There were 1,109 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Thermo-chiller/Inverter Type HRSH090

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

Equipment for the Semiconductor Industries (Temperature Adjustment Line) » Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

Temperature Adjustment Line » Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

-

・Power consumption reduced by 53%

Complete with energy-saving triple inverter!

・Cooling capacity: 9.5 kW (Air-cooled), 11.0 kW (Water-cooled)

・Temperature stability: ±0.1°C

・Set temperature range: 5°C to 40°C

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRSH090 | 5 to 40℃ | 9.5 kW | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water Deionized water Ethylene glycol aqueous solution (15%) |

Thermo-chiller/Standard Type HRS

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

Temperature Adjustment Line » Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

Equipment for the Semiconductor Industries (Temperature Adjustment Line) » Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

-

・With this chiller, cooling water can be obtained anywhere it is necessary because of easy installation and easy operation.

・For a wide range of applications, such as laser machine tools, analytical equipment,

LCD manufacturing equipment, mold temperature control, etc.

・Compact: W 377 x H 615 x D 500 mm, 40 kg (HRS012/018/024)

・Timer function, Low liquid level protection, Power failure auto-restart,

Anti-freezing function, etc.

・Self diagnosis function

・Ideal for overseas models (Single-phase 200 to 230 VAC, Single-phase 100, 115 VAC)

・Compliant with UL Standards, CE-marking

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRS012 to 060 | 5 to 40℃ | 1.3 kW 1.9 kW 2.4 kW 3.2 kW 4.2 kW 5.1 kW 5.9 kW (60 Hz) | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water Deionized water Ethylene glycol aqueous solution (15%) |

Process Pump/Single Acting Pump PB

Process Pumps(Diaphragm Pumps) » Process PumpsFluoropolymer Equipment/PVC Equipment » Fluoropolymer Process Pumps

Safety Instructions Series Variations Related Products Applicable Fluids Product Specific Precautions Green Procurement (RoHS)

| Series | Actuation | Discharge rate (mL/min) | Wetted parts material |

|---|---|---|---|

| PB1011A | Built-in solenoid valve | 8 to 2000 | Polypropylene Stainless Steel 316 |

| PB1013A | Air operated type | 8 to 1000 | Polypropylene Stainless Steel 316 |

| PB1313A | Air operated type | 8 to 1000 | New PFA (Fluororesin) |

Process Pump/Double Acting Pump PA/PAX

Process Pumps(Diaphragm Pumps) » Process Pumps

Safety Instructions Series Variations Related Products Applicable Fluids Product Specific Precautions Green Procurement (RoHS)

| Series | Actuation | Discharge rate (L/min) | Wetted parts material |

|---|---|---|---|

| PA3□□0 | Automatically operated type | 1 to 20 | ADC12 (Aluminum) SCS14 (Stainless steel) |

| PA3□13 | Air operated type | 0.1 to 12 | ADC12 (Aluminum) SCS14 (Stainless steel) |

| PAX1□12 | Automatically operated type Built-in pulsation attenuator | 0.5 to 10 | ADC12 (Aluminum) SCS14(Stainless steel) |

Valve for Water and Chemical Base Fluids (2/3-Port Air Operated Valve) VCC

Process Valves » Valves for Water and Chemical Base Fluids

-

・Applicable for 2 liquid paints (VCC12D)

PTFE diaphragm structure = Elimination of sliding parts

Less paint adhesion

・Mountable on a robot arm (Space saving, Lightweight)

2 valves per station (30 mm pitch)

2/3-port valves mixed mounting

Resin manifold block

| Series | Orifice diameter | Fluid |

|---|---|---|

| VCC | φ3.8 | Water/chemical-based paint, Ink, Cleaning fluid (Water, Butyl acetate), Air |

Coolant Valve (2 Way Valve)/Low Power Consumption, High Flow Type SGC

Process Valves » Coolant Valves-

・High flow type to control coolants (Cutting fluid) in machine tools

・Low power consumption: 0.35 W (at 24 VDC)

