There were 709 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

FR One-touch Fittings KR-W2

Fittings and Tubing » Fittings for Special Environments

-

・For use where weld spatter is generated/Flame resistant

(Equivalent to UL-94 Standard V-0)

・Flame resistant spatter cover (KR-□C-X1807)

| Series | Applicable tubing O.D. | Connection thread |

|---|---|---|

| KR-W2 | φ6,φ8,φ10,φ12 | 1/8,1/4,3/8,1/2 |

One-touch Fittings KQ2

Fittings and Tubing » Fittings for General Purposes-

・Can be used in vacuum to –100 kPa

・Body types: Total of 51 models

・Thread material/Surface treatment (Treated or Non-treated): 2 types

・Selectable surface treatments: Brass (No plating), Electroless nickel-plated brass

・Applicable tubing O.D.

Round Type

Metric: ø2, ø3.2, ø4, ø6, ø8, ø10, ø12, ø16

Inch:ø1/8'', ø5/32'', ø3/16'', ø1/4'', ø5/16'', ø3/8'', ø1/2''

Oval Type

Metric: ø3.2, ø4, ø6

Inch:ø1/8'', ø5/32'', ø3/16''

・Connection thread

Metric:M3, M5, M6

R,Rc :1/8, 1/4, 3/8, 1/2

G:1/8, 1/4, 3/8, 1/2

NPT:10-32UNF, 1/16, 1/8, 1/4, 3/8, 1/2

Uni:1/8, 1/4, 3/8, 1/2

・Seal method

Sealant/Gasket seal

Face seal

Gasket seal(Uni thread)

| Series | Release button shape | Size | Connection thread |

|---|---|---|---|

| KQ2 | Oval Type | Metric, Inch | M,R,Rc,G,NPT,Uni |

| KQ2 | Round Type | Metric, Inch | M,R,Rc,G,NPT,Uni |

Modular F.R.L. Units AC-D

Modular F.R.L./Pressure Control Equipment » Modular F.R.L.Modular F.R.L. Units » Modular F.R.L. Units/Air Combination

-

・Modular design with uniform body style

・Better visibility & environmental resistance

・2-layer construction: The bowl is covered with a transparent bowl guard!

Better visibility: 360°

・No tools are required.

Easier replacement of the element (AF-D only)

・Attachments:

Spacer: Y200-D, Y300-D, Y400-D

Spacer with bracket: Y200T-D, Y300T-D, Y400T-D

Safety Instructions F.R.L. Units/Precautions Product Selection Guide

Green Procurement (RoHS) List of spacers for old and new modular connection and spacers with bracket

Green Procurement (RoHS) List of spacers for old and new modular connection and spacers with bracket

| Description | Series | Port size |

|---|---|---|

| Air filter, Regulator, Lubricator | AC20 to 60-D | 1/8,1/4,3/8,1/2,3/4,1 |

| Filter regulator, Lubricator | AC20A to 60A-D | 1/8,1/4,3/8,1/2,3/4,1 |

| Air filter, Regulator | AC20B to 60B-D | 1/8,1/4,3/8,1/2,3/4,1 |

| Air filter, Mist separator, Regulator | AC20C to 40C-D | 1/8,1/4,3/8,1/2 |

| Filter regulator, Mist separator | AC20D to 40D-D | 1/8,1/4,3/8,1/2 |

Auto Drain Valve AD402-A

Air Preparation Equipment » Auto Drains/Differential Pressure Gauges-

・Improved foreign matter resistance

・Increase in condensate discharge

Drain discharge: Max. 100 cm3/cycle (3 times that of the existing model)

・Improved environmental resistance: Transparent bowl guard can protect the inner

bowl

・Improved visibility: 360°

・Lightweight: Weight reduced by 22%

・Reduced required maintenance space

・Easier maintenance

One-touch mounting and removal of the bowl is possible without using any tools.

