There were 245 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

M8/M12 Connector PCA/EX9/EX500

Directional Control Valves » Reduced-wiring Fieldbus System (Serial Transmission System)

-

・Communication cable/connector: CC-Link, DeviceNet™, PROFIBUS DP,

EtherNet/IP™, PROFINET, EtherCAT🄬, Ethernet POWERLINK

・Compliant with IEC61076-2-101 and IEC60947-5-2 Standards

・IP67 (IEC60529)

・Field-wireable connectors: No exclusive tools required, Reduction in wiring time

・SPEEDCON: Just insert the connector and make a 180° rotation.

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Fieldbus System Precautions

Industrial IoT Cybersecurity Glossary of Fieldbus Terms Series Variations/Applicable Valve Series

Green Procurement (RoHS)

Industrial IoT Cybersecurity Glossary of Fieldbus Terms Series Variations/Applicable Valve Series

Green Procurement (RoHS)

| Series |

|---|

| PCA |

| EX9 |

| EX500 |

Vertical Suction Filter for Coolant FHIAF-10-M149G

Industrial Filters/Sintered Metal Elements » Industrial Filters-

・Supports threaded connections

・Lightweight: 2.5 kg/Aluminum bodied

・Operating pressure: –100 to 0 kPa

・Nominal filtration: 149 μm (100 mesh)

・The vacuum pressure gauge can be used to manage clogging.

| Series | Port size | Operating pressure [kPa] | Nominal filtration [μm] |

|---|---|---|---|

| FHIAF-10-M149G | IN port : Rp3/4 OUT port : Rc1/2 | -100 to 0 | 149 (100 mesh) |

Direct Operated 2/3 Port Isolated Valve LVMK20/200

Process Valves » Compact 2/3 Port Solenoid Valves-

・Low particle generation, Oil-free, Metal-free

・Fluids: Air, Water, Deionized water, Diluent, Cleaning fluid

・Isolated structure: The solenoid drive body is separated from the fluid area by a block seal.

・Easy piping

・Minimal dead space

・Flow adjustment is not required.

| Series | Valve type | Piping direction | Fluid contact material |

|---|---|---|---|

| LVMK | N.C. Universal | Bottom ported Side ported | Body: PPS Seal: EPDM, FKM |

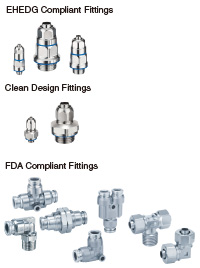

EHEDG Compliant/Clean Design/US FDA Compliant Fittings KFG2H□-E/KFG2H□-C/KQ□2-F・KFG2-F

Fittings and Tubing » Fittings for Special Environments-

・Hygienic design prevents liquid from accumulating after cleaning

・US FDA compliant materials

| Type | Series | Description | Thread type |

|---|---|---|---|

| EHEDG compliant | KFG2H□-E | Stainless steel 316 insert fittings | M,G |

| Clean design | KFG2H□-C | Stainless steel 316 insert fittings | M,G |

| FDA compliant | KQG2-F | Stainless steel 316 One-touch fittings | M,R,Rc, UNF,NPT G |

| FDA compliant | KQB2-F | Metal One-touch fittings | M,R,Rc, UNF,NPT G |

| FDA compliant | KFG2-F | Stainless steel 316 insert fittings | R,Rc, NPT G |

In-line Air Filter ZFD

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Air Suction Filters-

・Operating pressure range: −100 kPa to 0.5 MPa

・Able to capture foreign matter in both vacuum adsorption and vacuum

release directions, Prevents foreign matter from scattering again

・Space saving

Installation area: 41% reduction

・Check valve enclosure

Flow order: Filter➡Check valve

Prevents foreign matter from getting caught in the check valve

・Applicable tubing O.D.: ø4, ø6, ø8

| Series | Applicable tubing O.D. Metric | Operating pressure range [kPa] | Vacuum release pressure [MPa] | Weight [g] |

