There were 1,276 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Clean One-touch Fittings for Blowing KP

Fittings and Tubing » Fittings for Special Environments(Clean/Fluoropolymer)Clean Series/Low-Particle Generation » Fittings

-

・One-touch fittings for clean room blowing systems

・Completely oil-free (Fluoro-coated rubber portions)

・Wetted parts are non-metallic.

・Parts washed and assembled in a clean room, Packed in double packaging.

・Can be used in a vacuum (−100 kPa)

| Series | Applicable tubing O.D. | Connection thread |

|---|---|---|

| KP | φ4,φ6,φ8,φ10,φ12 | 1/8,1/4,3/8,1/2 |

Stainless Steel 316 Insert Fittings KFG2

Fittings and Tubing » Fittings for Special Environments

-

・Compact and lightweight

・Fluid temperature: −65 to 260℃ (Swivel elbow: −5 to 150℃)

・Material: Stainless steel 316

Rubber materials are not used. (Excluding the swivel elbow)

・Grease-free/Can be used with steam

Certified to meet current Food Sanitation Law standards

| Series | Size | Tubing O.D. x I.D. | Connection thread |

|---|---|---|---|

| KFG2 | Metric | φ4 x φ2.5, φ4 x φ3, φ6 x φ4, φ8 x φ6, φ10 x φ7.5 φ10 x φ8, φ12 x φ9, φ12 x φ10, φ16 x φ13 | R,Rc 1/8,1/4,3/8,1/2 |

| KFG2 | Inch | φ1/8'' x φ0.086'',φ5/32'' x 0.098'',φ1/4'' x φ5/32'' φ5/16'' x 0.236'',φ3/8'' x φ1/4'',φ1/2'' x φ3/8'' | NPT1/8,1/4,3/8,1/2 |

Miniature Fittings M

Fittings and Tubing » Fittings for General Purposes

-

・Compact and doesn't require tools for connection

・Compact piping space

・Hose nipple, Hose elbow, Barb

| Series | Applicable tubing O.D. | Connection thread |

|---|---|---|

| M-□□-2 | φ2 | M3,M5 |

| M | φ3.2,φ4,φ6 | M3,M5,1/8 |

Liquid Collector/Exhaust Pressure Type AEP100

Lubrication Equipment » Lubrication Equipment

-

・Collect and reuse the leaked lubricating oil or hydraulic fluid using exhaust pressure.

・Collect the liquids using only the exhausted air released from the switching valve, Realizes energy saving

・Efficient operation that eliminates the need for collection and wiping by hand.

Compact Regulator ARX

Modular F.R.L./Pressure Control Equipment » RegulatorsPressure Control Equipment » Regulators

-

・Compatible with inlet supply pressures of 2.0 MPa

・Ideal for discharge pressure adjustment on small compressors

・Piston type

・Ideal for the pressure adjustment of air blowing applications

Safety Instructions F.R.L. Units/Precautions Series Variations/Pressure Control Equipment

Product Selection Guide Green Procurement (RoHS)

Product Selection Guide Green Procurement (RoHS)

| Series | Port size | Set pressure (MPa) |

|---|---|---|

| ARX20 | 1/4,1/8 | 0.05 to 0.85 |

Modular Type Common Supply Regulator AR□M(K)-D

Modular F.R.L./Pressure Control Equipment » Modular F.R.L.Modular F.R.L. Units » Regulators

-

・Supply different pressure for multiple applications

OUT port is on the back of the product.

・Space-saving design and reduced piping labor

・Modular connection is possible.

・Branch piping

| Series | Port size | Set pressure (MPa) |

|---|---|---|

| AR20M-D to AR40M-D | 1/8,1/4,3/8,1/2 | 0.05 to 0.85 0.02 to 0.2 |

| AR20MK-D to AR40MK-D With backflow function | 1/8,1/4,3/8,1/2 | 0.1 to 0.85 0.1 to 0.2 |

Micro Mist Separator with Pre-filter AMH

Air Preparation Equipment » Air Preparation Filters

-

・The integration of the AM series and AMD series achieves a reduction in

installation space and reduced piping installation labor and costs.

・Can separate and remove aerosol state oil mist and remove carbon or

dust of 0.01 μm or larger

・Should be used as a pre-filter for compressed air for precision instruments

or clean rooms requiring high levels of clean air

Safety Instructions Air Preparation Equipment/Precautions Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) Element Part No.

| Series | Filtration (μm) | Air flow L/min (ANR) | Port size |

|---|---|---|---|

| AMH | 0.01 (Filtration efficiency: 99.9%) | 200 to 12000 | 1/8 to 2 |

Magnet Gripper MHM-X6400

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Special PadsArc Welding Process Equipment » Specialty Cylinders

Rotary Actuators/Air Grippers » Magnet Grippers

-

・Steel plates can be transferred without a vacuum.

