There were 318 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Modular F.R.L./Pressure Control Equipment 25A-

Series Compatible with Secondary Batteries Series 25A- » ModularF.R.L./Pressure Control Equipment

-

∗1 Available as simple specials. Please contact your local sales representative for more details.

∗2 Standard products: Standard products are copper (Cu) and zinc (Zn) free.

| Series | Model | Specification |

|---|---|---|

| Modular F.R.L. Units | Simple Specials | |

| Air Filter Separator | 25A-AF-D | Air filter |

| Air Filter Separator | 25A-AFM-D | Mist separator |

| Air Filter Separator | 25A-AFD-D | Micro mist separator |

| Air Filter Separator | 25A-AF-A | Air filter |

| Air Filter Separator | 25A-AFM-A | Mist separator |

| Air Filter Separator | 25A-AFD-A | Micro mist separator |

| Regulator | 25A-AR-D | Regulator |

| Regulator | 25A-AR□K-D | Regulator with backflow function |

| Regulator | 25A-AW-D | Filter regulator |

| Regulator | 25A-AW□K-D | Filter regulator with backflow function |

| Regulator | 25A-AR-B | Regulator |

| Regulator | 25A-AR□□K-B | Regulator with backflow function |

| Regulator | 25A-AW-B | Filter regulator |

| Regulator | 25A-AW□□K-B | Filter regulator with backflow function |

| Regulator | 25A-AWM-D | Mist Separator Regulator |

| Regulator | 25A-AWD-D | Micro Mist Separator Regulator |

| Regulator | 25A-IR□-A | Precision regulator |

| Regulator | 25A-ITV1000, 2000, 3000 | Electro-pneumatic regulator |

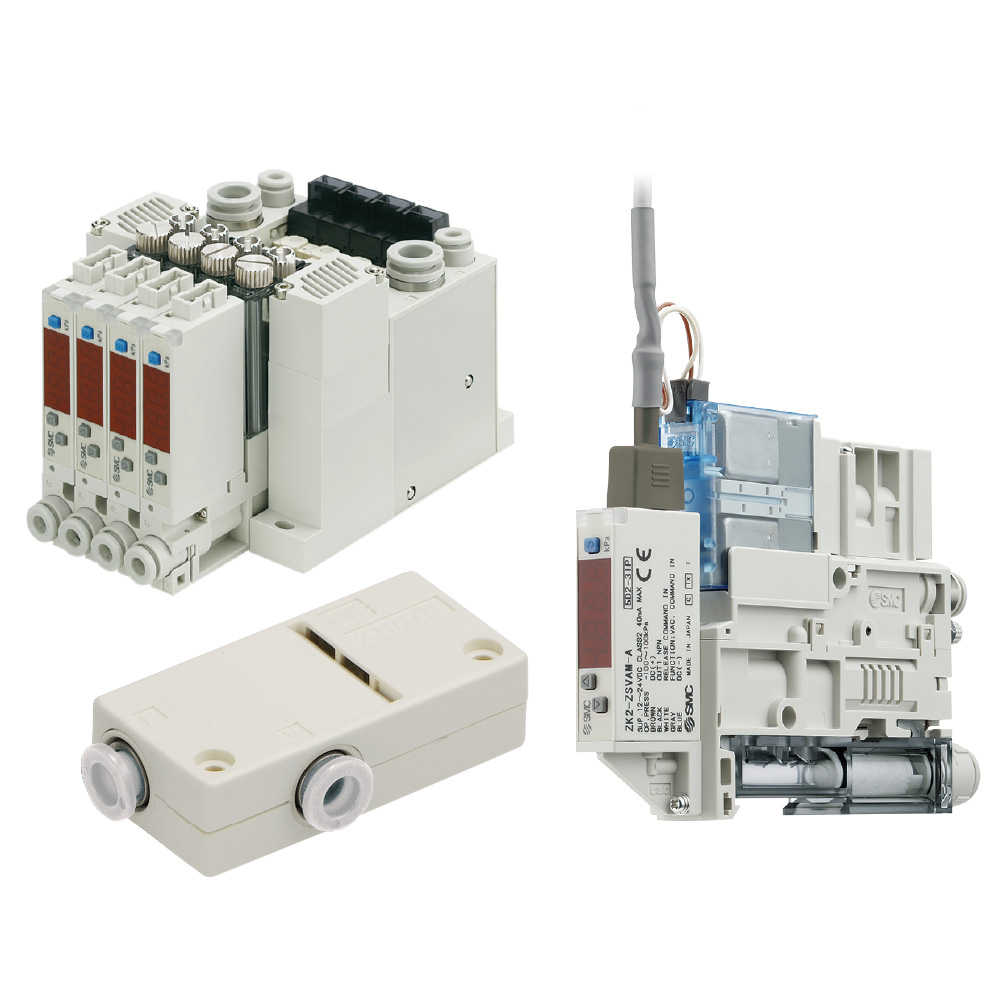

Vacuum Equipment 25A-

Series Compatible with Secondary Batteries Series 25A- » Vacuum Equipment

-

∗1 Standard products: Standard products are copper (Cu) and zinc (Zn) free.

Refer to the Web Catalog for details.

・Click here for Vacuum Ejector/Series ZH□□DA

・Click here for In-line Type Vacuum Ejector/Series ZU□□A

・Click here for Air Suction Filter/Series ZFC

・Click here for Vacuum Pad/Series ZP

・Click here for Adsorption Plate/Series SP

∗2 For the ZH (body ported) series, only the screw-in type uses copper.

One-touch connection type is copper-free as standard.

・Click here for Vacuum Ejector/Series ZH

