There were 10 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Mechanical Valves HF1-/HF1A (Compatible) /HF1B (Compatible)

Equipment for the Food Manufacturing Industry » Directional Control Valves| Series | Model | Specification |

|---|---|---|

| Mechanical Valve | HF1B-VM1000/VM100/VM200/VM400 | HF1B |

Blow Gun VMG

Directional Control Valves » Blow GunsAir Blowing Equipment » Air Blowing Equipment

-

・A 20% reduction in power consumption can be achieved with the SMC “Blow gun” + “S coupler” + “Coil tube.”

・Pressure loss: 1% or less (Nozzle size: ø2.5)

・Available nozzles:

Male thread nozzle, High efficiency nozzle with male thread,

Low noise nozzle with male thread, Copper extension nozzle

・With flow rate adjustment function (-X54)

| Series | Port size | Operating pressure range (MPa) | Effective area (mm2) | Nozzle port size |

|---|---|---|---|---|

| VMG | Rc,NPT,G 1/4,3/8 | 0 to 1.0 | 30 | Rc1/4 |

2/3-Port Mechanical Valve with One-touch Fitting VM100F

Directional Control Valves » Mechanical Valves/Transmitters-

・Built-in One-touch fitting reduced installation space and less piping work

・Space saving

Approx. 35% reduction (25.8 mm shorter) due to the built-in One-touch fitting

・Lightweight

80% reduction (48 g lighter) due to the resin body material

・Less man-hours replacing the actuator

Mounting using a clip makes replacement easier.

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions

Series Variation Selection/Technical Data Green Procurement (RoHS)

Series Variation Selection/Technical Data Green Procurement (RoHS)

| Description | Series | Number of ports |

|---|---|---|

| Mechanical valve | VM100F | 2/3-ports |

Nozzles for Blowing KN

Air Blowing Equipment » Air Blowing Equipment

-

*Refer to the Operation Manual (VMG) for details on how to mount the copper extension nozzle set.

Click here for details on Operation Manual (VMG).

| Series | Type | Nozzle size |

|---|---|---|

| KN | Nozzle with self-align fitting | ø1 to ø6 |

| KN | Nozzle with male thread | ø1 to ø8 |

| KNC | Nozzle with flow rate adjustment function | ø2.6 |

| KNL | Copper extension nozzle | ø1.5 to ø3 |

| VMG | Copper extension nozzle set | ø1.5 to ø3.5 |

| KN-Q□A | Nozzle for One-touch fitting (Resin type) | ø1 to ø3 |

| KN-Q□ | Nozzle for One-touch fitting (Metal type) | ø1 to ø3 |

| KNK | Pivoting nozzle with self-align fitting | ø4, ø6 |

| KNK | Pivoting nozzle with male thread | ø4, ø6 |

| KNH | High efficiency nozzle | ø1 to ø2 |

| KNS | Low noise nozzle with self-align fitting | ø0.75 x 4 to ø1 x 4 |

| KNS | Low noise nozzle with male thread | ø0.75 x 4 to ø1.1 x 8 |

| KNP | Standard sensing head | ø2.5 |

| KNP | Needle sensing head | ø0.7 |

| P5670129-□ | Nozzle cover | Refer to the catalog. |

| KN-R03-400-X1484 | Blower nozzle (Made to order) | 4 x 11 (Nozzle port size) |

| KN-06-150-X1567 | Bender tube (Made to order) | ø1.5 |

| KN | Stainless steel nozzle (Made to order) | Refer to the catalog. |

| ZH-X226 ZH-X338 ZH-X249 | Vacuum flow | Refer to the catalog. |

Mechanical Valve VM/VZM/VFM

Directional Control Valves » Mechanical Valves/Transmitters-

・A wide variety of valves are available for all types of air systems.

・Small mounting space with a compact body

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Series Variation Selection/Technical Data Green Procurement (RoHS)