・Bowl material can be selected according to the operating environment.

| Series | Port size | Drain port size |

|---|---|---|

| AD402-A | 1/4, 3/8, 1/2 | 3/8 |

Clean Gas Filter SF

Air Preparation Equipment » Air Preparation FiltersClean Series/Low-Particle Generation » Clean Gas Filters/Air Filters

-

・Cartridge type allows for element replacement

(SFA100/200/300, SFB100)

・Compact, disposable type for the semiconductor industry

(SFB300, SFC100)

Safety Instructions Air Preparation Equipment/Precautions Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Type | Series | Operating pressure | Filtration (μm) |

|---|---|---|---|

| Cartridge type disc | SFA100/200/300 | Max. 0.99 MPa (Vacuum: 1.3×10-6 kPa) | 0.01 (Filtration efficiency: 99.99%) |

| Cartridge type straight | SFB100 | Max. 0.99 MPa (Vacuum: 1.3×10-6 kPa) | 0.01 (Filtration efficiency: 99.99%) |

| Cartridge type straight | SFB200 | Max. 0.99 MPa (Vacuum: 1.3×10-6 kPa) | 120 |

| Disposable type straight | SFB300 | Max. 0.99 MPa (Vacuum: 1.3×10-6 kPa) | 0.01 (Filtration efficiency: 99.99%) |

| Disposable type multiple disc | SFC100 | Max. 0.99 MPa (Vacuum: 1.3×10-6 kPa) | 0.01 (Filtration efficiency: 99.99%) |

Line Filter AFF

Mist Separator AM

Micro Mist Separator AMD

Micro Mist Separator with Pre-filter AMH

Activated Carbon Filter AMK

Air Preparation Equipment » Air Preparation Filters-

・Modular connection type

・Compressed air purity class: ISO 8573

・Face-to-face and depth dimensions reduced by 30%

・Weight reduced by 50%

AFF/AM□20: 0.19 kg (Existing model: 0.38 kg)

・Flow capacity increased by 50%

・No tools are required.

Easy replacement of the element

・Transparent bowl guard (2-layer construction)

・Color-identifiable elements

・With element service indicator

・With clogging switch/With element service indicator

Safety Instructions Air Preparation Equipment/Precautions Selection/Technical Data Green Procurement (RoHS) Element Part No.

| Type | Series | Filtration (μm) | Oil mist concentration on the outlet side | Air flow (L/min[ANR]) | Port size |

|---|---|---|---|---|---|

| Line filter | AFF | 1.0 (Filtration efficiency: 99%) | - | 300 to 3700 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

| Mist separator | AM | 0.1 (Filtration efficiency: 99%) | 1 (≈ 0.8 ppm) or less | 300 to 3700 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

| Micro mist separator | AMD | 0.01 (Filtration efficiency: 99.9%) | 0.1 (≈ 0.08 ppm) or less | 300 to 3700 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

| Micro Mist Separator with Pre-filter | AMH | 0.01 (Filtration efficiency: 99.9%) | 0.1 (≈ 0.08 ppm) or less | 750 to 1500 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

| Activated carbon filter | AMK | - | 0.003 (≈ 0.0025 ppm) or less | 300 to 3700 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

Adsorption Plate SP

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Related Equipment for Vacuum Systems

-

・Ideal for the adsorption and fixing in place of thin sheets, glass panels, and soft workpieces

Workpieces will not be deformed since they are adsorbed with multiple micro air vents on the adsorption surface.

・A high level of machining accuracy

・Strong adsorption force

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Shape | Adsorption surface size | Sintered metallic element particle dia. | Suction port |

|---|---|---|---|---|

| SP | Rectangular, Square | □50 x 50 mm, □100 x 100 mm, □150 x 150 mm □200 x 200 mm, □250 x 250 mm, □300 x 300 mm | φ0.3 (Sphere) | 1/8 |

