There were 1,109 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Vertical Suction Filter FHIA

Hydraulic Equipment » Hydraulic Equipment

-

・Vertical suction filters are designed for installation between the pump

and reservoir tank.

Their main function is to protect the pump.

・It is possible to detect clogging with the differential pressure indicator

and differential pressure indication switch (CB-□□H).

Safety Instructions Hydraulic Filters/Precautions Guide/INDEX Differential Pressure Indication Switch Green Procurement (RoHS)

| Series | Port size | Rated flow rate L/min | Operating pressure | Element μm (Nominal filtration) |

|---|---|---|---|---|

| FHIA | 1/2B to 4B | 30 to 1300 | Negative pressure | Micromesh : 74, 105, 149 |

Compact Hydraulic Cylinder CHQ/CHDQ

Hydraulic Equipment » Hydraulic Cylinders

-

・Lightweight, compact aluminum body

・It is possible to mount auto switches.

・Same longitudinal dimensions for cylinders with/without auto switches

・With auto switch (CHDQ series: CHDQ, CHDQW)

Safety Instructions Hydraulic Cylinders/Precautions Auto Switches/Precautions

Series Variations Technical Data Green Procurement (RoHS)

Series Variations Technical Data Green Procurement (RoHS)

| Series | Nominal pressure (MPa) | Body material | Action | Bore Size (mm) |

|---|---|---|---|---|

| CHQ | 3.5 | Aluminum | Double acting, Single rod | 20, 32, 40, 50 63, 80, 100 |

| CHQW | 3.5 | Aluminum | Double acting, Double rod | 20, 32, 40, 50 63, 80, 100 |

NAMUR Interface 3-Port Solenoid Valve VFN200N

Pneumatic Instrumentation Equipment » Solenoid Valves

-

・The interface surface is compliant with NAMUR Standards.

Can be directly installed on industrial valve actuators that comply with NAMUR

| Series | Flow rate characteristics 4/2→5/3(A/B→EA/EB) C | Flow rate characteristics 4/2→5/3(A/B→EA/EB) b | Flow rate characteristics 4/2→5/3(A/B→EA/EB) Cv | Power consumption (W) |

