There were 1,109 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Stainless Steel High Vacuum Angle/In-line Valve XM/XY

High Vacuum Equipment » High Vacuum ValvesEquipment for the Semiconductor Industries » Exhaust Line

Equipment for the Semiconductor Industries » N2 Gas/Air Supply Line

-

・The precision casting, unified composition prevents the accumulation of gas.

・The XM series is interchangeable with the XL series aluminum high vacuum angle valve.

Note) Size 16 is not available for the in-line type.

Safety Instructions System Configuration/Role of Each Line and Component Series Variations Glossary Auto Switches Common Specifications Green Procurement (RoHS)

| Series | Actuation | Shaft seal type | Valve type | Material | Flange size |

|---|---|---|---|---|---|

| XMA/XYA | Air operated | Bellows seal | Single acting (N.C.) | Body : SCS13 (Equivalent to stainless steel 304) Bellows : Stainless steel 316L | 16 to 80 Note) |

| XMC/XYC | Air operated | Bellows seal | Double acting | Body : SCS13 (Eequivalent to stainless steel 304) Bellows : Stainless steel 316L | 16 to 80 Note) |

| XMD/XYD | Air operated | Bellows/O-ring seal | Single acting (N.C.) | Body : SCS13 (Equivalent to stainless steel 304) Bellows : Stainless steel 316L | 25 to 80 |

| XMH/XYH | Manual | Bellows seal | Manual | Body : SCS13 (Equivalent to stainless steel 304) Bellows : Stainless steel 316L | 16 to 50 Note) |

Check Valve/Vacuum Generator/Flow Switch AP

Process Gas Equipment AP Tech » Process Gas EquipmentEquipment for the Semiconductor Industries » N2 Gas/Air Supply Line

-

[Check valve]

・Fluid backflow is prevented by back pressure.

・Unique design with only one moving part in the gas stream, an O-ring

・Springless structure suppresses particle generation by vibration or chattering and pressure fluctuations on the downstream side

[Vacuum generator]

・Vacuum generation equipment

・Applicable to the exhaustion of unnecessary gas remaining inside the piping during gas cylinder replacement

[Flow switch]

・Detects excess flow above a given flow rate caused by pipe breakage, etc.

Safety Instructions Process Gas Equipment/Common Precautions Series Variations Valve and Regulator Recommendations Technical Data/Glossary of Terms Green Procurement (RoHS)

| Series | Type | Body material |

|---|---|---|

| AP | Check Valve | 316L SS secondary remelt |

| AP | Vacuum Generators | 316L SS secondary remelt |

| AP | Flow Switches | 316L SS secondary remelt |

Peltier-Type Thermoelectric Bath HEB

Temperature Control Equipment » Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)Equipment for the Semiconductor Industries (Temperature Adjustment Line) » Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

Temperature Adjustment Line » Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

-

・High-precision temperature control bath that uses a Peltier device

・Compact and low noise

・Minimal up-down temperature distribution by a unique agitation method

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HEB | −15 to 60℃ | 140 W, 280 W | 0.01℃ | Round type Peltier-type water-cooled | Tap water, Fluorinated fluid |

Thermo-chiller/Standard Type HRS100/150

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

Temperature Adjustment Line » Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

Equipment for the Semiconductor Industries (Temperature Adjustment Line) » Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

-

・No heater is required, as the circulating fluid is heated using only the heat exhausted by the refrigerating circuit.

