There were 1,029 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Dust-tight/Water-jet-proof (IP69K Equivalent) Electric Actuator/Rod Type HF2A-LEY

Electric Actuators/Cylinders » Rod Type/Guide Rod Type-

・Enclosure: IP69K equivalent

Smooth design for less residual liquid accumulation

External parts: Stainless steel 304

Scraper, Static seal: US FDA compliant material (Blue)

Grease: NSF-H1 grade

・Equipment for the food manufacturing industry HF2A- series

・Lubricants or rust proof agents are not used for the external parts.

Otherwise, lubricants or rust proof agents for the food machinery are

being used.

・US FDA compliant materials are used.

・Work load: Max. 80 kg∗ ∗ Size 63, Lead C

・Stroke: Max. 800 mm∗ ∗ Size 63

* IP69K is the degree of protection against dust and high-temperature/

high-pressure water washdown specified in DIN 40050-9 and

currently specified in ISO 20653 and JIS D 5020.

| Specification | Model | Stroke (mm) | Pushing force (N) | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| AC servo motor | HF2A-LEY25 | 50 to 400 | Max. 485 | Max. 900 | 12,20 |

| AC servo motor | HF2A-LEY32 | 50 to 500 | Max. 588 | Max. 1200 | 6,10 |

| AC servo motor | HF2A-LEY63 | 50 to 800 | Max. 1910 | Max. 1000 | 3,5 |

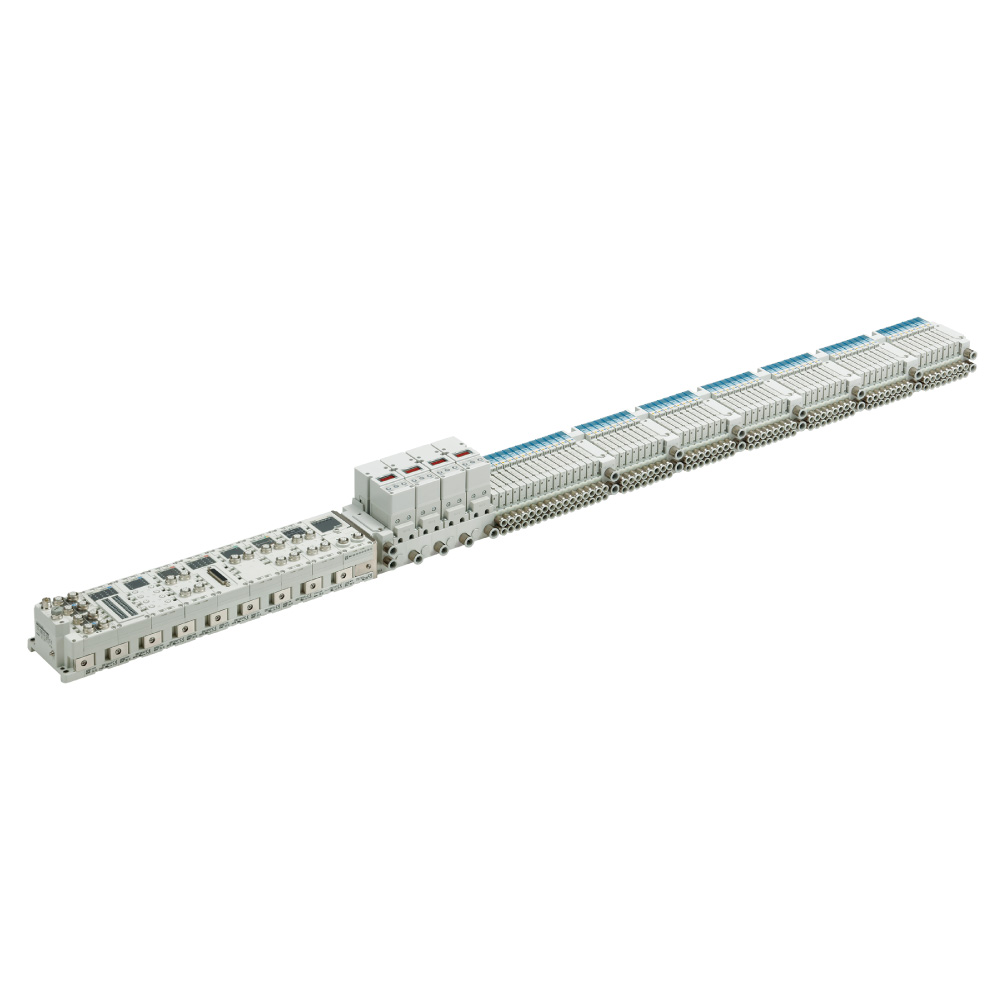

Electro-pneumatic Regulator Integrated Type 64-station Compatible Manifold Plug-in Compact 5-Port Solenoid Valve JSY3000-P

Directional Control Valves » Pilot Operated 4/5 Port Solenoid ValvesIndustrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: PROFINET Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherNet/IP Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherCAT Compatible Products

-

・Solenoid valves and electro-pneumatic regulators can be connected to

the same manifold.

Valve stations/Number of outputs: For 4 to 64 stations∗/128 points

∗ Stations are only available in multiples of 4.

Electro-pneumatic regulator stations: 1 to 4 stations

I/O unit stations: Max. 8 stations

・Equipment integration allows for the centralized management of control

and wiring as well as reduced wiring

Reduced wiring, Reduced number of SI units, Reduced wiring work,

Compact

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Enclosure | Communication protocol | Applicable devices |

|---|---|---|---|

| JSY3000-P | IP65 | PROFINET EtherNet/IP™ EtherCAT | SI unit: EX600 Valve: JSY3000 Electro-pneumatic regulator: ITV2340 |

[Low GWP Refrigerant Chiller] Refrigerated Thermo-chiller HRZF