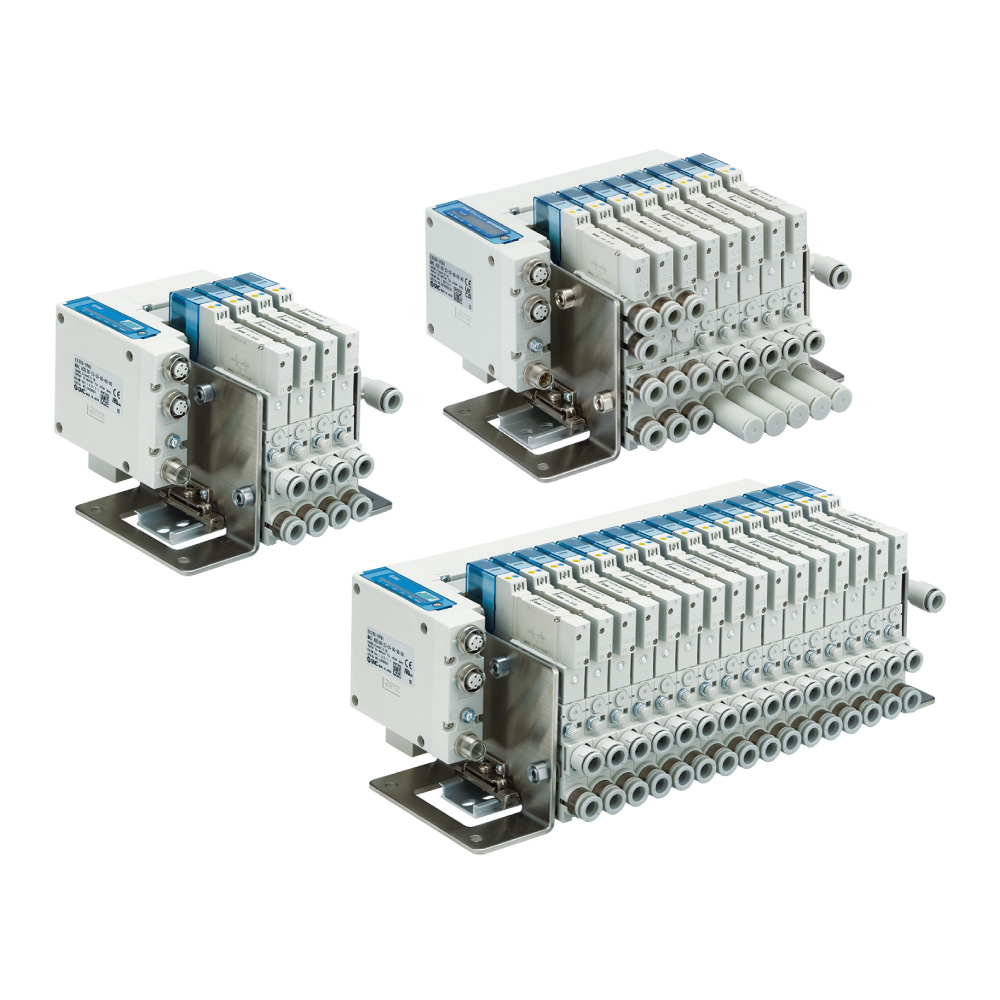

Vacuum Manifold for Fieldbus System ZKJ

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump SystemsIndustrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: PROFINET Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherNet/IP Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: IO-Link Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherCAT Compatible Products

IO-Link Devices » Vacuum Unit/Vacuum Manifold

-

・Vacuum pads and actuator driving can be controlled with a single

manifold [New]

・Positive pressure unit [New]