・Compatible with power supplies in Europe, Asia, Oceania, North, Central, and South America

・Low-noise design: 70 dB (A)

・Outdoor installation: IPX4

・Compact, Space saving

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRS100 HRS150 | 5 to 35℃ | 9.5 kW 14.5 kW (60 Hz) | ±1.0℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water Deionized water Ethylene glycol aqueous solution (15%) |

Low Profile 2/3-Port Solenoid Valve SX90/090

Process Valves » Compact 2/3 Port Solenoid Valves-

・Compact

Overall length: Approx. 38 mm (2-port), 54 mm (3-port)

Valve width/height: 10 mm

Weight: 10 g (2-port), 20 g (3-port)

・Large flow rate

C [dm3/(s·bar)]: 0.25 (2-port), 0.5 (3-port)

Flow rate [L/min (ANR)]: 45 (2-port), 90 (3-port) (At 0.2 MPa)

| Series | Valve construction | C[dm3/(s·bar)] | Flow rate [L/min (ANR)] at 0.2 MPa | Type of actuation |

|---|---|---|---|---|

| SX91 | 2-port direct operated poppet valve | 0.25 | 45 | Normally closed |

| SX92 | 2-port direct operated poppet valve | 0.12 | 22 | Universal |

| SX090 | 3-port direct operated poppet valve | 0.5 | 90 | Universal |

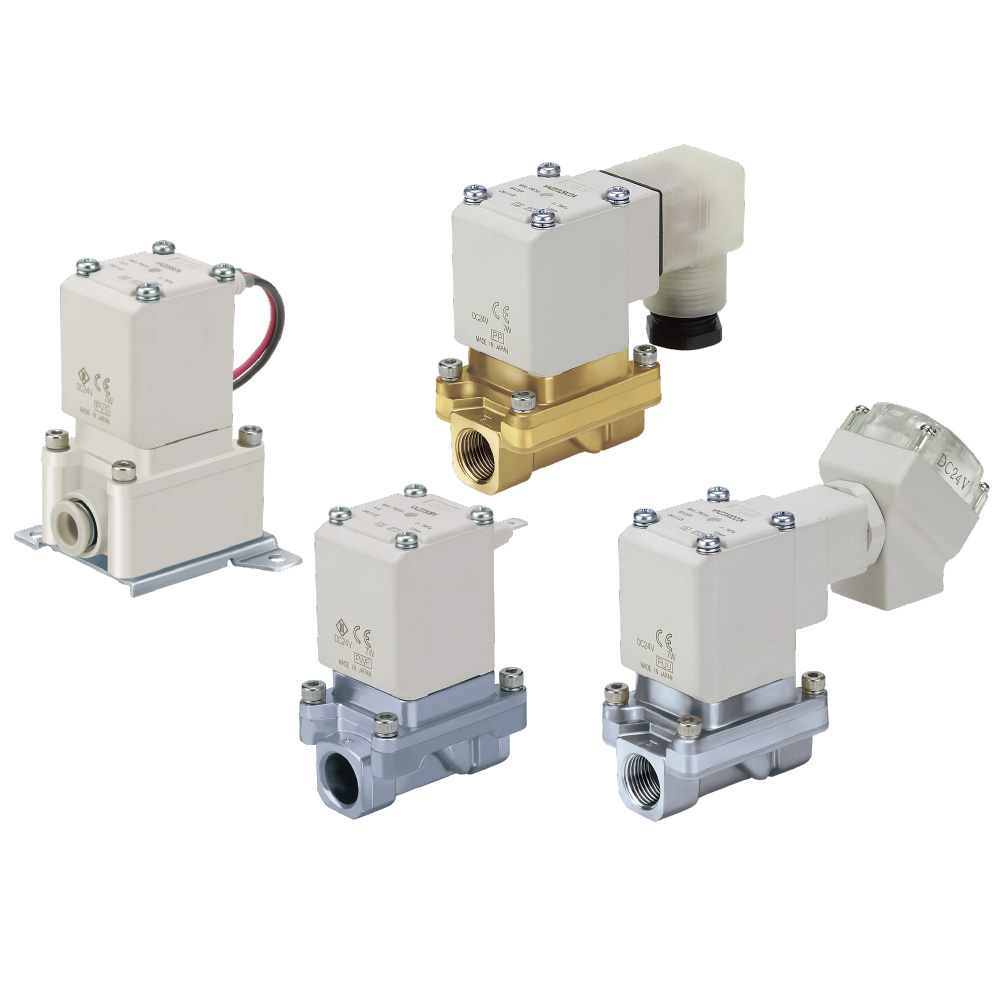

Zero Differential Pressure Type/Pilot Operated 2 Port Solenoid Valve (2 Way Valve) VXZ

Process Valves » 2/3 Port Solenoid Valves/Air Operated Valves-

・For air, water, oil, heated water, high-temperature oil

・Body materials: Aluminum, Resin, C37, Stainless steel

・A type with One-touch fittings (Resin body) is available.

