There were 1,029 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

JIS Standard Compact Hydraulic Cylinder CHK□/CHDK□

Hydraulic Equipment » Hydraulic Cylinders

-

・Lightweight, compact aluminum body

・It is possible to mount auto switches.

・Same longitudinal dimensions for cylinders with/without auto switches

・Compliant with JIS Standards (CHKD series)

・With auto switch (CHDK□ series: CHDKD, CHDKG)

Safety Instructions Hydraulic Cylinders/Precautions Auto Switches/Precautions

Series Variations Technical Data Green Procurement (RoHS)

Series Variations Technical Data Green Procurement (RoHS)

| Series | Nominal pressure (MPa) | Body material | Action | Bore Size (mm) |

|---|---|---|---|---|

| CHKD | 10 | Aluminum | Double acting, Single rod | 20, 25, 32, 40, 50 63, 80, 100 |

| CHKG | 16 | Aluminum | Double acting, Single rod | 20, 25, 32, 40, 50 63, 80, 100 |

Reinforced Corrugated Cardboard Specification/Longer Length Reel: Nylon Tubing T0604-X64

Pneumatic Instrumentation Equipment » Piping Materials

-

・Length per roll: 500/250 m

・For general pneumatic tubing

・Nylon tubing

| Series | Tube size Tubing O.D. ×Tubing I.D. | Fluid |

|---|---|---|

| T0604-X64 | φ6×φ4 | Air/Oil, Water |

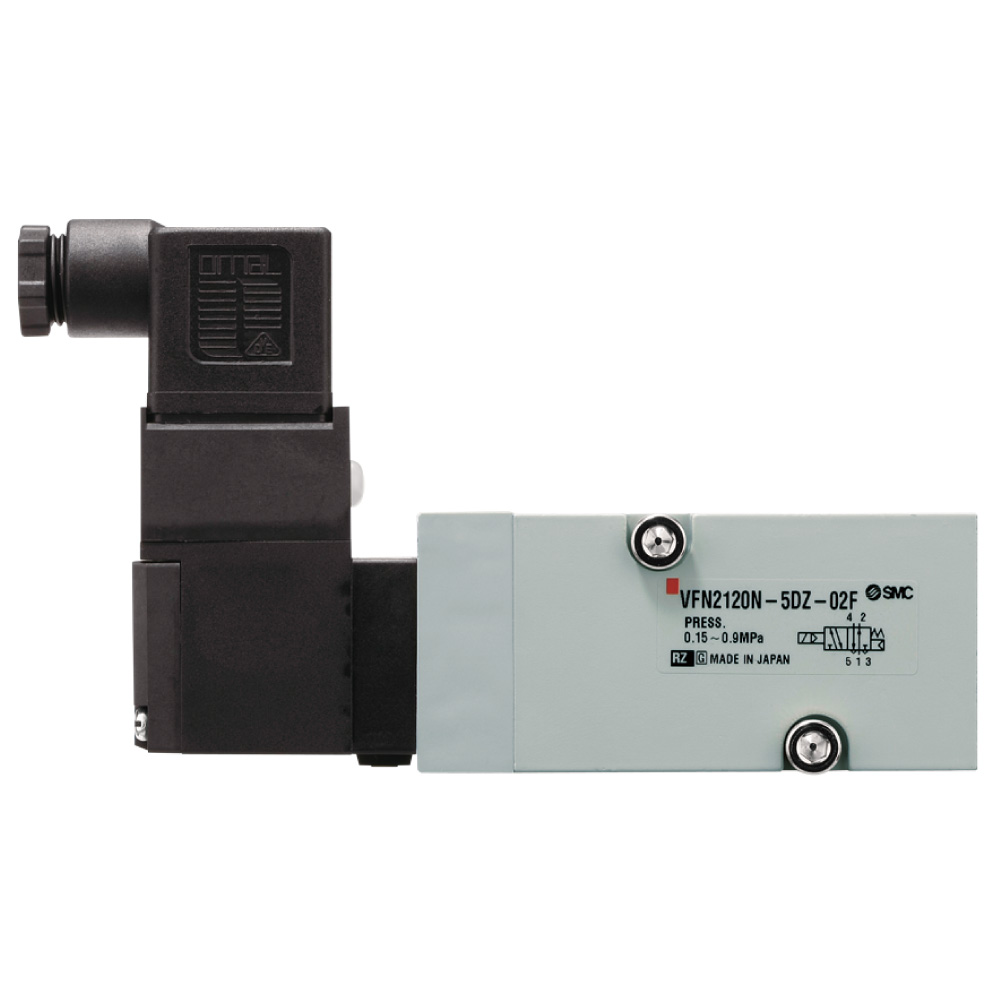

NAMUR Interface 5-Port Solenoid Valve VFN2000N

Pneumatic Instrumentation Equipment » Solenoid Valves

-

・The interface surface is compliant with NAMUR Standards.