| Series | Model | Specification |

|---|---|---|

| Vacuum Unit | 25A-ZK2□A(Vacuum unit) | Single unit only |

| Space Saving Vacuum Ejector | 25A-ZQ(Ejector unit) | Single unit/Manifold |

| Space Saving Vacuum Ejector | 25A-ZQ(Vacuum pump unit) | Single unit/Manifold |

| Space Saving Vacuum Ejector | ZH□□DA(Body ported)*1 | |

| Space Saving Vacuum Ejector | ZH(Body ported)*2 | |

| In-line Type Vacuum Ejector | ZU□□A(In-line type)*1 | |

| In-line Air Filter | ZFC(With One-touch fittings)*1 | |

| Air Suction Filter | ZFC*1 (With One-touch fittings, In-line type) | |

| Vacuum Pad | ZP*1 | Pad only |

| Vacuum Regulator | 25A-IRV | |

| Adsorption Plate | SP*1 |

Aluminum High Vacuum Angle Valve XLA/C/F/G

High Vacuum Equipment » High Vacuum Valves-

・Aluminum bodied

Uniform baking temperature

Lightweight, Compact

Minimal outgassing

Minimal contamination from heavy metals

・Bellows are replaceable.

Safety Instructions System Configuration/Role of Each Line and Component Series Variations Glossary Auto Switches Common Specifications Green Procurement (RoHS)

| Series | Actuation | Valve type | Shaft seal type | Application | Flange size |

|---|---|---|---|---|---|

| XLA-2 | Air operated | Single acting (N.C.) | Bellows seal | Dust free, Cleaned | 16 to 80 |

| XLAV-2 (With solenoid valve) | Air operated | Single acting (N.C.) | Bellows seal | Dust free, Cleaned | 16 to 80 |

| XLC-2 | Air operated | Double acting | Bellows seal | Dust free, Cleaned | 16 to 80 |

| XLF-2 | Air operated | Single acting (N.C.) | O-ring seal | High-speed operation, High operating cycles | 16 to 80 |

| XLFV-2 (With solenoid valve) | Air operated | Single acting (N.C.) | O-ring seal | High-speed operation, High operating cycles | 16 to 80 |

| XLG -2 | Air operated | Double acting | O-ring seal | High-speed operation, High operating cycles | 16 to 80 |

Peltier-Type Thermo-con/Rack Mount Type

HECR

Temperature Control Equipment » Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)-

・Good space utilization: Mountable in a 19-inch rack

Saves space by allowing multiple pieces of equipment to be mounted

together in a rack.

