There were 1,029 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

[Low GWP Refrigerant Chiller] Thermo-chiller Standard Type HRSF

Temperature Control Equipment » Chiller Compliant RegulationsEquipment for the Semiconductor Industries (Temperature Adjustment Line) » Chiller Compliant Regulations

Temperature Adjustment Line » Chiller Compliant Regulations

-

・Low GWP Refrigerant Chiller

GWP: 146∗ ∗ Regulation (EU) 2024/573, AIM Act 40 CFR Part 84

EU refrigerant regulations: GWP150 or more

US refrigerant regulations: GWP700 or more

California, US refrigerant regulations: GWP750 or more

・Environmentally friendly R454C as refrigerant (Not available for air

transport)

・No heater is required, as the circulating fluid is heated using only the heat

exhausted by the refrigerating circuit.

・Compatible with power supplies in Europe, Asia, Oceania, and North,

Central, and South America

・3-phase 400 VAC Low-noise design 70 dB(A)

・Outdoor installation IPX4

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRSF012 to 060 | 5 to 40℃ | 1.3 kW, 1.9 kW, 2.4 kW, 3.2 kW, 5.9 kW (60 Hz) | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water 15 to 40% Ethylene glycol aqueous solution Deionized water |

[Low GWP Refrigerant Chiller] Thermo-chiller/Dual Channel Thermo-chiller for Lasers HRLF

Temperature Control Equipment » Chiller Compliant RegulationsEquipment for the Semiconductor Industries (Temperature Adjustment Line) » Chiller Compliant Regulations

Temperature Adjustment Line » Chiller Compliant Regulations

-

・Low GWP refrigerant chiller

GWP: 146∗ ∗ Regulation (EU) 2024/573, AIM Act 40 CFR Part 84

EU refrigerant regulations: GWP150 or more

US refrigerant regulations: GWP700 or more

California, US refrigerant regulations: GWP750 or more

・Environmentally friendly R454C as refrigerant (Not available for air

transport)

・Temperatures for 2 fluid channel systems can be controlled individually

by one chiller.

・Space saving, Reduced wiring

・Touch panel

Numeric keypad inputs

Notice for alarms and maintenance

Temperature waveform can be displayed.

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRLF200-A-40 | CH1:5 to 35℃ CH2:10 to 40℃ | CH1: 19 kW CH2: 1.0 kW (Max. 3.0 kW) | CH1: ±0.1℃ CH2: ±0.5℃ | Air-cooled refrigeration | Tap water, Deionized water |

| HRLF200-W-40 | CH1:5 to 35℃ CH2:10 to 40℃ | CH1: 21.5 kW CH2: 1.0 kW (Max. 3.0 kW) | CH1: ±0.1℃ CH2: ±0.5℃ | Water-cooled refrigeration | Tap water, Deionized water |

Battery-less Absolute Encoder Type

[Compatible with Manifold Controller]

Electric Actuator/Guide Rod Type LE2YG□H

Electric Actuators/Cylinders » Battery-less Absolute Encoder TypeElectric Actuators/Cylinders » Rod Type/Guide Rod Type

Electric Actuators/Cylinders » Manifold Controller/Manifold Controller Compatible Electric Actuator

-

· Guide Rod Type LE2YG□H Series has been added. [New]

· Compatible with manifold controller

Up to 16 axes can be connected

· Annual CO2 emissions reduced by up to 38% through motor control

optimization (SMC comparison)

8.7 kg-CO2e/year (14.1)

∗ The numerical values vary depending on the operating conditions.

· Battery-less absolute encoder type

Restart from the last stop position is possible.

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions Green Procurement (RoHS)

| Specification | Model | Stroke (mm) | Work load (kg) Horizontal | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Battery-less absolute (Step motor 24 VDC) | LE2YG16□H | 30 to 200 | Max. 40 | Max. 700 | 2.5,5,10 |

| Battery-less absolute (Step motor 24 VDC) | LE2YG25□H | 30 to 300 | Max. 70 | Max. 900 | 3,6,12,20 |

| Battery-less absolute (Step motor 24 VDC) | LE2YG32□H | 30 to 300 | Max. 100 | Max. 900 | 4,8,16,24 |

Battery-less Absolute Encoder Type

[Compatible with Manifold Controller]

Electric Actuator/Slider Type Belt Drive LE2FB□H

Electric Actuators/Cylinders » Manifold Controller/Manifold Controller Compatible Electric Actuator-

· Slider Type Belt Drive LE2FB□H Series has been added. [New]

· Compatible with manifold controller

Up to 16 axes can be connected

· Annual CO2 emissions reduced by up to 38% through motor control

optimization (SMC comparison)

8.7 kg-CO2e/year (14.1)

∗ The numerical values vary depending on the operating conditions.

