There were 361 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Vacuum Gripper System (Foam Type) ZGS

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: IO-Link Compatible ProductsGrippers for Collaborative Robots » Vacuum Grippers (Ejector Type)

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Gripper System (Foam Type)

IO-Link Devices » Vacuum Gripper System

-

・Foam size: 300 mm x 180 mm / 200 mm x 120 mm [New]

・Suitable for the palletizing and depalletizing of corrugated cardboard,

etc.

・Ejector unit

Combines all functions required for adsorption

(Ejector, Supply valve/Release valve, Silencer, Pressure switch)

・Can be used immediately by simply connecting 1 electrical cable and air

piping

・Compatible with the collaborative robots of 4 companies

UNIVERSAL ROBOTS, OMRON/TECHMAN ROBOT, FANUC,

YASKAWA Electric

・Lifting force

440 N (200 x 120) (At −63 kPa)

880 N (300 x 180) (At −63 kPa)

2144 N (400 x 240) (At −75 kPa)

・IO-Link compatible∗

∗ Only for sizes 300 x 180 and 200 x 120

▶IO-Link Devices

| Series | Cup form | Foam specifications Size | Theoretical lifting force [N] | Foam specifications Thickness |

|---|---|---|---|---|

| ZGS | Foam | 400 mm × 240 mm 300 mm × 180 mm 200 mm × 120 mm | 2144 [-75k Pa] 880 [-63 kPa] 440 [-63 kPa] | 20mm 30mm |

