There were 1,109 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

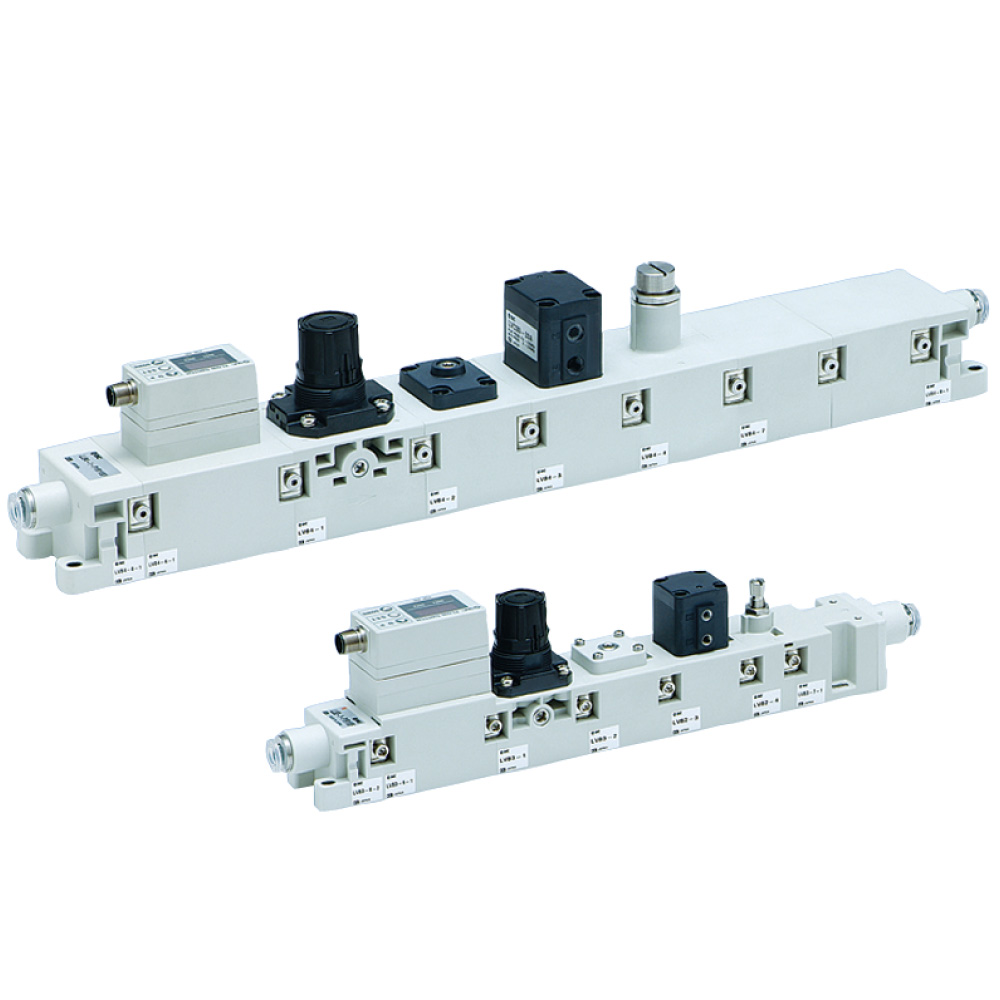

Clean Air Module LLB

Air Preparation Equipment » Air Preparation FiltersClean Series/Low-Particle Generation » Compressed Air Cleaning Filter Series

Clean Series/Low-Particle Generation » Clean Gas Filters/Air Filters

-

・Modularized clean equipment (Reduced piping labor/Space saving)

Makes clean air easily available

・Nominal filtration rating: 0.01 μm (Filtration efficiency: 99.99%)

・Wetted parts: Grease-free, Silicone-free

・Assembled in a clean room, Shipped and packed in double packaging

・24 combinations are available.