| Description | Series | Number of ports |

|---|---|---|

| Mechanical valve | VM1000 | 2/3 ports |

| Mechanical valve | VM100,VM200 | 2/3 ports |

| Mechanical valve | VM400 | 3 ports |

| Mechanical valve | VZM500,VZM400 | 5 ports |

| Mechanical valve | VFM300,VFM200 | 5 ports |

| Mechanical valve | VM800 | 3 ports |

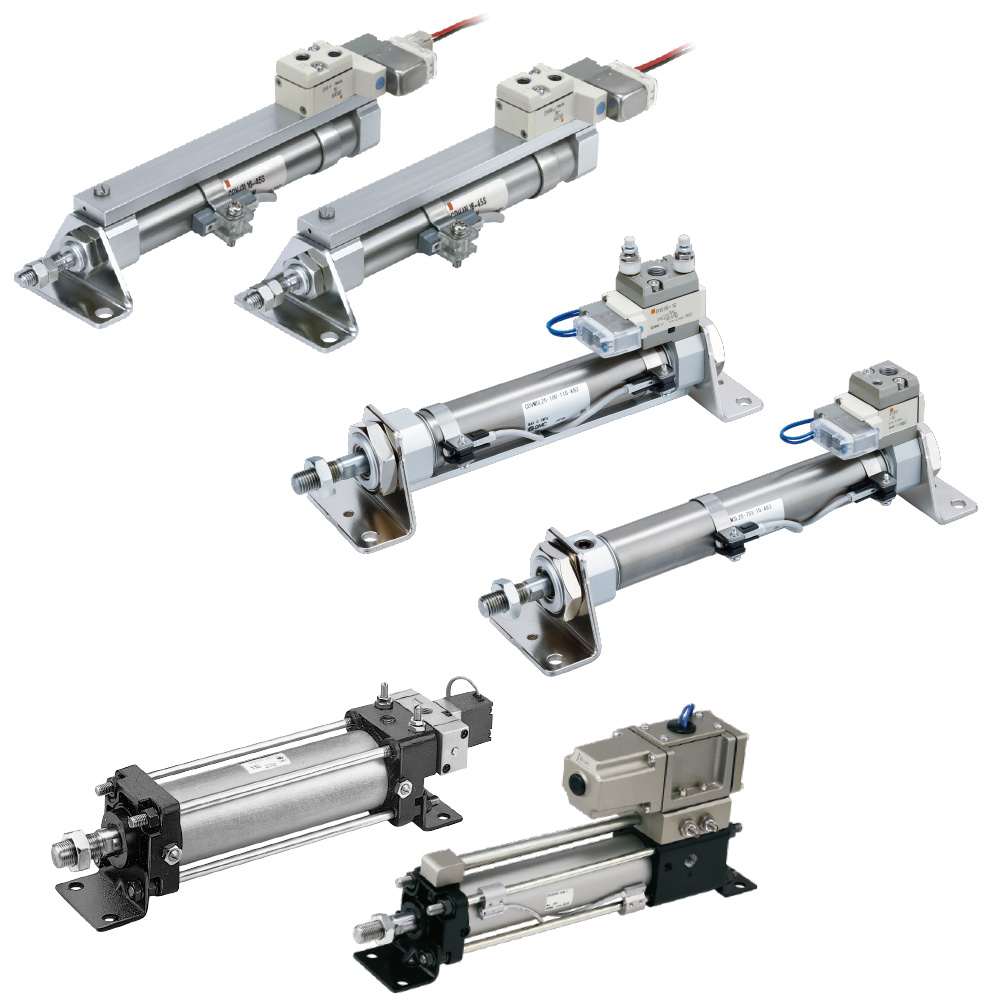

Valve Mounted Air Cylinder CV□/CDV□

Air Cylinders » Valve Mounted Air Cylinders

-

・Valve is mounted on a round cylinder.

・Built-in speed controller for some models

・A cylinder with a valve makes it easy to adjust the speed.

・With auto switch (CDVJ series: CDVJ5, CDVJ3,

CDVM series: CDVM5, CDVM5K, CDVM3, CDVM3K,

CDV3 series: CDV3, CDV3K,

CDVS1 series: CDVS1)

Safety Instructions Actuators/Precautions Auto Switches/Precautions

Model Selection/Technical Data Simple Specials

CV Series/Precautions Made to Order Common Specifications

Green Procurement (RoHS)

Model Selection/Technical Data Simple Specials

CV Series/Precautions Made to Order Common Specifications

Green Procurement (RoHS)

| Type | Series | Action | Bore size (mm) | Component Cylinder | Component Valve |

|---|---|---|---|---|---|

| Standard | CVJ5 | Double acting, Single rod | 10,16 | CJ2 | SYJ3190 |

| Standard | CVJ3 | Single acting (Spring return/Extend) | 10,16 | CJ2 | SYJ319 |

| Standard | CVM5 | Double acting, Single rod | 20,25 32,40 | CM2 | VZ3□90 |

| Standard | CVM3 | Single acting (Spring return/Extend) | 20,25 32,40 | CM2 | VZ319 |

| Standard | CV3 | Double acting, Single rod | 40,50,63 80,100 | CA2-Z | V3□08 |

| Standard | CVS1 | Double acting, Single rod | 40,50,63 80,100 | CA2-Z | VS4□24 |

| Non-rotating rod | CVM5K | Double acting, Single rod | 20,25 32,40 | CM2K | VZ3□90 |

| Non-rotating rod | CVM3K | Single acting (Spring return/Extend) | 20,25 32,40 | CM2K | VZ319 |

| Non-rotating rod | CV3K | Double acting, Single rod | 40,50,63 | CA1K | V3□08 |