Can support workpieces with holes and uneven surfaces when a vacuum pad cannot be used

・Holds workpieces even when the air is shut off

・High holding force: 80 N (Workpiece plate thickness: 0.6 mm), 120 N

(Workpiece plate thickness: 1.4 mm)

・Residual holding force: 0.3 N or less (Reduces workpiece release time)

| Series | Holding force (Workpiece plate thickness: 0.6 mm) |

|---|---|

| MHM-32D1-X6400 | 80 N |

| MHM-32D2-X6400 | 50 N |

| MHM-32D3-X6400 | 30 N |

Compact Vacuum Ejector (Vacuum Generators) ZA

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems

-

・Total width: 9.9 mm, Total length: 72.9 mm, Total height: 52.5 mm,

Weight: 50 g

・Can be installed on moving parts

・Improved response through the shortening of the length of the tube to the pad

・Adaptable to manifold applications

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) |

|---|---|---|---|---|

| ZA105 | 0.5 | 4 | 12 | 2 to 13 |

| ZA107 | 0.7 | 8 | 28 | 2 to 20 |

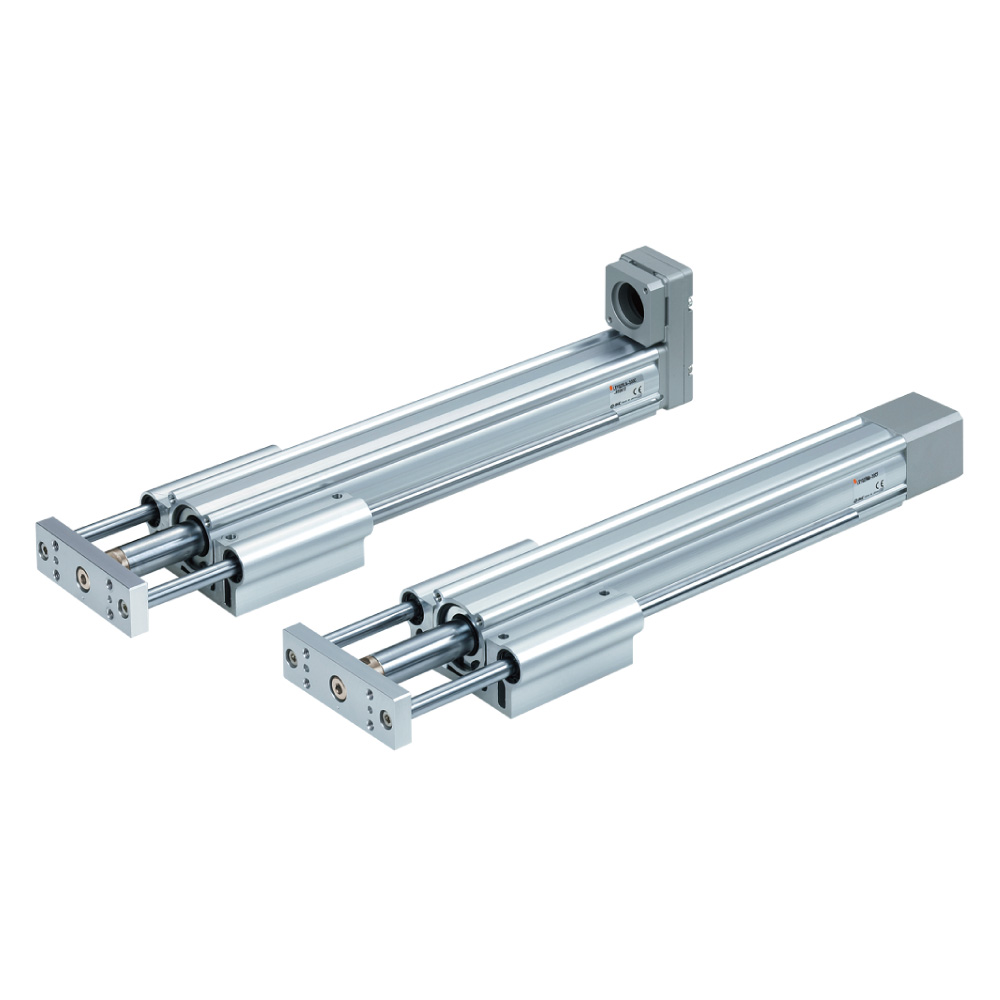

Electric Actuator/Guide Rod Type LEYG

Electric Actuators/Cylinders » Motorless Type-

・Various servo motors can be mounted due to the addition of the motorless type.

・Compatible motors:

Mitsubishi Electric Corporation, YASKAWA Electric Corporation,

SANYO DENKI CO., LTD., OMRON Corporation, Panasonic Corporation,

FANUC CORPORATION, NIDEC INSTRUMENTS,

KEYENCE CORPORATION, FUJI ELECTRIC CO., LTD., MinebeaMitsumi Inc.,

Shinano Kenshi Co., Ltd., ORIENTAL MOTOR Co., Ltd., FASTECH Co., Ltd.,

Rockwell Automation, Inc. (Allen-Bradley), Beckhoff Automation GmbH,

Siemens AG, Delta Electronics, Inc., ANCA Motion

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

| Specification | Model | Stroke (mm) | Pushing force (N) | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Motorless Top mounting | LEYG25 | 30 to 300 | Max. 485 | Max. 900 | 3, 6, 12 |

| Motorless In-line | LEYG25D | 30 to 300 | Max. 485 | Max. 900 | 3, 6, 12 |

| Motorless Top mounting | LEYG32 | 30 to 300 | Max. 588 | Max. 1200 | 4, 8, 16 |

| Motorless In-line | LEYG32D | 30 to 300 | Max. 736 | Max. 1000 | 4, 8, 16 |