・IP65

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions

Model Selection/Flow Rate Characteristics

Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List

Green Procurement (RoHS)

Model Selection/Flow Rate Characteristics

Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List

Green Procurement (RoHS)

| Series | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|

| VXZ | N.C./N.O. | φ10, φ12,φ3/8'' 1/4 to 1 | 10 to 25 |

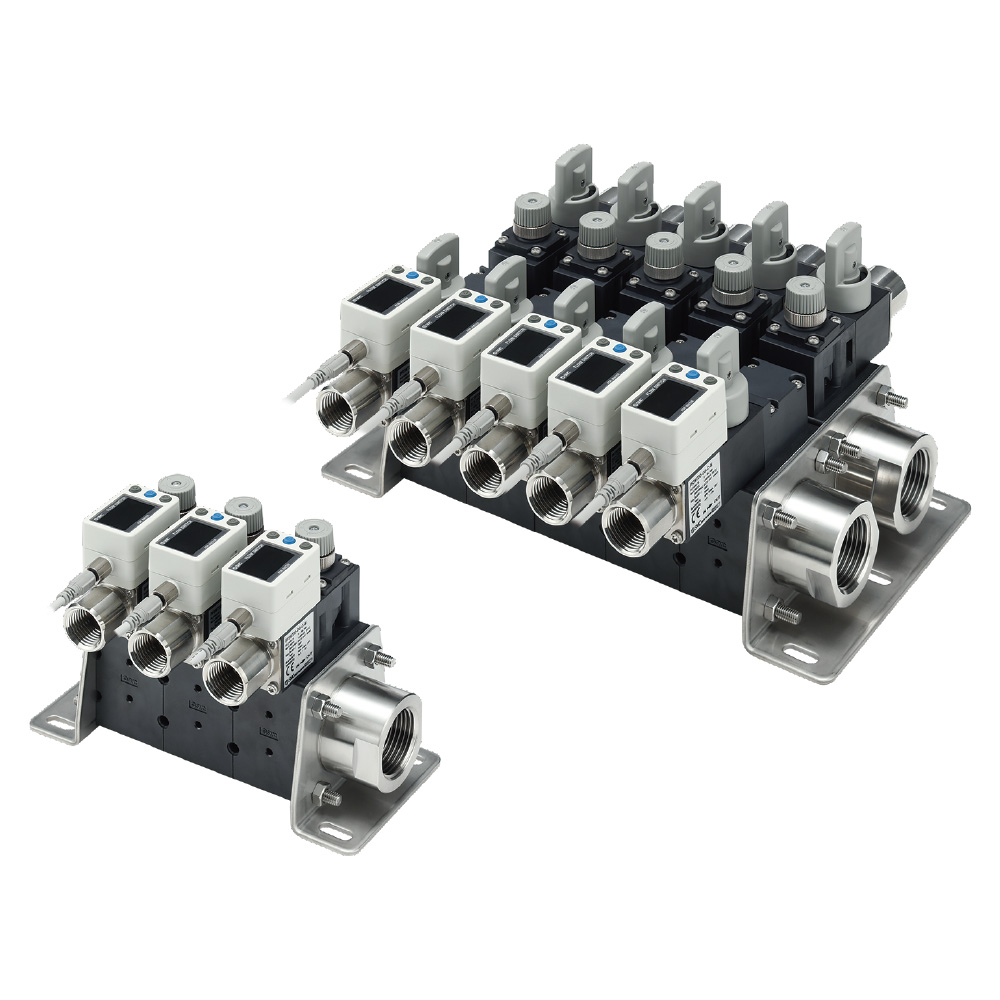

Digital Flow Switch Manifold for Water PF3WB/C/S/R

Switches/Sensors/Controller » Electronic Flow Switches/SensorsIO-Link Compatible Products » Digital Flow Switch