Temperature Control Equipment » Chiller Compliant RegulationsEquipment for the Semiconductor Industries (Temperature Adjustment Line) » Chiller Compliant Regulations

Temperature Adjustment Line » Chiller Compliant Regulations

-

· Low GWP refrigerant chiller

GWP:146∗ ∗ Regulation (EU) 2024/573, AIM Act 40 CFR Part 84

EU refrigerant regulations: GWP150 or more

US refrigerant regulations: GWP700 or more

California, US refrigerant regulations: GWP750 or more

· Environmentally friendly R454C as refrigerant (Not available for air

transport)

· More effective energy-saving is achieved through use of a DC inverter

compressor and an inverter pump.

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRZF010 | -20〜90℃ | 10kW | ±0.1℃ | Water-cooled refrigeration | Fluorinated fluids, 60% ethylene glycol aqueous solution |

Air Management System 25A-AMS20/30/40/60

Series Compatible with Secondary Batteries Series 25A- » Air Management System-

・Air consumption: Max. 62% reduction

Monitors the machine standby conditions (when production stops) and

automatically decreases the pressure.

Reduces unnecessary air consumption

・Compatible with OPC UA

Direct connection enables data communications.

・Compatible with wireless systems

Communication cables not required

High security thanks to unique encryption

Communication distance: Max. 100 m

・IO-Link compatible

| Series | Size | Port size | Flow capacity [L/min] | Communication protocol | Output data |

|---|---|---|---|---|---|

| Electro-Pneumatic Regulator Type

25A-AMS20A/30A/40A/60A | 20 30 40 60 | 1/8 1/4 3/8 1/2 3/4 1 | 5 to 500 10 to 1000 20 to 2000 40 to 4000 | PROFINET EtherNet/IP™ OPC UA EtherCAT | Instantaneous flow Accumulated flow Pressure Fluid temperature Various sensor information transmitted via IO-Link Diagnosis |

| Regulator Type

25A-AMS20B/30B/40B/60B | 20 30 40 60 | 1/8 1/4 3/8 1/2 3/4 1 | 5 to 500 10 to 1000 20 to 2000 40 to 4000 | PROFINET EtherNet/IP™ OPC UA EtherCAT | Instantaneous flow Accumulated flow Pressure Fluid temperature Various sensor information transmitted via IO-Link Diagnosis |

Stainless Steel Speed Controller (Max. operating temperature: 150°C) In-line Type ASG

Flow Control Equipment » Speed Controllers Special Environments-

· Improved corrosion/heat resistance with the all stainless steel exterior

Possible for use in environments such as high temperature, water

splashing, and where copper and zinc cannot be used

· Material: Stainless steel 316 (External metal parts)∗, FKM (Seal)

∗ Stainless steel 304 is used as the material for parts other than body A.