|---|---|---|---|---|

| ZFD53 | ø4 | −100 to 0 | 0.5 or less | 34 |

| ZFD54 | ø6 | −100 to 0 | 0.5 or less | 33 |

| ZFD55 | ø8 | −100 to 0 | 0.5 or less | 35 |

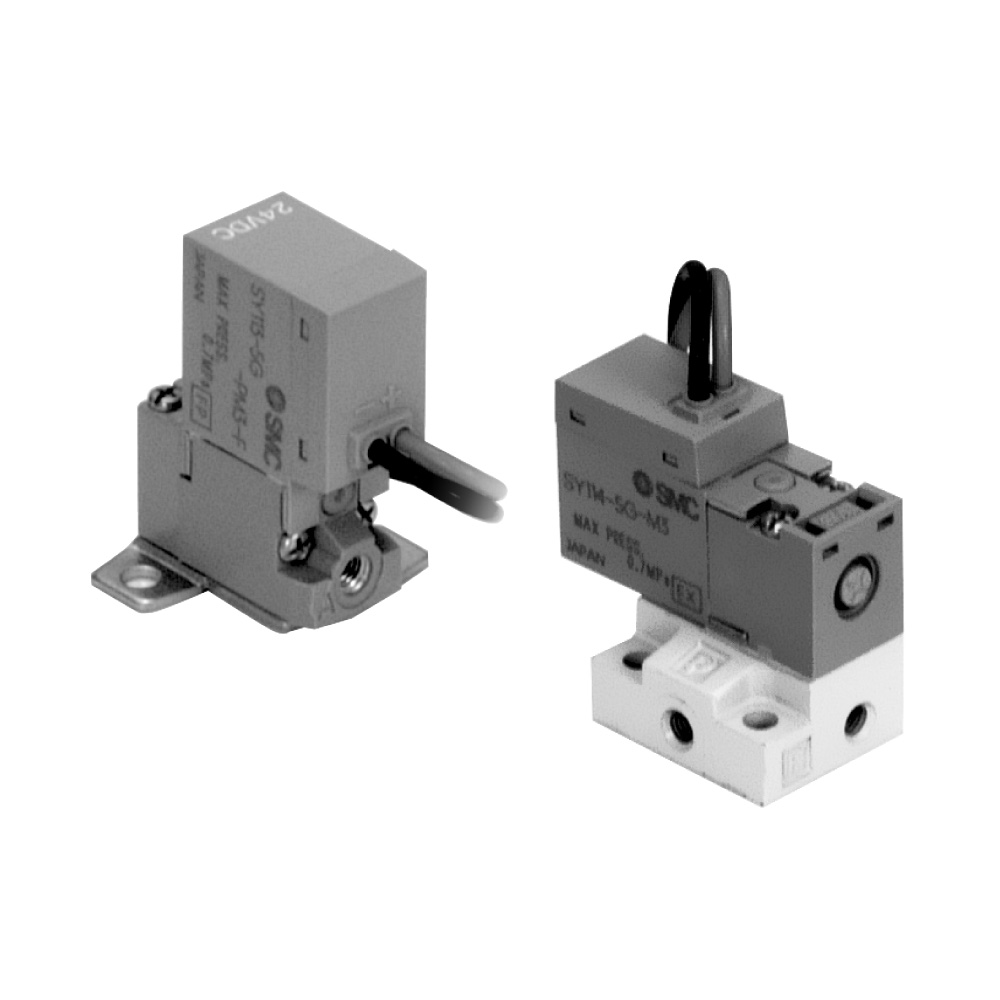

3 Port Solenoid Valve 10-SY

Clean Series/Low-Particle Generation » Directional Control Valves

Clean Series

★The value indicates the effective area (S).

Safety Instructions Features/Basic Specifications/Clean Series Precautions

3/4/5 Port Solenoid Valves/Precautions Green Procurement (RoHS)

3/4/5 Port Solenoid Valves/Precautions Green Procurement (RoHS)

| Series | Type | Sonic conductance: C | Power consumption (W) |

|---|---|---|---|

| 10-SY100 | Standard type | *0.14mm2 | 0.5 |

| 10-SY100 | Large flow type | *0.22mm2 | 0.5 |

One-touch Fitting with Improved Weather Resistance KQ-X1744

Fittings and Tubing » Fittings for Special Environments-

・Accelerated weathering test: Passed 1000 hours

ISO 4892-3 (JIS K 7350-3) compliant

・Combined cycle test: Passed 960 hours

ISO 14993 (JIS H 8502: 1999) compliant

・Ozone-proof exposure test: Passed 1000 hours

ISO 1431 (JIS K 6259) compliant

| Series | Applicable tubing O.D. | Connection thread |

|---|---|---|

| KQ-X1744 | φ4,φ6,φ8,φ10,φ12,φ16 | 1/8,1/4,3/8,1/2 |

Modular Connection Type Membrane Air Dryer IDG-D

Air Preparation Equipment » Air Dryers-

・Compatible with various ISO water quality classes

・Modular connection is possible.