Note) Inlet air conditions ISO 8573-1 Quality grade: Equivalent to 1.4.1 to 1.6.1

Safety Instructions Air Preparation Equipment/Precautions Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Series | Fluid | Set pressure | Flow range L/min (ANR) |

|---|---|---|---|

| LLB3 | Clean air N2 gas Note) | 0.05 to 0.4 MPa | 5 to 100 |

| LLB4 | Clean air N2 gas Note) | 0.05 to 0.4 MPa | 50 to 500 |

Water Separator AMG

Air Preparation Equipment » Air Preparation Filters

-

・Compressed air without water can be obtained.

・Water drop removal ratio: 99%

・Easily connects to the air line to remove moisture!

Safety Instructions Air Preparation Equipment/Precautions Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) Element Part No.

| Series | Air flow capacity L/min (ANR) | Port size |

|---|---|---|

| AMG | 300 to 12000 | 1/8 to 2 |

Refrigerated Air Dryer IDU □E

Air Preparation Equipment » Air Dryers

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) Proposal for the Use of a Separate Refrigerated Air Dryer

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) Proposal for the Use of a Separate Refrigerated Air Dryer

| Series | Rated inlet condition | Air flow capacity (m3/min[ANR]) 50 Hz | Air flow capacity (m3/min[ANR]) 60 Hz | Applicable air compressor (kW) | Refrigerant | Port size | Compressor output |

|---|---|---|---|---|---|---|---|

| IDU3E | 55℃ 0.7 MPa | 0.32 | 0.37 | 2.2 | R134a (HFC) | Rc3/8 | Less than 7.5kw |

| IDU4E | 55℃ 0.7 MPa | 0.52 | 0.57 | 3.7 | R134a (HFC) | Rc1/2 | Less than 7.5kw |

| IDU6E | 55℃ 0.7 MPa | 0.75 | 0.82 | 5.5 | R134a (HFC) | Rc3/4 | Less than 7.5kw |

| IDU8E | 55℃ 0.7 MPa | 1.1 | 1.2 | 7.5 | R134a (HFC) | Rc3/4 | Less than 7.5kw |

| IDU11E | 55℃ 0.7 MPa | 1.5 | 1.7 | 11 | R134a (HFC) | Rc3/4 | Less than 7.5kw |

| IDU15E1 | 55℃ 0.7 MPa | 2.6 | 2.8 | 15 | R134a (HFC) | Rc1 | Less than 7.5kw |

| IDU22E | 55℃ 0.7 MPa | 3.9 | 4.3 | 22 | R407C (HFC) | R1 | Less than 7.5kw |

| IDU37E | 55℃ 0.7 MPa | 5.7 | 6.1 | 37 | R407C (HFC) | R1 1/2 | Less than 7.5kw |

| IDU55E | 55℃ 0.7 MPa | 8.4 | 9.8 | 55 | R407C (HFC) | R2 | Less than 7.5kw |

| IDU75E | 55℃ 0.7 MPa | 11.0 | 12.5 | 75 | R407C (HFC) | R2 | Less than 7.5kw |

Air Tank AT

Air Preparation Equipment » Aftercoolers/Air Tanks

-

・This air tank accumulates the compressed air from compressors,

prevents it from being pulsated, and cools it.

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Series | Port size | Tank capacity (L) |

|---|---|---|

| AT | 1/2 to 4B flange | 100 to 3000 |

Vacuum Flow ZH-X226/-X249/-X338

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum FlowAir Blowing Equipment » Air Blowing Equipment

-

・By supplying compressed air, large blow and vacuum flow rates are available.