|---|---|---|---|---|

| VFN200N | 5.41 | 0.31 | 1.38 | 1.8 |

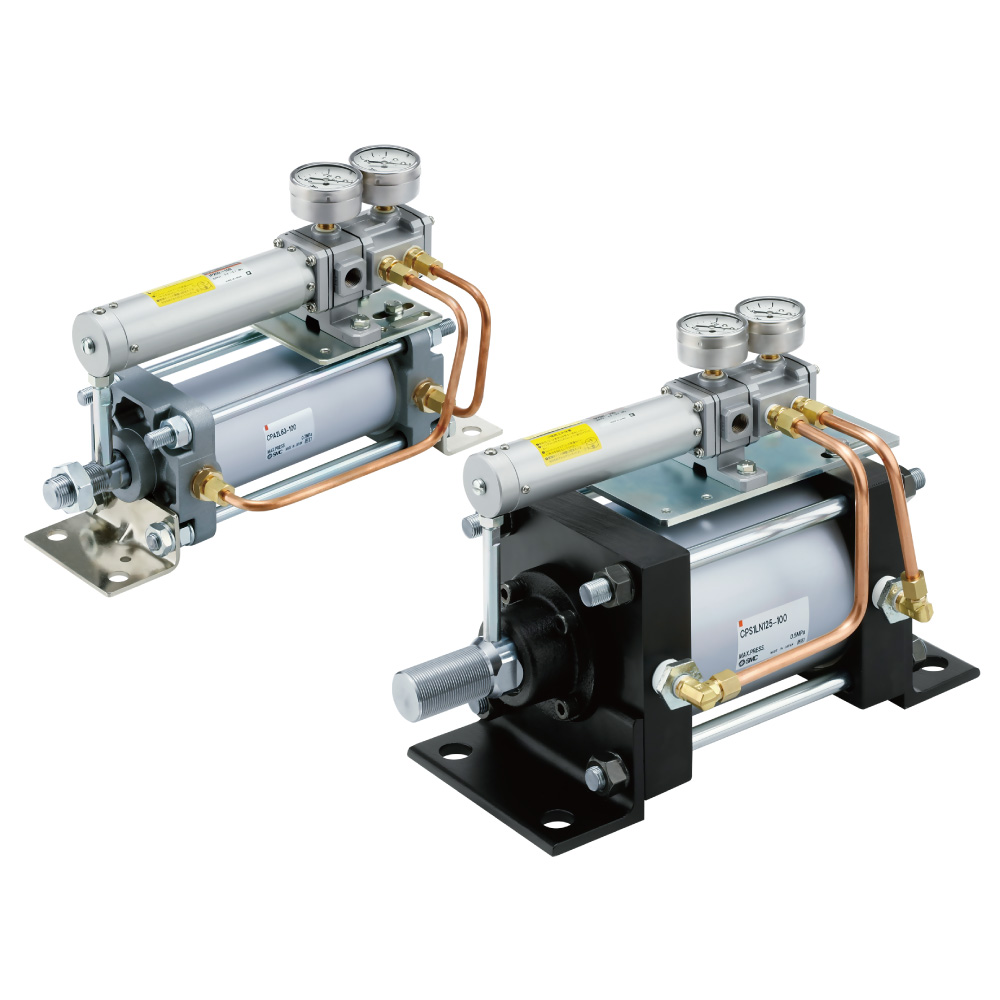

P Cylinder (Cylinder with Positioner) CPA2/CPS1

Pneumatic Instrumentation Equipment » Actuators

-

・Cylinder positioning in proportion to the input signal (air pressure) is possible.

・Correction operation function: Returns to the initial setting position even when the position deviates due to load variations

| Series | Bore size | Stroke (mm) | Air connection port | Supply pressure (MPa) | Input pressure (MPa) |

|---|---|---|---|---|---|

| CPA2 | φ50 to 100 | 25 to 300 | Rc1/4 female thread | 0.3 to 0.7 | 0.02 to 0.1 |

| CPS1 | φ125 to 300 | 30 to 300 | Rc1/4 female thread | 0.3 to 0.7 | 0.02 to 0.1 |

Industrial Filter/Vessel Series FGD

Industrial Filters/Sintered Metal Elements » Industrial Filters

-

・Ideal for low-flow filtration (Max. 60 L/min)

・It is possible to select the antistatic specification (FGDE, FGDF).

| Series | Port size | Max. operating pressure | Operating temperature (℃) |

|---|---|---|---|

| FGD | Rc3/8,1/2,3/4 | 0.7, 1 MPa | MAX. 80 |

Regulators for Ultra High Purity (UHP) AP/SL/AP/AZ

Process Gas Equipment AP Tech » Process Gas EquipmentEquipment for the Semiconductor Industries » N2 Gas/Air Supply Line

-

・For UHP gas delivery in semiconductor and other clean industries

・Body material: 316L SS secondary remelt or 316L SS

・Electropolished wetted parts

・External metal seal construction

Safety Instructions Process Gas Equipment/Common Precautions Series Variations Valve and Regulator Recommendations Technical Data/Glossary of Terms Green Procurement (RoHS)

| Series | Description | Type | Body material |

|---|---|---|---|

| AP | For Ultra High Purity | Single Stage Regulator | 316L SS secondary remelt |

| AP | For Ultra High Purity | Two Stage Regulator | 316L SS secondary remelt |

| AP | For Ultra High Purity | Pneumatic Actuation Pressure Regulator | 316L SS secondary remelt |

| SL | For Ultra High Purity | Single Stage Regulator | 316L SS secondary remelt |

| AZ | For Ultra High Purity | Single Stage Regulator | SUS316L |

| AZ | For Ultra High Purity | Pneumatic Actuation Pressure Regulator | SUS316L |

| AK | For General Applications | Single Stage Regulator | SUS316 |

| AK | For General Applications | Two Stage Regulator | SUS316 |

| AK | For General Applications | Pneumatic Actuation Pressure Regulator | SUS316 |

| BP | For Ultra High Purity | Back Pressure Regulator | SUS316 |

| BP | For General Applications· | Back Pressure Regulator | SUS316 |

Peltier-Type Thermo-con/Rack Mount Type

HECR

Temperature Control Equipment » Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)Equipment for the Semiconductor Industries (Temperature Adjustment Line) » Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

Temperature Adjustment Line » Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

-

・Good space utilization: Mountable in a 19-inch rack

Saves space by allowing multiple pieces of equipment to be mounted

together in a rack.