・Temperature stability: ±0.01℃ to 0.03℃

・Set temperature range: 10℃ to 60℃

・Cooling capacity: 200 W, 400 W, 510 W, 800 W, 1 kW, 1.2 kW

・Power consumption: 200 W, 300 W, 400 W

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method |

|---|---|---|---|---|

| HECR002-A | 10 to 60℃ | 200 W | ±0.01 to 0.03℃ | Peltier-type air-cooled |

| HECR004-A | 10 to 60℃ | 400 W | ±0.01 to 0.03℃ | Peltier-type air-cooled |

| HECR006-A | 10 to 60℃ | 510 W | ±0.01 to 0.03℃ | Peltier-type air-cooled |

| HECR006L-A | 10 to 60℃ | 510 W | ±0.01 to 0.03℃ | Peltier-type air-cooled |

| HECR008-A | 10 to 60℃ | 800 W | ±0.01 to 0.03℃ | Peltier-type air-cooled |

| HECR010-A | 10 to 60℃ | 1 kW | ±0.01 to 0.03℃ | Peltier-type air-cooled |

| HECR008-W | 10 to 60℃ | 800 W | ±0.01 to 0.03℃ | Peltier-type water-cooled |

| HECR012-W | 10 to 60℃ | 1.2 kW | ±0.01 to 0.03℃ | Peltier-type water-cooled |

EU F-Gas Regulation-compliant Refrigerated Thermo-chiller HRZ-F

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance Type & Inverter Type

-

・More effective energy-saving is achieved through use of a DC inverter compressor and an inverter pump.

・Energy saving

The inverter controls the number of motor rotations of the compressor and pump according to the load from the user’s application.

Power consumption: Max. 65% reduction

Facility water: Max. 67% reduction

・High performance

Temperature stability: ±0.1°C (When a load is stable)

Cooling time: Max. 46% reduction (SMC comparison)

・Refrigerant: R410A (HFC)/R448A (HFC/HFO)

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRZ-F | -20 to 40℃ 10 to 60℃ -20 to 90℃ | 2 kW, 4 kW, 8 kW, 10 kW | ±0.1℃ | Water-cooled refrigeration | Fluorinated fluids Ethylene glycol aqueous solution Tap water/Deionized water |

Thermo-chiller/Rack Mount Type HRR

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Rack Mount Type

-

・Operable without the need to remove the unit from the rack

Front access: Simple to control, service, and maintain with all filters and drainage accessible via the front panel

・Space saving: Multiple chillers can be mounted to a 19-inch rack.

・Cooling capacity: 1.1/1.2/1.8/2.4/3.0/5.1 kW (60 Hz)

・Temperature stability: ±0.1℃

・Global power supply:

Single-phase 100 VAC (50/60 Hz)/115 VAC (60 Hz)

Single-phase 200 to 230 VAC (50/60 Hz)

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRR | 5 to 35℃ 15 to 35℃ | 1.1 kW 1.2 kW 1.8 kW 2.4 kW 3.0 kW 5.1 kW | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water Ethylene glycol aqueous solution (15%) |

Thermo-chiller/Dual Channel Thermo-chiller for Lasers HRL

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Dual Channel Thermo chiller for Lasers

-

・Temperatures for 2 fluid channel systems can be controlled individually

by one chiller.

・Space saving, Reduced wiring

Footprint: 22% reduction

One power supply system for 2 channels

・Energy saving

Power consumption reduced by 30%

・Touch panel

・Power supply:

3-phase 200 VAC (50 Hz)

3-phase 200 to 230 VAC (60 Hz)

3-phase 380 to 415 VAC (50/60 Hz)

3-phase 460 to 480 VAC (60 Hz)