Blow: Max. 1550 L/min (ANR)

Vacuum: Max. 880 L/min (ANR)

・Application examples

Adsorption transfer, coolant blow to blow off cutting chips, adsorption transfer

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Suction flow [L/min(ANR)] | Discharge flow [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|

| ZH-X226 | 405 | 700 | 297 |

| ZH-X338 | 880 | 1,550 | 570 |

| ZH-X249 | 820 | 1,160 | 340 |

Vacuum Gripper for Collaborative Robots ZXP7□-X1□-ASSISTA

for Mitsubishi Electric Corporation MELFA ASSISTA

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Gripper for Collaborative RobotsAir Gripper for Collaborative Robots » Vacuum Grippers

-

・Operate by simply connecting 1 compressed air supply tube and an electrical wiring M12 connector.

・Integrated vacuum ejector, air supply valve, pressure switch, and cups

・Features a rounded appearance without corners

・A wide variety of cup variations are available to support a wide range of workpieces.

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Cup form | Cup diameter | Suction flow rate [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|---|

| ZXP7□-X1□-ASSISTA | Flat Flat with rib Bellows Thin flat Multistage bellows 2.5-stage bellows 5.5-stage bellows | φ8 to φ32 | 17 | 57 |

Non-contact Gripper XT661

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Special PadsEquipment for the Semiconductor Industries » Slit Valve/Transfer

-

・Assists in non-contact workpiece transfer

・Max. workpiece suction distance: 10 mm

・2 types are available:

Cyclone type: High lift: Max. 44 N

Bernoulli type: Amplitude of the workpiece during gripping: ±0.01 mm or less

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

Oval Vacuum Pad (Vacuum Suction Cup) ZP/ZP2

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Pads (Vacuum Suction Cups)

-

・For rectangular, vertically long, and horizontally long workpieces

・Pad form: Oval flat type

・Mounting: Male thread, Female thread

・Vacuum inlet direction: Vertical, Lateral

・Vacuum inlet: Male thread, Female thread, One-touch fitting, Barb fitting

・Buffer: Without, With

Buffer stroke (mm): [ZP] 6, 10, 15, 20, 25

Buffer stroke (mm): [ZP2] 10, 20, 30, 40, 50

Safety Instructions Vacuum Equipment/Precautions Vacuum Pads/Precautions Series Variations Model Selection ZP: Mounting Bracket Assembly (p.189-194) ZP2: Mounting Bracket Assembly (p.195-197) Green Procurement (RoHS)

| Series | Pad form | Pad diameter(mm) |

|---|---|---|

| ZP | Oval flat type | 2×4, 3.5×7, 4×10 |

| ZP2 | Oval flat type | 3.5×7, 4×10, 4×20, 4×30, 5×10, 5×20, 5×30, 6×10, 6×20, 6×30, 8×20, 8×30 |

Vacuum Filter AFJ

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Related Equipment for Vacuum SystemsVacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Air Suction Filters

-

・Prevents problems with vacuum equipment!

・Nominal filtration rating: 5, 40, 80 μm

・Large flow capacity: Max. 660 L/min (ANR)

・Elements can be reused by washing them.

・Water droplets can be removed.

・The bowl is covered with a transparent bowl guard.

| Series | Port size | Recommended flow rate L/min (ANR) | Filtration |

|---|---|---|---|

| AFJ | 1/8,1/4,3/8,1/2 | 180,380,660 | 5,40,80 |

In-line Type Vacuum Ejector ZU□A

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors-

・Compact and Lightweight

O.D.: ø10.4, Weight: 3.9 g, Overall length: 52 mm

・Port size

ø4, ø6 One-touch fitting, Rc1/8 female thread, ø5/32″

・Vacuum pressure reached [kPa]

Type S: -90, -87, -85

Type L: -48, -40

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] Type S | Max. suction flow [L/min(ANR)] Type L | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) |

|---|---|---|---|---|---|

| ZU03□A | 0.3 | 1.8 | 3.4 | 4.2 | 2 to 8 |

| ZU04□A | 0.4 | 3.2 | 5.8 | 7.7 | 2 to 10 |

| ZU05□A | 0.5 | 7 | 13 | 14 | 2 to 13 |

| ZU07□A | 0.7 | 11 | 16 | 28 | 2 to 20 |