Can be directly installed on industrial valve actuators that comply with NAMUR

| Series | Flow rate characteristics 4/2→5/3(A/B→EA/EB) C | Flow rate characteristics 4/2→5/3(A/B→EA/EB) b | Flow rate characteristics 4/2→5/3(A/B→EA/EB) Cv | Power consumption (W) |

|---|---|---|---|---|

| VFN2000N | 4.57 | 0.17 | 1.06 | 1.8 |

Industrial Filter/Vessel Series FGE

Industrial Filters/Sintered Metal Elements » Industrial Filters

-

・Ideal for medium flow rate filtration (Max. 230 L/min)

・Easy element replacement for the V-band type

(With cover anti-scattering mechanism)

| Series | Port size | Max. operating pressure | Operating temperature (℃) |

|---|---|---|---|

| FGE | R1, 2 | 0.7 MPa | MAX. 80 |

Slit Valve XGT

High Vacuum Equipment » Slit ValvesEquipment for the Semiconductor Industries » Slit Valve/Transfer

-

・This product is suitable to act as the partition valve between the load lock chamber and the transfer chamber or between the transfer chamber and the process chamber in semiconductor equipment or other equipment.

Safety Instructions System Configuration/Role of Each Line and Component Series Variations Glossary Green Procurement (RoHS)

| Series | Operating environmental pressure (Pa)(abs) | Fluid | Opening window size (Height x Width) (mm) | Operating pressure (MPa)(G) |

|---|---|---|---|---|

| XGT | Atmospheric pressure to 10-6 | Inert gas type vacuum | 32 x 222 46 x 236 50 x 336 | 0.45 to 0.6 |

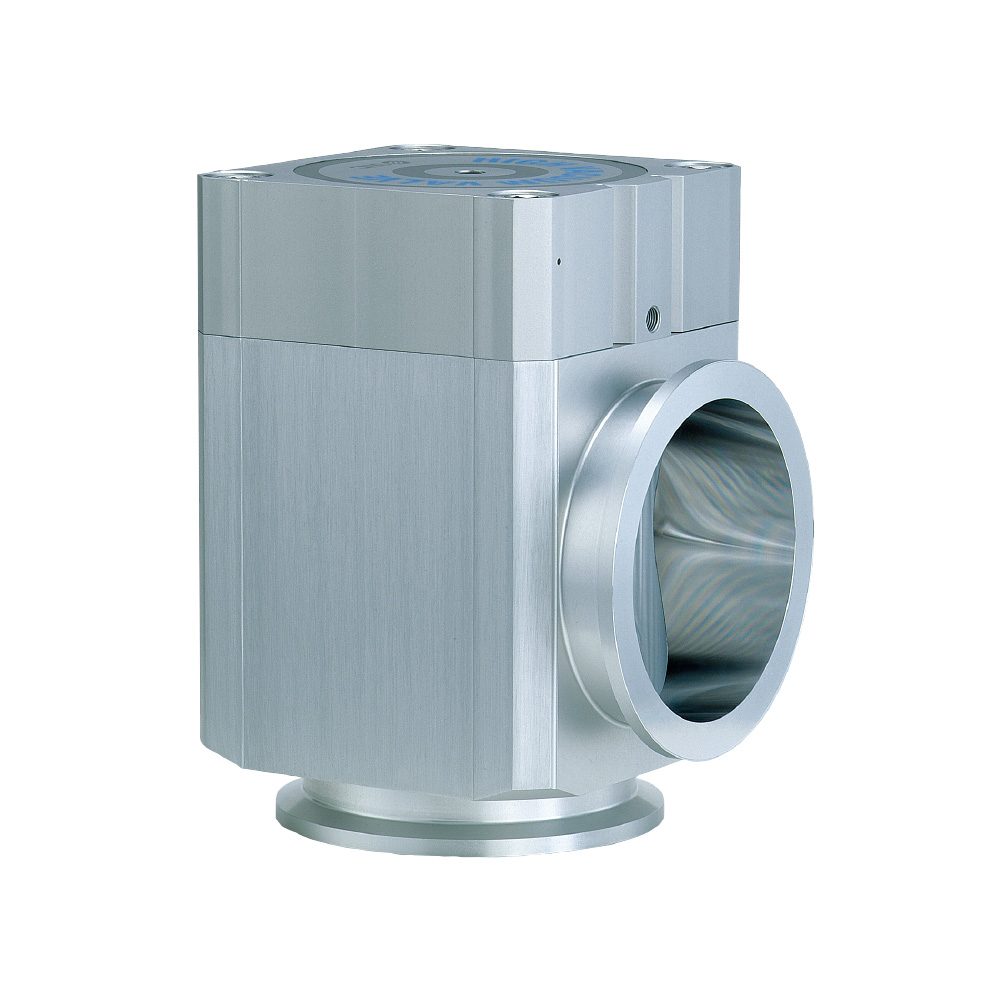

Aluminum High Vacuum Angle Valve XLA/C-100/160(-1)-X152

High Vacuum Equipment » High Vacuum ValvesEquipment for the Semiconductor Industries » Exhaust Line