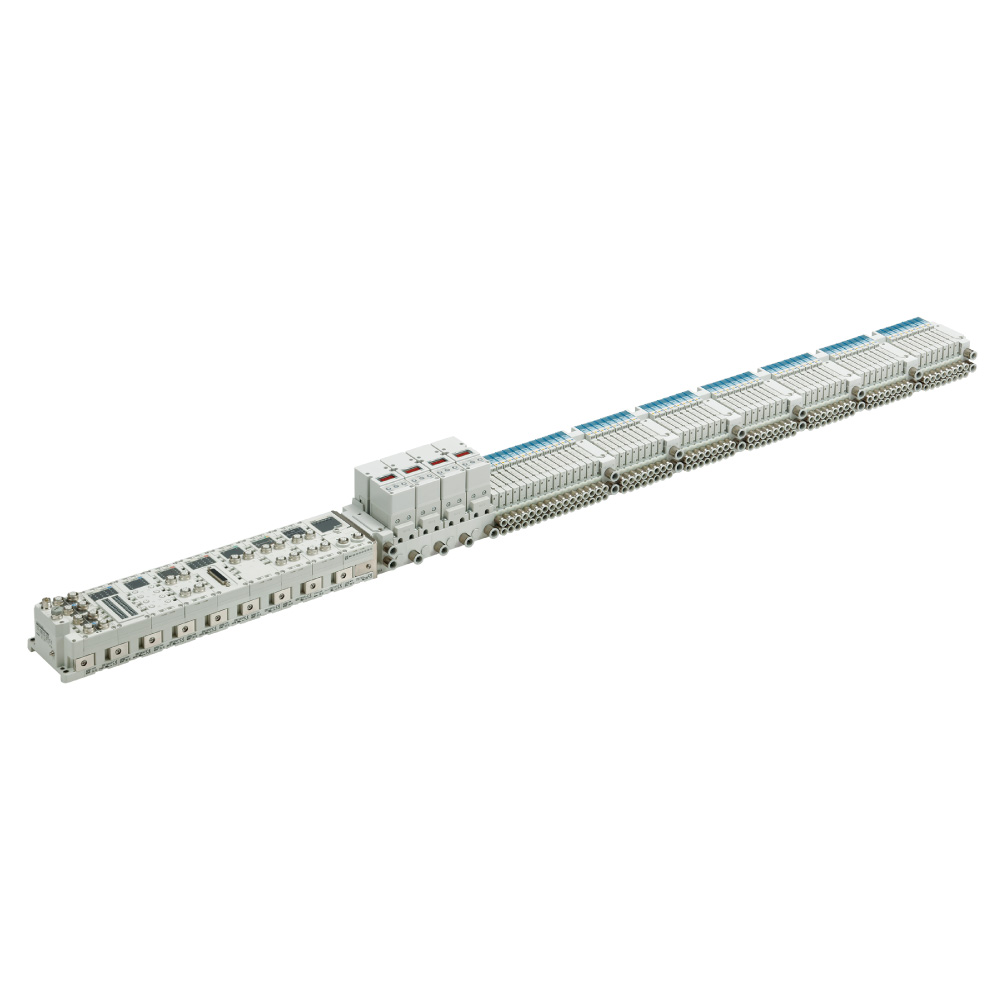

Electro-pneumatic Regulator Integrated Type 64-station Compatible Manifold Plug-in Compact 5-Port Solenoid Valve JSY3000-P

Directional Control Valves » Pilot Operated 4/5 Port Solenoid ValvesIndustrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: PROFINET Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherNet/IP Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherCAT Compatible Products

-

・Solenoid valves and electro-pneumatic regulators can be connected to

the same manifold.

Valve stations/Number of outputs: For 4 to 64 stations∗/128 points

∗ Stations are only available in multiples of 4.

Electro-pneumatic regulator stations: 1 to 4 stations

I/O unit stations: Max. 8 stations

・Equipment integration allows for the centralized management of control

and wiring as well as reduced wiring

Reduced wiring, Reduced number of SI units, Reduced wiring work,

Compact

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Enclosure | Communication protocol | Applicable devices |

|---|---|---|---|

| JSY3000-P | IP65 | PROFINET EtherNet/IP™ EtherCAT | SI unit: EX600 Valve: JSY3000 Electro-pneumatic regulator: ITV2340 |

Air Management System 25A-AMS20/30/40/60

Series Compatible with Secondary Batteries Series 25A- » Air Management System-

・Air consumption: Max. 62% reduction

Monitors the machine standby conditions (when production stops) and

automatically decreases the pressure.

Reduces unnecessary air consumption

・Compatible with OPC UA

Direct connection enables data communications.

・Compatible with wireless systems

Communication cables not required

High security thanks to unique encryption

Communication distance: Max. 100 m

・IO-Link compatible

| Series | Size | Port size | Flow capacity [L/min] | Communication protocol | Output data |

|---|---|---|---|---|---|

| Electro-Pneumatic Regulator Type

25A-AMS20A/30A/40A/60A | 20 30 40 60 | 1/8 1/4 3/8 1/2 3/4 1 | 5 to 500 10 to 1000 20 to 2000 40 to 4000 | PROFINET EtherNet/IP™ OPC UA EtherCAT | Instantaneous flow Accumulated flow Pressure Fluid temperature Various sensor information transmitted via IO-Link Diagnosis |

| Regulator Type

25A-AMS20B/30B/40B/60B | 20 30 40 60 | 1/8 1/4 3/8 1/2 3/4 1 | 5 to 500 10 to 1000 20 to 2000 40 to 4000 | PROFINET EtherNet/IP™ OPC UA EtherCAT | Instantaneous flow Accumulated flow Pressure Fluid temperature Various sensor information transmitted via IO-Link Diagnosis |