・Temperature stability: ±0.01℃ to 0.03℃

・Set temperature range: 10℃ to 60℃

・Cooling capacity: 200 W, 400 W, 510 W, 800 W, 1 kW, 1.2 kW

・Power consumption: 200 W, 300 W, 400 W

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method |

|---|---|---|---|---|

| HECR002-A | 10 to 60℃ | 200 W | ±0.01 to 0.03℃ | Peltier-type air-cooled |

| HECR004-A | 10 to 60℃ | 400 W | ±0.01 to 0.03℃ | Peltier-type air-cooled |

| HECR006-A | 10 to 60℃ | 510 W | ±0.01 to 0.03℃ | Peltier-type air-cooled |

| HECR006L-A | 10 to 60℃ | 510 W | ±0.01 to 0.03℃ | Peltier-type air-cooled |

| HECR008-A | 10 to 60℃ | 800 W | ±0.01 to 0.03℃ | Peltier-type air-cooled |

| HECR010-A | 10 to 60℃ | 1 kW | ±0.01 to 0.03℃ | Peltier-type air-cooled |

| HECR008-W | 10 to 60℃ | 800 W | ±0.01 to 0.03℃ | Peltier-type water-cooled |

| HECR012-W | 10 to 60℃ | 1.2 kW | ±0.01 to 0.03℃ | Peltier-type water-cooled |

EU F-Gas Regulation-compliant Refrigerated Thermo-chiller HRZ-F

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance/Type & Inverter Type

Equipment for the Semiconductor Industries (Temperature Adjustment Line) » Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance/Type & Inverter Type

Temperature Adjustment Line » Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance/Type & Inverter Type

-

・More effective energy-saving is achieved through use of a DC inverter compressor and an inverter pump.

・Energy saving

The inverter controls the number of motor rotations of the compressor and pump according to the load from the user’s application.

Power consumption: Max. 65% reduction

Facility water: Max. 67% reduction

・High performance

Temperature stability: ±0.1°C (When a load is stable)

Cooling time: Max. 46% reduction (SMC comparison)

・Refrigerant: R410A (HFC)/R448A (HFC/HFO)

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRZ-F | -20 to 40℃ 10 to 60℃ -20 to 90℃ | 2 kW, 4 kW, 8 kW, 10 kW | ±0.1℃ | Water-cooled refrigeration | Fluorinated fluids Ethylene glycol aqueous solution Tap water/Deionized water |

Thermo-chiller/Rack Mount Type HRR

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Rack Mount Type

Equipment for the Semiconductor Industries (Temperature Adjustment Line) » Thermo-Chillers (Circulating Fluid Temperature Controllers) Rack Mount Type

Temperature Adjustment Line » Thermo-Chillers (Circulating Fluid Temperature Controllers) Rack Mount Type

-

・Operable without the need to remove the unit from the rack

Front access: Simple to control, service, and maintain with all filters and drainage accessible via the front panel

・Space saving: Multiple chillers can be mounted to a 19-inch rack.

・Cooling capacity: 1.1/1.2/1.8/2.4/3.0/5.1 kW (60 Hz)

・Temperature stability: ±0.1℃

・Global power supply:

Single-phase 100 VAC (50/60 Hz)/115 VAC (60 Hz)

Single-phase 200 to 230 VAC (50/60 Hz)

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRR | 5 to 35℃ 15 to 35℃ | 1.1 kW 1.2 kW 1.8 kW 2.4 kW 3.0 kW 5.1 kW | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water Ethylene glycol aqueous solution (15%) |

Thermo-chiller/Dual Channel Thermo-chiller for Lasers HRL

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Dual Channel Thermo chiller for Lasers

-

・Temperatures for 2 fluid channel systems can be controlled individually

by one chiller.

・Space saving, Reduced wiring

Footprint: 22% reduction

One power supply system for 2 channels

・Energy saving

Power consumption reduced by 30%

・Touch panel

・Power supply:

3-phase 200 VAC (50 Hz)

3-phase 200 to 230 VAC (60 Hz)

3-phase 380 to 415 VAC (50/60 Hz)

3-phase 460 to 480 VAC (60 Hz)

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRL100 | CH1: 15 to 35℃ CH2: 10 to 40℃ | CH1:9 kw, CH2: 1.0 kW (Max. 5.0 kW) | CH1:±0.1, CH2:±0.5 | Air-cooled refrigeration, Water-cooled refrigeration | Tap water, Deionized water |

| HRL200 | CH1: 15 to 35℃ CH2: 10 to 40℃ | CH1:9 kw, CH2: 1.0 kW (Max. 5.0 kW) | CH1:±0.1, CH2:±0.5 | Air-cooled refrigeration, Water-cooled refrigeration | Tap water, Deionized water |

| HRL300 | CH1: 15 to 35℃ CH2: 10 to 40℃ | CH1:26 kw, CH2: 1.0 kW (Max. 5.0 kW) | CH1:±0.1, CH2:±0.5 | Air-cooled refrigeration | Tap water, Deionized water |

| HRL400 | CH1: 15 to 35℃ CH2: 10 to 40℃ | CH1:26 kw, CH2: 1.0 kW (Max. 5.0 kW) | CH1:±0.1, CH2:±0.5 | Air-cooled refrigeration | Tap water, Deionized water |