-

・Improved durability of bellows (Flange sizes 100 and 160)

・Service life of two million cycles

・Space required for equipment can be reduced

Without restriction on exhaust direction (two ways: from valve element side to bellows side and vice versa)

Increased flexibility of mounting orientation

・Lightweight, Compact

Safety Instructions System Configuration/Role of Each Line and Component Series Variations Glossary Auto Switches Common Specifications Green Procurement (RoHS)

| Series | Actuation | Valve type | Shaft seal type | Application | Flange size |

|---|---|---|---|---|---|

| XLA-100/160-X152 | Air operated | Single acting (N.C.) | Bellows seal | Dust free, Cleaned | 100,160 |

| XLC-100/160-1-X152 | Air operated | Double acting | Bellows seal | Dust free, Cleaned | 100,160 |

Peltier-Type Thermo-con HEC

Temperature Control Equipment » Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)Equipment for the Semiconductor Industries (Temperature Adjustment Line) » Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

Temperature Adjustment Line » Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

-

・For applications requiring high-precision temperature control

・High-precision, refrigerant-free temperature control equipment that uses a Peltier

device

・Simple structure and high reliability

・Can easily be built into equipment due to its compact and low-vibration design

・Compatible with a wide range of power supply voltages

・Compliant with UL Standards, CE-marking

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HEC | 10 to 60℃ | 230 W, 600 W | ±0.01 to 0.03℃ | Peltier-type air-cooled | Tap water |

| HEC | 10 to 60℃ | 140 W, 320 W | ±0.01 to 0.03℃ | Peltier-type water-cooled | Tap water, Ethylene glycol aqueous solution (20%) |

| HEC | 10 to 60℃ | 600 W, 1200 W | ±0.01 to 0.03℃ | Peltier-type water-cooled | Tap water, Fluorinated fluid |

Water-cooled Thermo-chiller/High-performance Type HRW

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: DeviceNet Compatible ProductsTemperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance/Type & Inverter Type

Equipment for the Semiconductor Industries (Temperature Adjustment Line) » Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance/Type & Inverter Type

Temperature Adjustment Line » Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance/Type & Inverter Type

-

・Direct heat exchanger for in-plant circulating fluid

・Can control the temperature over a wide range since a compressor is not required.

・Suitable for semiconductor processing equipment with a wide variety of features, such as high-temperature stability, a wide temperature range, failure diagnosis, external communication, etc.

・Compliant with UL Standards, SEMI Standards, CE-marking

・It is possible to select the inverter type.

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRW | 20 to 90℃ | 2 kW, 8 kW, 15 kW, 30 kW | ±0.3℃ | Water-cooled type (Without compressor) | Fluorinated, Tap water, Deionized water, Ethylene glycol aqueous solution (60%) |

Thermo-chiller Compact Dual/Basic Type for Lasers HRLE

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Dual Channel Thermo chiller for Lasers-

・The temperatures of 2 fluid channel systems can be controlled individually by 1 chiller.

・Space saving, Reduced wiring

Footprint reduced by 21%

One power supply system for 2 channels

・Energy saving

Power consumption reduced by 17%

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity (CH1, 2 total) | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRLE050-A | CH1:15 to 25℃ CH2:CH1 temperature + 0 to 15℃ | 4.8kW/5.8k (50Hz/60Hz) | CH1:±0.1 CH2:±0.5 | Air-cooled refrigeration | Tap water, Deionized (pure) water |

| HRLE050-W | CH1:15 to 25℃ CH2:CH1 temperature + 0 to 15℃ | 4.8kW/5.8k (50Hz/60Hz) | CH1:±0.1 CH2:±0.5 | Water-cooled refrigeration | Tap water, Deionized (pure) water |

| HRLE090-A | CH1:15 to 25℃ CH2:CH1 temperature + 0 to 15℃ | 8.0 kW/9.5 kW (50 Hz/60 Hz) | CH1: ±0.1 CH2: ±0.5 | Air-cooled refrigeration | Tap water, Deionized (pure) water |

| HRLE090-W | CH1: 9 kw,19 kW, 26 kW CH2: 1.0 kW (Max. 1.5 kW) | 9.5 kW/11.0 kW (50 Hz/60 Hz) | CH1: ±0.1 CH2: ±0.5 | Water-cooled refrigeration | Tap water, Deionized (pure) water |

Thermo-chiller/Inverter Type HRSH

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

Equipment for the Semiconductor Industries (Temperature Adjustment Line) » Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

Temperature Adjustment Line » Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

-

・Complete with energy-saving triple inverter!

・Outdoor installation, Splashproof type (IPX4)

・Max. ambient temperature: 45℃

・Min. ambient temperature: –20℃ (For the air-cooled type)

・Temperature stability: ±0.1℃ (When a load is stable)

・Space saving and lightweight: 280 kg (25 kW type)

・Compliant with UL Standards, CE-marking

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRSH | 5 to 35℃ | 10 kW 15 kW 20 kW 25 kW 28 kW | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water Deionized water Ethylene glycol aqueous solution (15%) |