· Max. operating temperature: 150°C

· NSF H1 grease

| Type | Series | Port size on the cylinder side | Applicable tubing O.D. Metric size | Applicable tubing O.D. Inch size |

|---|---|---|---|---|

| In-line type Stainless steel type | ASG1002 to ASG4002 | - | φ4 to φ12 | φ5/32” to φ1/2” |

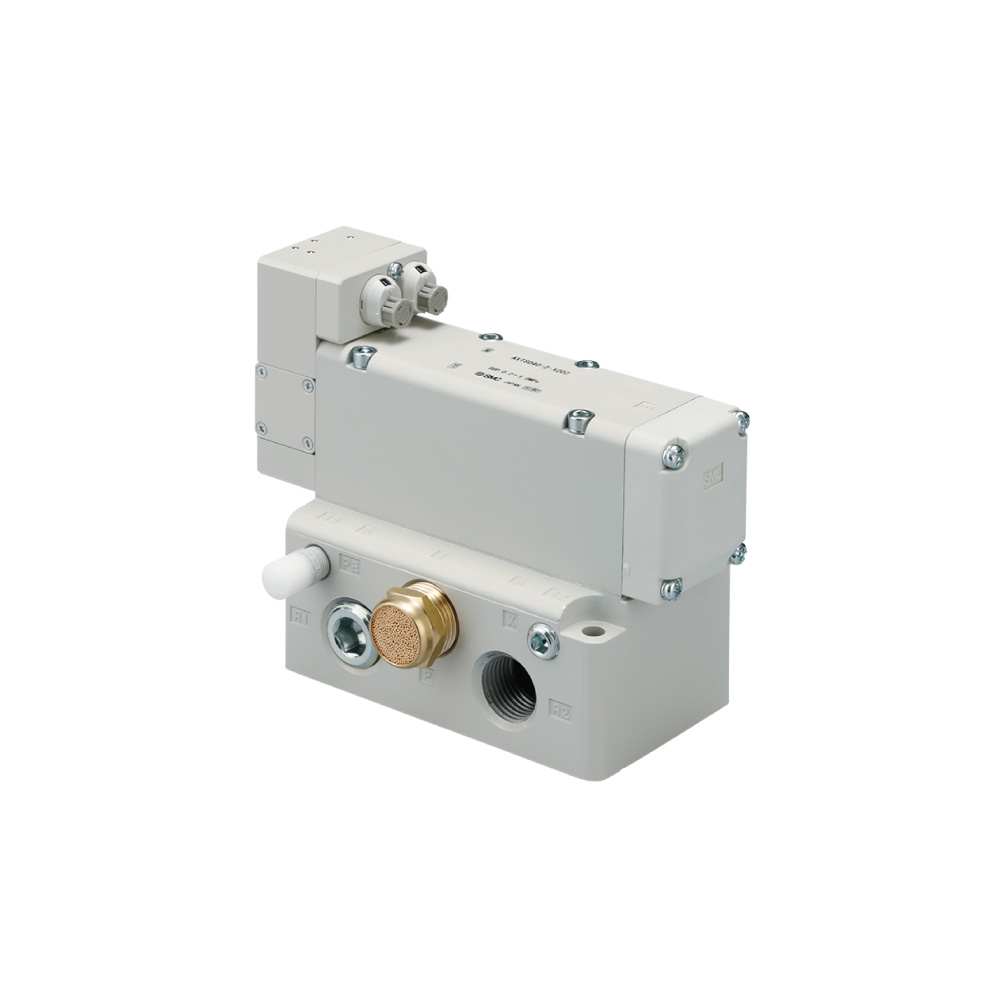

Pulse Blow Valve AXTS040-X202

Process Valves » Compact 2/3 Port Solenoid Valves/Air Operated ValvesAir Blowing Equipment » Air Blowing Equipment

-

・The peak pressure of repeatedly colliding air permits efficient blowing.