・Maximum operating pressure: 0.5 MPa, 1 MPa, 1.6 MPa

・Service life: 5 million cycles or more (Based on SMC's test conditions)

・CE-compliant

・Compatible with G threads (ISO1179-1) as standard

・Air operated, external pilot solenoid

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics Series Variations/Process, Coolant Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics Series Variations/Process, Coolant Valves List

Green Procurement (RoHS)

| Series | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|

| SGC | N.C./N.O. | 3/8 to 2 | 9 to 51 |

Process Valve/2 Port Valve (2 Way Valve) for Compressed Air and Air-hydro Circuit Control VNA

Process Valves » 2/3 Port Valves for General Purpose Fluid Control

-

・Exclusively for pneumatic systems and air-hydro circuit controls

・The balance poppet permits normal and reverse flow.

・Air operated, external pilot solenoid

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics Series Variations/Process, Coolant Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics Series Variations/Process, Coolant Valves List

Green Procurement (RoHS)

| Series | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|

| VNA | N.C./N.O./C.O. | 1/8 to 2 | 10 to 50 |

5.0 MPa Pilot Operated 2/3-Port Solenoid Valve & Check Valve VCH/VCHC

Process Valves » 5.0 MPa 2/3 Port Solenoid Valves

-

・Service life: 10 million cycles

・Uses a polyurethane elastomer poppet for valve parts

・Improves durability at high pressures

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics Series Variations/Solenoid Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics Series Variations/Solenoid Valves List

Green Procurement (RoHS)

