |

| LVM20 Body ported Base mounted | Direct operated rocker type | N.C. N.O. Universal | -75 kPa to 0.3 MPa (Body ported: 0.25 MPa) | 2 |

| LVM1□ Body ported Base mounted | Direct operated poppet type | N.C. | 0 to 0.25 MPa | 1.5 |

| LVM3□ Body ported Base mounted | Direct operated poppet type | N.C. | -90 kPa to 0.2 MPa | 5 |

Flow Sensor PFMV5/PFGV301

Switches/Sensors/Controller » Electronic Flow Switches/Sensors-

・For suction verification of very small workpieces

・Repeatability: ± 2% F.S.

・Response speed: 5 ms or less, Withstand pressure: 500 kPa

・Grease-free, RoHS compliant

・Only 1 voltage monitor is required to cover the complete range.

・Related equipment: Suction filter ZFC050 series

Safety Instructions Pressure Switches/Flow Switches/Precautions Flow Switch Series Variations

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Rated flow range (L/min) |

|---|---|

| PFMV | 0.0 to 0.1 0 to 0.5 0 to 1 0 to 3 -0.5 to 0.5 -1 to 1 -3 to 3 |

S Couplers Stainless Steel Type KKA

Fittings and Tubing » Fittings for Special Environments

-

・Body material: Stainless steel 304

・Seal material: Fluoropolymer (Special FKM) is employed.

・Grease-free

・Check valve built in to both plug and socket

| Series | Connection thread |

|---|---|

| KKA | 1/8,1/4,3/8,1/2,3/4,1,1 1/4,1 1/2 |

Self-seal Fittings KC

Fittings and Tubing » Fittings for General Purposes

-

・One-touch installation and removal

・Built-in self-sealing mechanism

・Air does not exhaust after the removal of tubing.

・Copper-free (Electroless nickel-plated)

| Series | Applicable tubing O.D. | Connection thread |

|---|---|---|

| KC | φ4,φ6,φ8,φ10,φ12 | M5×0.8,1/8,1/4,3/8,1/2 |

Odor Removal Filter AMF

Air Preparation Equipment » Air Preparation Filters

-

・Efficiently removes odors in compressed air with an activated carbon element

This unit is designed for removing odors from places, such as clean rooms,

which must remain odorless

・Activated carbon element with large filtration area

・Easy element replacement and installation

Safety Instructions Air Preparation Equipment/Precautions Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) Element Part No.

| Series | Filtration (μm) | Air flow L/min (ANR) | Port size |

|---|---|---|---|

| AMF | 0.01 (Filtration efficiency: 99.9%) | 200 to 12000 | 1/8 to 2 |

Vacuum Ejector (Vacuum Generators) ZM

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems

-

・Valves and switches are unitized.

・Adaptable to manifold applications

・Maximum absorption flow rate has been increased by 40%.

・Max. vacuum pressure: −84 kPa

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) |

|---|---|---|---|---|

| ZM05 | 0.5 | 15 | 17 | 2 to 16 |

| ZM07 | 0.7 | 23 | 33 | 2 to 25 |

| ZM10 | 1.0 | 38 | 60 | 2 to 32 |

| ZM13 | 1.3 | 44 | 85 | 2 to 40 |

| ZM15 | 1.5 | 45 | 110 | 2 to 50 |