・CO2 emissions (Air consumption): 50% reduction

・Control for pulse generation is not required.

Pulse blow can be used by simply supplying air.

・Built-in pilot valve construction allows for stable blowing.

| Series | Valve construction | Type of actuation | Frequency adjustment range |

|---|---|---|---|

| AXTS040□-X202 | Metal seal | Internal pilot | 1 to 12 Hz |

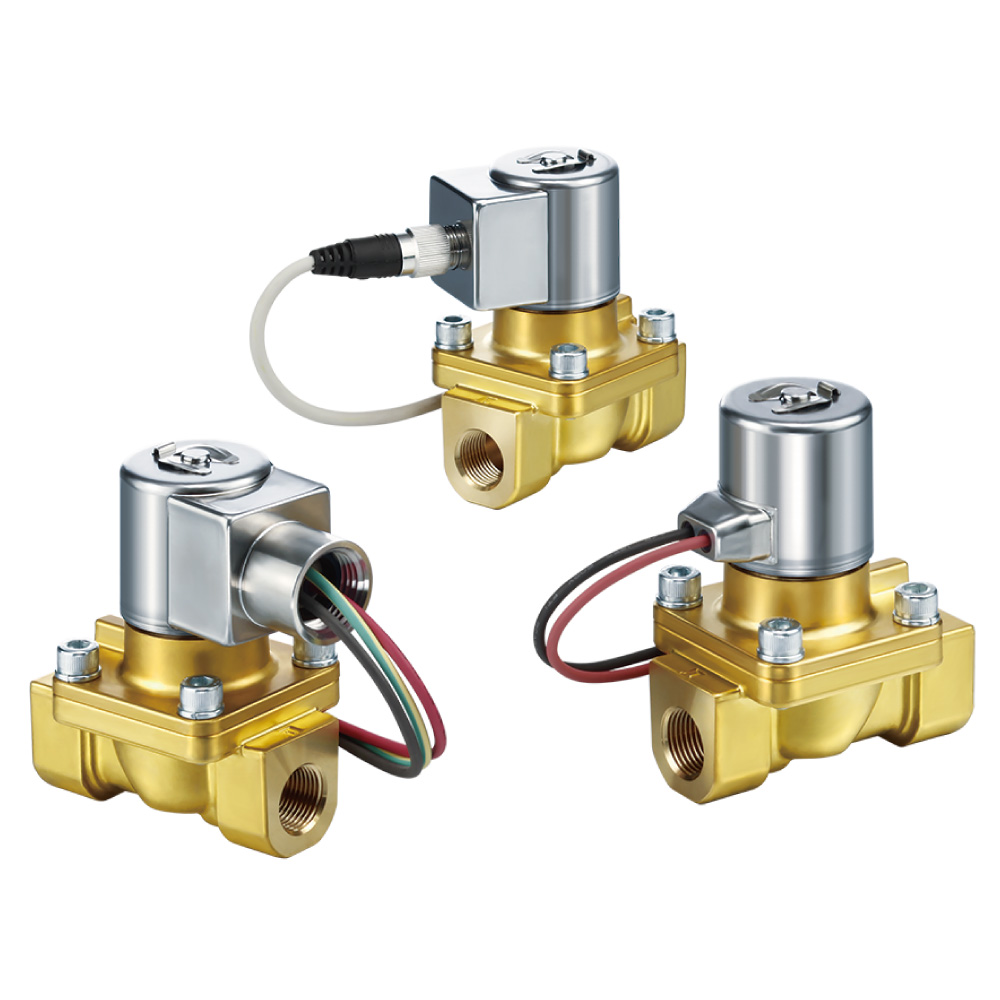

Pilot Operated 2-Port Solenoid Valve JSXH-X1

Process Valves » 2/3 Port Solenoid Valves/Air Operated Valves-

・Max. operating pressure differential: 4.0 MPa

Application examples: Blow molding, Laser processing machines,

Nitrogen filling unit

・Fluid: Compressed air, Nitrogen, Argon, Oxygen∗

∗ When using oxygen, please refer to "Fluid Supply."