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: IO-Link Compatible Products

Equipment for the Semiconductor Industries » Cooling Water Line

-

・Applicable fluid: Water, Ethylene glycol aqueous solution

・Space saving

Footprint Max. 85% reduction

Weight Max. 65% reduction

・Needs no piping: Work-hour for installation reduced by up to 45%

・IO-Link compatible

・3-color/2-screen display

・Fluid temperature: 0 to 90℃

▶IO-Link Master

Safety Instructions Pressure Switches/Flow Switches/Precautions Flow Switch Series Variations

Green Procurement (RoHS) IO-Link Master

Green Procurement (RoHS) IO-Link Master

| Series | Rated flow range (L/min) |

|---|---|

| PF3WB Integrated type (Basic type) | 0.5 to 4 2 to 16 5 to 40 |

| PF3WC Integrated type (Straight type) | 0.5 to 4 2 to 16 5 to 40 |

| PF3WS Remote type (Supply type) | 0.5 to 4 2 to 16 5 to 40 |

| PF3WR Remote type (Return type) | 0.5 to 4 2 to 16 5 to 40 |

Pressure Sensor/Switch for General Fluids PSE57□

Switches/Sensors/Controller » Electronic Pressure Switches/Sensors (Remote Type)Equipment for the Semiconductor Industries » Cooling Water Line

-

・PSE Sensor Set Up Tool PSE-ST has been added. [New]

・Switch output specification

・IO-Link compatible

・Withstand voltage: 500 VAC

・Enclosure: IP65

・Materials of parts in contact with fluid

Piping port: C3604 + Nickel plating

Pressure sensor: Al2O3 (Alumina 96%)

O-ring: FKM + Grease (PSE570/573/574)

Square ring: FKM (PSE575/576/577)

Safety Instructions Pressure Switches/Flow Switches/Precautions

Pressure Switch Series Variations/Application Example Glossary of Terms/Technical Information

Green Procurement (RoHS)

Pressure Switch Series Variations/Application Example Glossary of Terms/Technical Information

Green Procurement (RoHS)

| Series | Type | Rated pressure range | Proof pressure |

|---|---|---|---|

| PSE570 | Positive pressure | 0 to 1 MPa | 3.0 MPa |

| PSE573 | Compound pressure | -100 to 100 kPa | 600 kPa |

| PSE574 | Positive pressure | 0 to 500 kPa | 1.5 MPa |

| PSE575 | Positive pressure | 0 to 2 MPa | 5.0 MPa |

| PSE576 | Positive pressure | 0 to 5 MPa | 12.5 MPa |

| PSE577 | Positive pressure | 0 to 10 MPa | 30 MPa |

Pressure Gauge with Switch GP46

Silencers/Exhaust Cleaners/Blow Guns/Pressure Gauges » Pressure GaugesSwitches/Sensors/Controller » Mechanical Pressure Switches

-

・A pressure switch function has been added to the gauge.

Safety Instructions Series Variations Procedures for Setting and Assembling (P.1298) Specific Product Precautions (P.1299) Green Procurement (RoHS)

| Series | Size (O.D.) | Connection thread |

|---|---|---|

| GP46 | φ42.5 | R1/8,1/4 |

Exhaust Flow Control Valve with Indicator AS-DPX00042

Flow Control Equipment » Related Equipment-

・Contributes to reduced setting errors and work hours by managing flow rate figures (indicator)

・Integrated restrictor and silencer

Reduced assembly time and number of components

・The speed can be adjusted on the valve side

| Type | Series | Connection thread |

|---|---|---|

| Exhaust flow control valve with indicator | AS-DPX00042 | R1/4 |