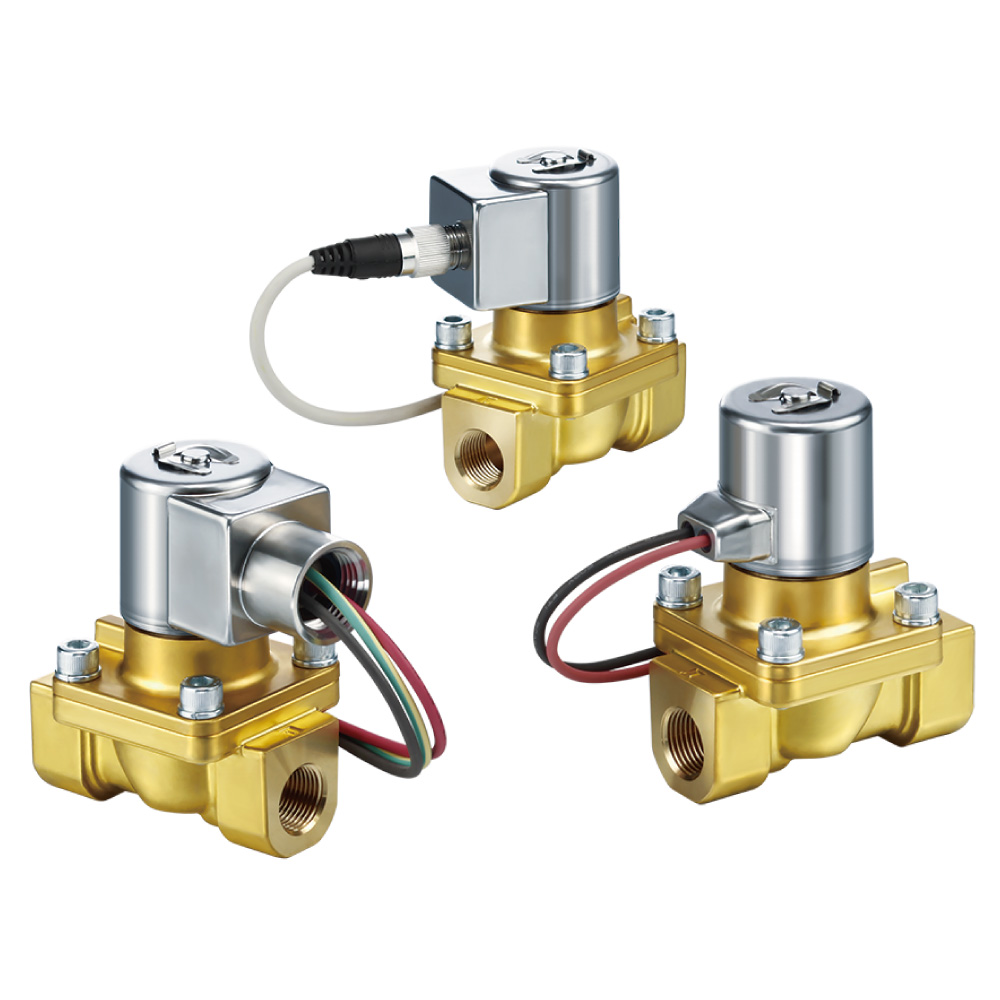

Pilot Operated 2-Port Solenoid Valve JSXH-X1

Process Valves » 2/3 Port Solenoid Valves/Air Operated Valves-

・Max. operating pressure differential: 4.0 MPa

Application examples: Blow molding, Laser processing machines,

Nitrogen filling unit

・Fluid: Compressed air, Nitrogen, Argon, Oxygen∗

∗ When using oxygen, please refer to "Fluid Supply."

・Improved environmental resistance

Dustproof/waterproof IP67 structure (IP65 for the DIN terminal)

With a stainless steel coil cover

・Low particle generation

・Oil-free

・Easy maintenance

The coil can be replaced by simply removing the clip.

・Power saving (Power consumption: 6 W)

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions Model Selection/Flow Rate Characteristics Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List Green Procurement (RoHS)

| Series | Type | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|---|

| JSXH-X1 | Pilot operated | N.C. | 3/8,1/2 | 16 |

Compact Cylinder / High Power Type CQE

Air Cylinders » Compact Air Cylinders-

・Theoretical output: Max. 1.5 times

・This is done even with the same external dimensions of the CQ2 series.

・The theoretical output of the next larger bore sized cylinder is made

possible with the polygonal piston shape.

・Contributes to a lower pressure air line, Supply pressure decreased by

0.17 MPa

The same theoretical output is available even when the supply pressure

to the cylinder is decreased.

Safety Instructions Actuators/Precautions Auto Switches/Precautions

Model Selection/Technical Data Green Procurement (RoHS)

Model Selection/Technical Data Green Procurement (RoHS)

| Type | Series | Action | Bore size [mm] |

|---|---|---|---|

| High power type | CQE | Double acting, Single rod | 20,25,32,40 |

Longer Life Cylinder C85/C75-XB24

Air Cylinders » ISO Cylinders: ISO Standards (6432)-

・New technology offers at least 4 times better durability.

・The maintenance intervals will be extended.

・Employs the same specification and dimensions as the existing models,

C85 ISO Cylinder series and C75 Air Cylinder series.