Air Saving Impact Blow Gun IBG

Directional Control Valves » Blow GunsAir Blowing Equipment » Air Blowing Equipment

-

・Various functions

Pulse function [New]

Adjuster function with indicator

・Increased impact force due to higher peak pressure

Drastic reduction in air consumption and labor time

・Application: It is capable of eliminating, in a short period of time,

the dust, etc., that is difficult to remove with the existing blow gun.

| Series | Peak pressure∗1 | Size (Height x Depth x Width) [mm] | Weight [g] | Tank capacity [cc] | Air consumption∗2 [cc] | Supply port |

|---|---|---|---|---|---|---|

| IBG1 High Peak Pressure Type | 3 times or more | 183.8 × 83 × 41 | 380 | 100 | 600 | Screw-in type (Rc, NPT, G) 3/8 One-touch fittings ø6 to ø10 ø1/4" to ø3/8" S coupler R3/8 |

| IBG2 Compact Type | 2.5 times or more | 174.5 × 76 × 41 | 300 | 70 | 420 | Screw-in type (Rc, NPT, G) 1/4 One-touch fittings ø6 to ø10 ø1/4" to ø3/8" S coupler R1/4 |

| ∗1 Compared with the existing VMG series model | ∗2 The amount of air filled in the tank at 0.5 MPa operating pressure |

Compact Direct Operated 2/3-Port Solenoid Valve for Chemical Liquids LVM

Process Valves » Compact 2/3 Port Solenoid Valves/Air Operated ValvesChemical Liquid Valves/Fittings & Needle Valves/Tubing » Chemical Liquid Valves

-

・Low particle generation, Oil-free, Metal-free * Fluid contact parts

・Isolated structure

The solenoid drive body is separated from the fluid area by a diaphragm.

・Power consumption: 1.0 W or less (With power saving circuit)

・Change in volume (Pumping volume): 0.01 µL or less

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions Model Selection/Flow Rate Characteristics Series Variations Green Procurement (RoHS)

| Series | Valve construction | Valve type | Operating pressure range | Orifice diameter (mmø) |

|---|---|---|---|---|

| LVM07 Base mounted | Direct operated rocker type | N.C. | -75 kPa to 0.1 MPa | 0.8 |

| LVM09 Body ported Base mounted | Direct operated rocker type | N.C. N.O. Universal | -75 kPa to 0.2 MPa | 1 (Body ported) 1.1 (Base mounted) |

| LVM10 Body ported Base mounted | Direct operated rocker type | N.C. N.O. Universal | -75 kPa to 0.25 MPa | 1.4 |

| LVM15 Body ported Base mounted | Direct operated rocker type | N.C. N.O. Universal | -75 kPa to 0.25 MPa (Max. 0.6 MPa) | 1.6 1 (High-pressure type) |

| LVM20 Body ported Base mounted | Direct operated rocker type | N.C. N.O. Universal | -75 kPa to 0.3 MPa (Body ported: 0.25 MPa) | 2 |

| LVM1□ Body ported Base mounted | Direct operated poppet type | N.C. | 0 to 0.25 MPa | 1.5 |

| LVM3□ Body ported Base mounted | Direct operated poppet type | N.C. | -90 kPa to 0.2 MPa | 5 |

Direct Operated 2/3 Port Isolated Valve LVMK20/200

Process Valves » Compact 2/3 Port Solenoid Valves-

・Low particle generation, Oil-free, Metal-free

・Fluids: Air, Water, Deionized water, Diluent, Cleaning fluid

・Isolated structure: The solenoid drive body is separated from the fluid area by a block seal.

・Easy piping

・Minimal dead space

・Flow adjustment is not required.

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions Series Variations Green Procurement (RoHS)

| Series | Valve type | Piping direction | Fluid contact material |

|---|---|---|---|

| LVMK | N.C. Universal | Bottom ported Side ported | Body: PPS Seal: EPDM, FKM |

Pinch Valve LPV

Process Valves » Compact 2/3 Port Solenoid Valves-

・A 3-port type has been added. [New]

Valve type

N.C. on one side (Normally in clamping position)

N.O. on one side (Normally in unclamping position)

・Highly resistant to contamination and reduces valve failures

・Applicable tubing:

Silicone, PharMed®BPT, Tygon®

・Power consumption: 2.0 W

・Compact: Valve width 20 mm

・Easy tubing replacement

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions Series Variations Green Procurement (RoHS)

| Series | Type of actuation | Valve type | Applicable tubing |

|---|---|---|---|

| LPV | Direct operated solenoid | N.C. N.O. | Silicone, PharMed®BPT“Hardness of 64 (shore A) or lower (reference)” |