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRL100 | CH1: 15 to 35℃ CH2: 10 to 40℃ | CH1:9 kw, CH2: 1.0 kW (Max. 5.0 kW) | CH1:±0.1, CH2:±0.5 | Air-cooled refrigeration, Water-cooled refrigeration | Tap water, Deionized water |

| HRL200 | CH1: 15 to 35℃ CH2: 10 to 40℃ | CH1:9 kw, CH2: 1.0 kW (Max. 5.0 kW) | CH1:±0.1, CH2:±0.5 | Air-cooled refrigeration, Water-cooled refrigeration | Tap water, Deionized water |

| HRL300 | CH1: 15 to 35℃ CH2: 10 to 40℃ | CH1:26 kw, CH2: 1.0 kW (Max. 5.0 kW) | CH1:±0.1, CH2:±0.5 | Air-cooled refrigeration | Tap water, Deionized water |

| HRL400 | CH1: 15 to 35℃ CH2: 10 to 40℃ | CH1:26 kw, CH2: 1.0 kW (Max. 5.0 kW) | CH1:±0.1, CH2:±0.5 | Air-cooled refrigeration | Tap water, Deionized water |

Thermo-chiller/Inverter Type HRSH090

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

-

・Power consumption reduced by 53%

Complete with energy-saving triple inverter!

・Cooling capacity: 9.5 kW (Air-cooled), 11.0 kW (Water-cooled)

・Temperature stability: ±0.1°C

・Set temperature range: 5°C to 40°C

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRSH090 | 5 to 40℃ | 9.5 kW | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water Deionized water Ethylene glycol aqueous solution (15%) |

Valve for Water and Chemical Base Fluids (2/3-Port Air Operated Valve) VCC

Process Valves » Valves for Water and Chemical Base Fluids

-

・Applicable for 2 liquid paints (VCC12D)

PTFE diaphragm structure = Elimination of sliding parts

Less paint adhesion

・Mountable on a robot arm (Space saving, Lightweight)

2 valves per station (30 mm pitch)

2/3-port valves mixed mounting

Resin manifold block

| Series | Orifice diameter | Fluid |

|---|---|---|

| VCC | φ3.8 | Water/chemical-based paint, Ink, Cleaning fluid (Water, Butyl acetate), Air |

Direct Operated/Pilot Operated 2-Port Solenoid Valve JSX/JSX□

Process Valves » 2/3 Port Solenoid Valves/Air Operated Valves-

· A pilot operated steam type (JSXP series) has been added. New

· Improved environmental resistance due to the stainless steel coil cover

[IP67 enclosure/NEMA4X∗] ∗ IP65 for models with a DIN terminal

·Space saving

Compact: Valve volume reduced by 25%*, Lightweight: Weight reduced

by 30%*

* Compared with the existing model

·Energy saving

Coil force: 10% increase*, Power consumption: 14% reduction*

* Compared with the existing model

·360° lead wire insertion and removal is possible.

·Improved weather resistance in outdoor environments

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics

Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics

Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List

Green Procurement (RoHS)

| Series | Type | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|---|

| JSX | Direct operated | N.C/N.O. | 1/8, 1/4, 3/8 | 1.6 to 7.1 |

| JSX□□U | Direct operated high flow/ power saving type | N.C. | 1/8, 1/4, 3/8 | 2.4 to 7.1 |

| JSX□□V | Direct operated vacuum type | N.C. | 1/8, 1/4, 3/8 | 1.6 to 7.1 |

| JSX□□H | Direct operated high pressure type | N.C. | 1/4, 3/8 | 3.2 |

| JSX□□S | Direct operated steam type | N.C. | 1/4, 3/8 | 1.6,7.1 |

| JSXM | Direct operated modular mounting type | N.C. | 1/8,1/4,3/8,1/2 | 3.2,4 |

| JSXD | Pilot operated | N.C./N.O. | 1/4,3/8,1/2,3/4,1, 1 1/4,1 1/2,2,32A,40A,50A | 10 to 50 |

| JSXP | Steam type | N.C. | 3/8,1/2,3/4,1,

1 1/4, 1 1/2,2,32A,40A,50A | 15 to 50 |

| JSXZ | Zero differential pressure type pilot operated | N.C. | 1/4,3/8,1/2,3/8,1/2,3/4,1 | 10 to 25 |