Safety Instructions Actuators/Precautions Auto Switches/Precautions Model Selection/Technical Data Green Procurement (RoHS)

| Type | Series | Action | Bore size (mm) |

|---|---|---|---|

| Longer life | C85-XB24 | Double acting Single rod | 8,10,12,16,20,25 |

| Longer life | C75-XB24 | Double acting Single rod | 32,40 |

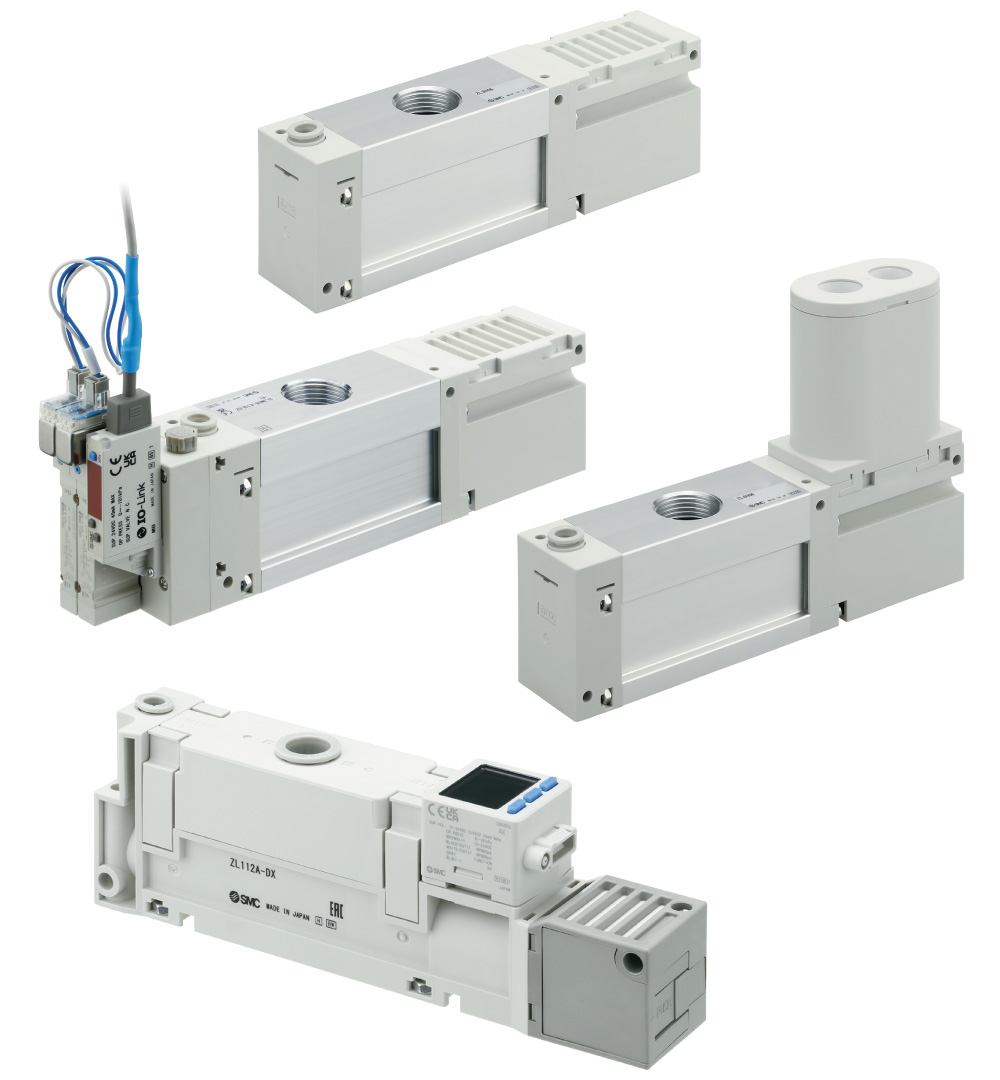

Multistage Ejector ZL1/ZL3/ZL6

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems-

・An IO-Link compatible vacuum pressure switch has been added. (ZL3,

ZL6) New

Allows for ejector control with a single communication line

Reading of the device information and parameter batch settings are

possible.