・Improved environmental resistance

Dustproof/waterproof IP67 structure (IP65 for the DIN terminal)

With a stainless steel coil cover

・Low particle generation

・Oil-free

・Easy maintenance

The coil can be replaced by simply removing the clip.

・Power saving (Power consumption: 6 W)

Safety Instructions 2 Port Solenoid Valves for Fluid Control Precautions Model Selection/Flow Rate Characteristics Series Variations/Selection Procedure/Solenoid Valves List/Air Operated Valves List Green Procurement (RoHS)

| Series | Type | Valve type | Port size | Orifice diameter (mmø) |

|---|---|---|---|---|

| JSXH-X1 | Pilot operated | N.C. | 3/8,1/2 | 16 |

Electric Actuator/Slider Type (Improved Dust and Water-jet Resistance) LEFSW

Electric Actuators/Cylinders » Environment-

・A dust-tight and water-jet-resistant (IP65 equivalent*1) slider type product

Newly developed special wear-resistant seal band

A special wear-resistant seal band is mounted on the bottom to prevent

dust and water from entering the inside of the product.

・With internal battery-less absolute encoder

Restart from the last stop position is possible after recovery of the power

supply.

Reduced maintenance (No need to manage or replace batteries)

・Work load: Max. 65 kg

・Stroke: Max. 1200 mm (Size 40)

∗1 IP65 Equivalence

The dust-tight and water-jet-resistant performance of this product's

motor part is equivalent to IP65. However, since the actuator part has

an opening, an IP65 rating for the actuator body cannot be guaranteed.

| Specification | Model | Stroke (mm) | Work load (kg) Horizontal | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Battery-less absolute (Step motor 24 VDC) | LEFSW16E | 50 to 500 | Max. 15 | Max. 700 | 5,10 |

| Battery-less absolute (Step motor 24 VDC) | LEFSW25E | 50 to 800 | Max. 30 | Max. 750 | 6,12,20 |

| Battery-less absolute (Step motor 24 VDC) | LEFSW32E | 50 to 1000 | Max. 50 | Max. 850 | 8,16,24 |

| Battery-less absolute (Step motor 24 VDC) | LEFSW40E | 150 to 1200 | Max. 65 | Max. 800 | 10,20,30 |

Low-Pressure / High-Precision Type 5.0 MPa Maximum Supply Pressure High Pressure Electro-Pneumatic Regulator ITVX2030-X10

Pressure Control Equipment » Electro-Pneumatic Regulators-

・Improved accuracy at 1 MPa or less

Repeatability: ±0.5% F.S. or less

Pressure stability: 0.5% F.S. or less

・Max. supply pressure: 5.0 MPa

・Set pressure range: 0.01 to 3.0 MPa

・Max. flow rate: 3000 L/min (ANR)

・Fluid: Air, N2, O2, Ar

・Wetted parts: Fluorine grease

Safety Instructions F.R.L. Units/Precautions Series Variations/Pressure Control Equipment

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Port size | Set pressure [MPa] |

|---|---|---|

| ITVX2030-X10 | 3/8 | 0.01 to 3.0 |

Modular Type Water Separator AFG-D

Modular F.R.L. Units » Air Flters/Mist Separators/Micro Mist Separators-

· The no filter element design achieves a large flow and

maintenance free construction.

· Water droplets are removed by centrifugal force.

(Water droplet removal ratio: 99%)

Air containing water droplets is rotated to remove them

by centrifugal force.

· Modular Design with Uniform Body Style

| Series | Port size | Water droplet removal rat |

|---|---|---|

| AFG20 to 40-D | 1/8,1/4,3/8,1/2,3/4 | 99% |