・Non-fluorocarbon

・Power supply not required

・No vibration or heat discharge

・Contributes to energy saving

Pressure drop: Reduced by up to 61%

Outlet air flow rate: Max. 25% increase

Purge ratio: Approx. 14%

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Series | Standard inlet conditions | Outlet air flow rate L/min (ANR) | Pressure dew point (℃) | Water quality class | Applicable AC size | Port size |

|---|---|---|---|---|---|---|

| IDG20-D | 25℃, 0.7 MPa | 100 | 3 | 4 | AC20 | Rc, NPT, G 1/8, 1/4 |

| IDG30-D | 25℃,0.7 MPa | 250 | 3 | 4 | AC30 | Rc, NPT, G 1/4, 3/8 |

| IDG40-D | 25℃,0.7 MPa | 500 | 3 | 4 | AC40 | Rc, NPT, G 3/8, 1/2 |

Modular F.R.L. Units AC-A

Modular F.R.L./Pressure Control Equipment » Modular F.R.L.Modular F.R.L. Units » Modular F.R.L. Units/Air Combination

-

・Easy element replacement

The element and the bowl are integrated. Replacement can be done in

hand.

・Energy-saving regulator Pressure drop: Max. 50% improvement

・Reduced required maintenance space: Max. 46% reduction

・Better visibility&increased safety

The bowl is covered with a transparent bowl guard.

・Attachments:

Spacer: Y200-A, Y300-A, Y400-A, Y500-A

Spacer with bracket: Y200T-A, Y300T-A, Y400T-A, Y500T-A

∗ The AC20 to 60-A is to be discontinued as of March 2025.

Select the AC20 to 60-D as a substitute.▶Click here for details.

The AC10-A will continue to be produced, so it can be selected and used

as before.

| Combination equipment | Series | Port size | Set pressure (MPa) |

|---|---|---|---|

| Air filter, Regulator, Lubricator | AC10 to 40-A | M5,1/8,1/4,3/8,1/2,3/4 | 0.05 to 0.7 0.02 to 0.2 |

| Filter regulator, Lubricator | AC10A to 40A-A | M5,1/8,1/4,3/8,1/2,3/4 | 0.05 to 0.7 0.02 to 0.2 |

| Air filter, Regulator | AC10B to 40B-A | M5,1/8,1/4,3/8,1/2,3/4 | 0.05 to 0.7 0.02 to 0.2 |

| Air filter, Mist separator, Regulator | AC20C to 40C-A | 1/8,1/4,3/8,1/2,3/4 | 0.05 to 0.7 0.02 to 0.2 |

| Filter regulator, Mist separator | AC20D to 40D-A | 1/8,1/4,3/8,1/2,3/4 | 0.05 to 0.7 0.02 to 0.2 |

Controller/Step Data Input Type LECA6

Electric Actuators/Cylinders » Controllers/Drivers

-

・The controller is already set with the data of the actuator.

(The actuator and controller are provided as a set.)

・Easy operation and simple setting: Easy mode, Detail setting: Normal mode

・Teaching box, controller setting software

Safety Instructions Electric Actuators/Precautions Features

Series Variations Simplified Selection Flow Chart Wiring Method

Green Procurement (RoHS) CE/UL-compliance List

Series Variations Simplified Selection Flow Chart Wiring Method

Green Procurement (RoHS) CE/UL-compliance List

| Type | Series | Compatible motor | Power supply voltage | Parallel I/O Input | Parallel I/O Output | Number of step data |

|---|---|---|---|---|---|---|

| Step data input type | LECA6 | Servo motor (24 VDC) | 24 VDC ±10% | 11 (Photo-coupler isolation) | 13 (Photo-coupler isolation) | 64 points |