・Max. suction flow rate: 3 types available: 100, 300, and 600 L/min (ANR)

・Air consumption: 91% reduction (ZL3, ZL6)

Reduced by the pressure switch for vacuum with energy saving function

and efficient ejectors

・Weight: Max. 60% reduction [ZL112 (Existing model): 450 g → ZL1: 180 g]

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|

| ZL1 | 1.2 | 100 | 57 |

| ZL3M | 1.9 | 300※1 | 150 |

| ZL3H | 1.5 | 300※1 | 135 |

| ZL6M | 1.9×2 | 600※1 | 300 |

| ZL6H | 1.5×2 | 600※1 | 270 |

Electric Vacuum Gripper for Collaborative Robots ZXPE5

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Gripper for Collaborative RobotsElectric Actuators/Cylinders » Grippers for Collaborative Robots

Grippers for Collaborative Robots » Electric Vacuum Grippers (Built-in Vacuum Pump Type)

-

・A vacuum gripper that doesn't require an air source

・Operation possible by simply connecting an electrical wire connector

Can be used without an air source due to the built-in vacuum pump

・Unitization of the peripheral devices required for adsorption

The vacuum pump, atmospheric release valve, pressure monitor,

and cups have been integrated.

・Current consumption: Max. 64% reduction

Energy-saving operation possible via automatic/manual modes

・Lightweight: 556 g

・A wide variety of cup variations are available to support a wide range of

workpiece shapes.

・Standards: Conforming to ISO9409-1-50-4-M6

∗1 These are the values under SMC measurement conditions when the gripper is in continuous mode (the vacuum pump working continuously) and may vary depending on the

atmospheric pressure (weather, altitude, etc.) and the measurement method.

∗2 May be restricted depending on the cup diameter, mounting orientation, or workpiece. Please use within the max. work load. Suction and transfer exceeding the max. work load may result in product failure and the dropping of workpieces.

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Cup form | Cup diameter | Max. suction flow rate*1 [L/min(ANR)] | Max. work load*2

[Kg] |

|---|---|---|---|---|

| ZXPE5 | Flat Flat with rib Bellows Thin flat Multistage bellows 2.5-stage bellows 5.5-stage bellows Flat type for film packaging workpieces | φ8 to φ32 | 4.5 | 5 |

Non F-Gas Uses (CO2 Refrigerant) Thermo-chillers for the Semiconductor Industry INR-495-042/INR-495-043

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: DeviceNet Compatible Products

Temperature Control Equipment » Chiller Compliant Regulations

-

・Non F-Gas (CO2 refrigerant R744)

・GWP: 1 (Natural refrigerant)

・EU refrigerant regulations: GWP150 or less∗

・US refrigerant regulations: GWP700 or less∗

・California, US refrigerant regulations: GWP750 or less

∗As of December 2023

・Air transport possible

No air transport restrictions for non-toxic and non-flammable∗

refrigerants

∗A1 (ASHRAE34 standard)

・No F-Gas management required

Eliminates the need for periodic inspections based on the Fluorocarbon

Emissions Control Act (Japan)

・No F-Gas recovery & disposal costs

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| INR-495-042 INR-495-043 | -20 to 70 | 8.5 kW | ±1.0℃ | Water-cooled refrigeration | Fluorinated fluid |

3-Screen Display Condensation Checker (Digital Temperature & Humidity Switch) PSH

Switches/Sensors/Controller » Electronic Temperature & Humidity Switches-

・A relative humidity under pressure (inside piping) display function has

been added. New

・A condensation checker can prevent such problems!

Allows for the visualization of humidity inside piping

Detects abnormalities prior to condensation generation

・Can be easily connected to any pipe you want to monitor

Compact size allows for easy installation

・Visualization of relative humidity

Real-time monitoring

・Remote/Condition monitoring

Remote confirmation via switch output preventing condensation

problems!

Safety Instructions Pressure Switches/Flow Switches/Precautions Pressure Switch Series Variations/Application Example Glossary of Terms/Technical Information Green Procurement (RoHS) Proposal for Condensation Checker Installation

| Series | Set temperature range | Set relative humidity range | Display accuracy |

|---|---|---|---|

| PSH | -5 to 55°C | 0 to 100% R.H. (No condensation) | Temperature: ±3°C ±1 digit Humidity: ±5% R.H. ±1 digit |