| Series | Type | Port size | Orifice diameter (mmø) |

|---|---|---|---|

| VCH41 | 2-port valve, N.C. | G3/4, 1 | φ16 |

| VCH42 | 2-port valve, N.O | G3/4, 1 | φ17.5 |

| VCH410 | 3-port valve | G1/2 to 1 | φ18 |

| VCHC40 | Check valve | G3/4, 1 | φ16 |

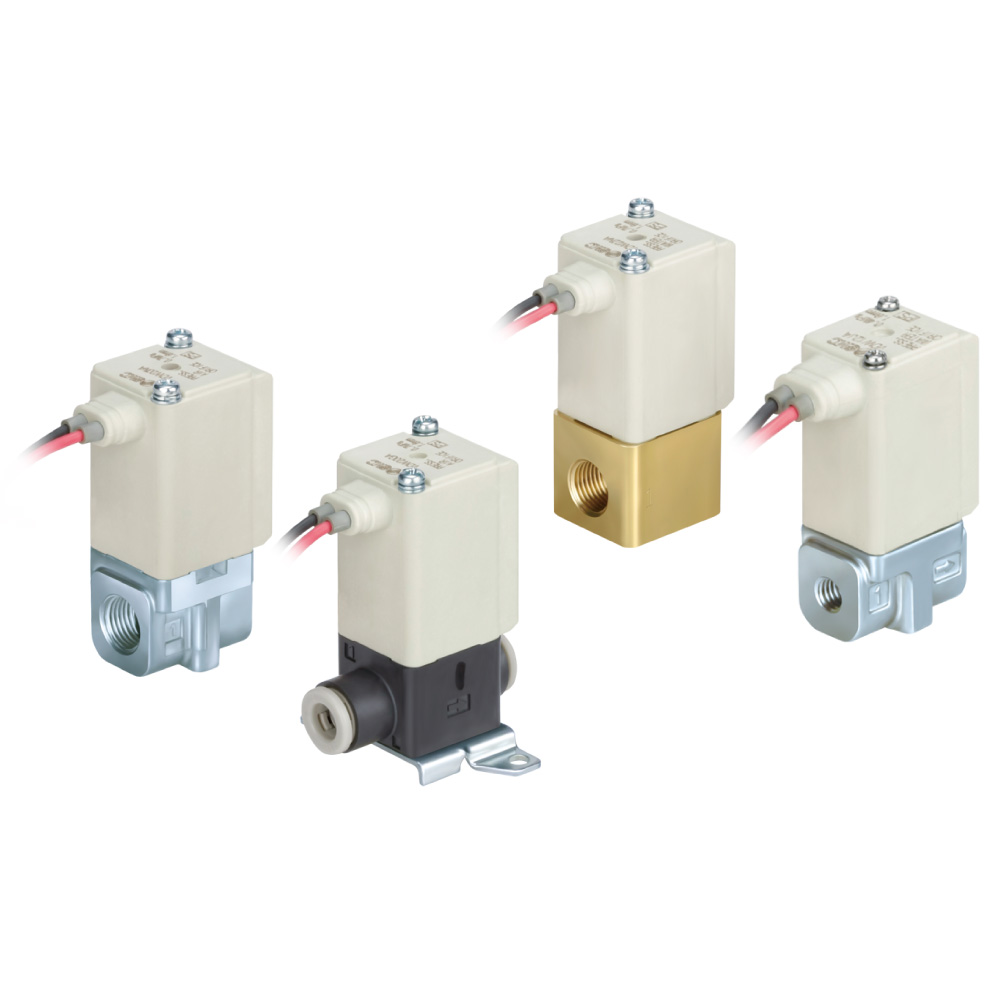

Compact Direct Operated 2 Port Solenoid Valve (2 Way Valve) VDW

Process Valves » Compact 2/3 Port Solenoid Valves/Air Operated ValvesEquipment for the Semiconductor Industries » Cooling Water Line

-

・For air, medium vacuum, water

・Body material: Aluminum, Resin (PPS), Brass, Stainless steel

・With One-touch fittings (resin body)

・IP65

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics Series Variations/Solenoid Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics Series Variations/Solenoid Valves List

Green Procurement (RoHS)

| Series | Valve type | Port size | Orifice diameter |

|---|---|---|---|

| VDW10/20 | N.C. | φ3.2, φ4, φ6, M5, 1/8 | φ1 to φ3.2 |

Direct Operated/Pilot Operated 2-Port Solenoid Valve JSX/JSX□

Process Valves » 2/3 Port Solenoid Valves/Air Operated ValvesEquipment for the Semiconductor Industries » Cooling Water Line

-

· Zero Differential Pressure Type Pilot Operated 2-Port Solenoid Valve

JSXZ Series has been added. New

· Improved environmental resistance due to the stainless steel coil cover

[IP67 enclosure/NEMA4X∗] ∗ IP65 for models with a DIN terminal

·Space saving

Compact: Valve volume reduced by 25%*, Lightweight: Weight reduced

by 30%*

* Compared with the existing model

·Energy saving

Coil force: 10% increase*, Power consumption: 14% reduction*

* Compared with the existing model

·360° lead wire insertion and removal is possible.

·Improved weather resistance in outdoor environments

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics

Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics

Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List

Green Procurement (RoHS)

| Series | Type | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|---|

| JSX | Direct operated | N.C/N.O. | 1/8, 1/4, 3/8 | 1.6 to 7.1 |

| JSX□□U | Direct operated high flow/ power saving type | N.C. | 1/8, 1/4, 3/8 | 2.4 to 7.1 |

| JSX□□V | Direct operated vacuum type | N.C. | 1/8, 1/4, 3/8 | 5.6 to 7.1 |

| JSX□□H | Direct operated high pressure type | N.C. | 1/4, 3/8 | 3.2 |

| JSX□□S | Direct operated steam type | N.C. | 1/4, 3/8 | 1.6,7.1 |

| JSXM | Direct operated modular mounting type | N.C. | 1/8,1/4,3/8,1/2 | 3.2,4 |

| JSXD | Pilot operated | N.C./N.O. | 1/4,3/8,1/2,3/4,1,1·1/4,1·1/2,2,32A,40A,50A | 10 to 50 |

| JSXP | Steam type | N.C. | 3/8,1/2,3/4,1,1·1/4,1·1/2,2,32A,40A,50A | 15 to 50 |

| JSXZ | Zero differential pressure type pilot operated | N.C. | 1/4,3/8,1/2,3/4,1 | 10 to 25 |