5-port solenoid valve

・Vacuum unit

Energy saving ejector Air consumption: 92% reduction

・Fieldbus compatible

Space saving: Requires no separate input/output units

Reduced wiring time

Compatible protocols: PROFINET, IO-Link, EtherNet/IP, EtherCAT

・Exhaust sealing function

Quick workpiece release

・4 stations/8 stations/12 stations/16 stations manifold compatible

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|

| ZKJ07 | 0.7 | 31 | 26 |

| ZKJ10 | 1.0 | 53 | 48 |

| ZKJ12 | 1.2 | 63 | 68 |

| ZKJ15 | 1.5 | 74 | 102 |

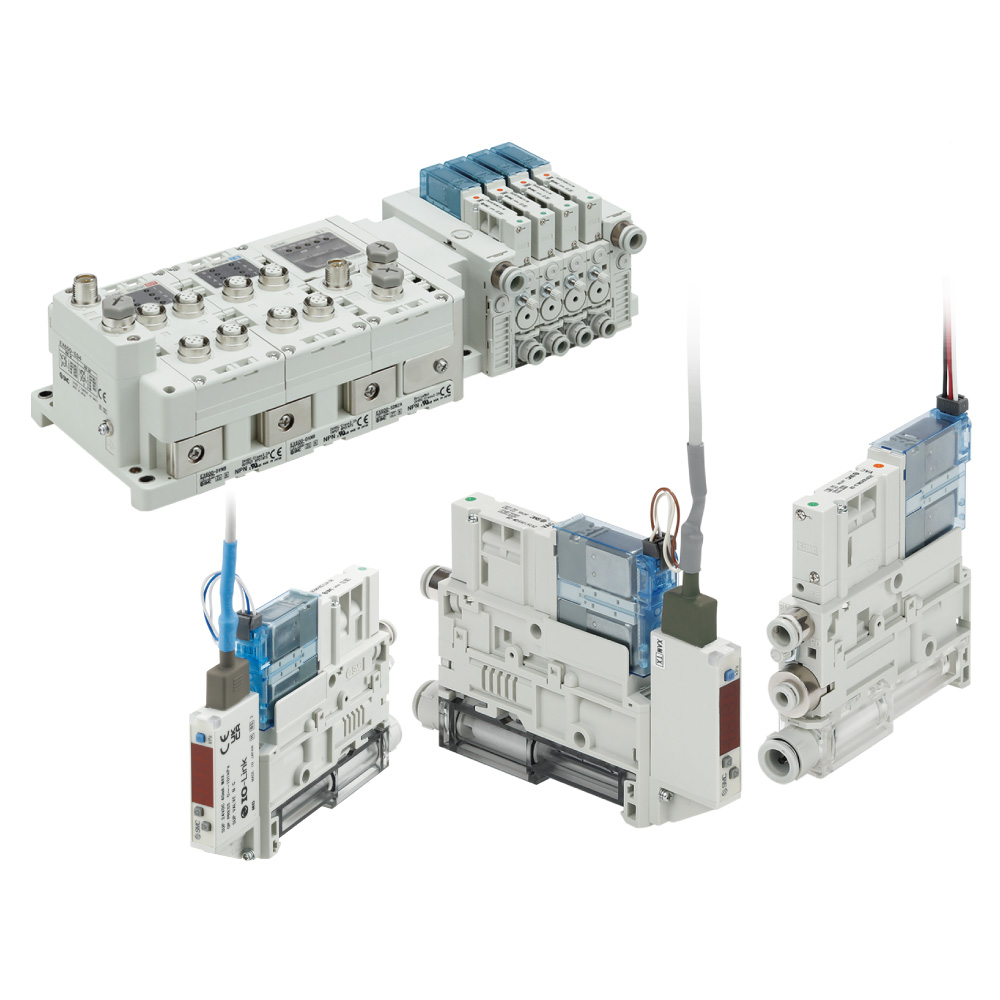

Vacuum Unit (Vacuum Generators) ZK2□A

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems-

・Supply valve: An N.O. specification has been added.

Can hold vacuum∗ even when the power goes out or is turned off

Prevents the sudden dropping of workpieces∗

∗ Supposing the supply pressure is being maintained

・An IO-Link compatible pressure switch has been added.

Allows for ejector control with a single communication line

Reading of the device information and parameter batch settings are

possible.

・Compatible with ejector systems and vacuum pump systems

・Energy saving ejector

Air supply is cut-off when vacuum is reached.

Air consumption: 93% reduction (Under SMC’s measurement conditions)

・More efficient ejector: Suction flow increased by 50% (Compared to other

SMC 1-stage ejectors)

・Energy saving efficiency: 93% reduction

・Improved low noise and suction flow by adoption of a high-noise

reduction silencer

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZK2□07 | 0.7 | 29 | 24 | 2 to 40 | ZK2□00 |

| ZK2□10 | 1.0 | 44 | 40 | 2 to 50 | ZK2□00 |

| ZK2□12 | 1.2 | 61 | 58 | 2 to 125 | ZK2□00 |

| ZK2□15 | 1.5 | 67 | 90 | 2 to 150 | ZK2□00 |

Electric Cylinder LZB/LDZB/LZC/LDZC

Electric Actuators/Cylinders » Electric Cylinders

-

・It can be operated like an air cylinder.

・With auto switch (LDZB series: LDZB, LDZC series: LDZC)

| Series | Max. thrust | Max. speed | Lead screw type | Stroke (mm) |

|---|---|---|---|---|

| LZB | 196 N or more | 200 mm/s or more | Slide screw : ø8, ø12 Lead : 2 mm, 6 mm, 12 mm | 25, 40, 50 100, 200 |

| LZC | 196 N or more | 200 mm/s or more | Slide screw : ø8, ø12 Lead : 2 mm, 6 mm, 12 mm | 25, 40, 50 100, 200 |