· Battery-less absolute encoder type

Restart from the last stop position is possible.

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions Green Procurement (RoHS)

| Specification | Model | Stroke (mm) | Work load (kg) Horizontal | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Battery-less absolute (Step motor 24 VDC) | LE2FB16□H | 300 to 1200 | Max. 1 | Max. 1300 | 48 |

| Battery-less absolute (Step motor 24 VDC) | LE2FB25□H | 300 to 2200 | Max. 10 | Max. 1600 | 48 |

| Battery-less absolute (Step motor 24 VDC) | LE2FB32□H | 300 to 2600 | Max. 19 | Max. 1700 | 48 |

For liquids Clamp-on Type Flow Sensor PFUW

Switches/Sensors/Controller » Clamp-on Type Flow Sensor-

・Benefit from the eight “zeros” with clamp mounting!

Zero piping work

Zero leakage

Zero clogging

Zero pressure loss

Zero fluid contact

Zero fluid contact parts material concerns

Zero foreign matter entry into piping

Rated flow rate range from zero L/min

・“Easy mounting and retrofitting” Reduced installation work

| Series | Rated flow range (L/min) |

|---|---|

| PFUW | 0 to 60 0 to 100 |

Non F-Gas (CO2 Refrigerant) Refrigerated Thermo-chiller HRZC

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: DeviceNet Compatible Products

Temperature Control Equipment » Chiller Compliant Regulations

Equipment for the Semiconductor Industries (Temperature Adjustment Line) » Chiller Compliant Regulations

Temperature Adjustment Line » Chiller Compliant Regulations

-

・Non F-Gas

・Uses CO2 Refrigerant (R744)

・Greatly reduced GWP

・GWP = 1 Compliant with each country’s refrigerant regulations

EU refrigerant regulations: GWP150 or more

US refrigerant regulations: GWP700 or more

California, US refrigerant regulations: GWP750 or more

∗ “GWP” indicates the global warming potential. The values are based on

the IPCC AR4.

・Air transport possible

・Eliminates the need to pay for F-Gas recovery & disposal

・Eliminates the need for periodic inspections based on the Fluorocarbon

Emissions Control Act (Japan)

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRZC | −20 to 90℃ | 2kW, 4kW, 8kW, 10 kW | ±0.1℃ | Water-cooled refrigeration | Fluorinated fluids 60% ethylene glycol aqueous solution Deionized water/Tap water |

[Low GWP Refrigerant Chiller] Thermo-chiller Standard Type HRSF150/200

Temperature Control Equipment » Chiller Compliant RegulationsEquipment for the Semiconductor Industries (Temperature Adjustment Line) » Chiller Compliant Regulations

Temperature Adjustment Line » Chiller Compliant Regulations

-

・Low GWP Refrigerant Chiller

GWP: 146∗ ∗ Regulation (EU) 2024/573, AIM Act 40 CFR Part 84

EU refrigerant regulations: GWP150 or more

US refrigerant regulations: GWP700 or more

California, US refrigerant regulations: GWP750 or more

・Environmentally friendly R454C as refrigerant (Not available for air

transport)

・No heater is required, as the circulating fluid is heated using only the heat

exhausted by the refrigerating circuit.

・Compatible with power supplies in Europe, Asia, Oceania, and North,

Central, and South America

・3-phase 400 VAC Low-noise design 70 dB(A)

・Outdoor installation IPX4

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Can be used in a wide range of applications!

Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRSF150 HRSF200 | 5 to 35℃ | 15.7kW 20.5kW (Air-cooled) 20.6kW (Water-cooled) | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water 15 to 40% Ethylene glycol aqueous solution Deionized water |

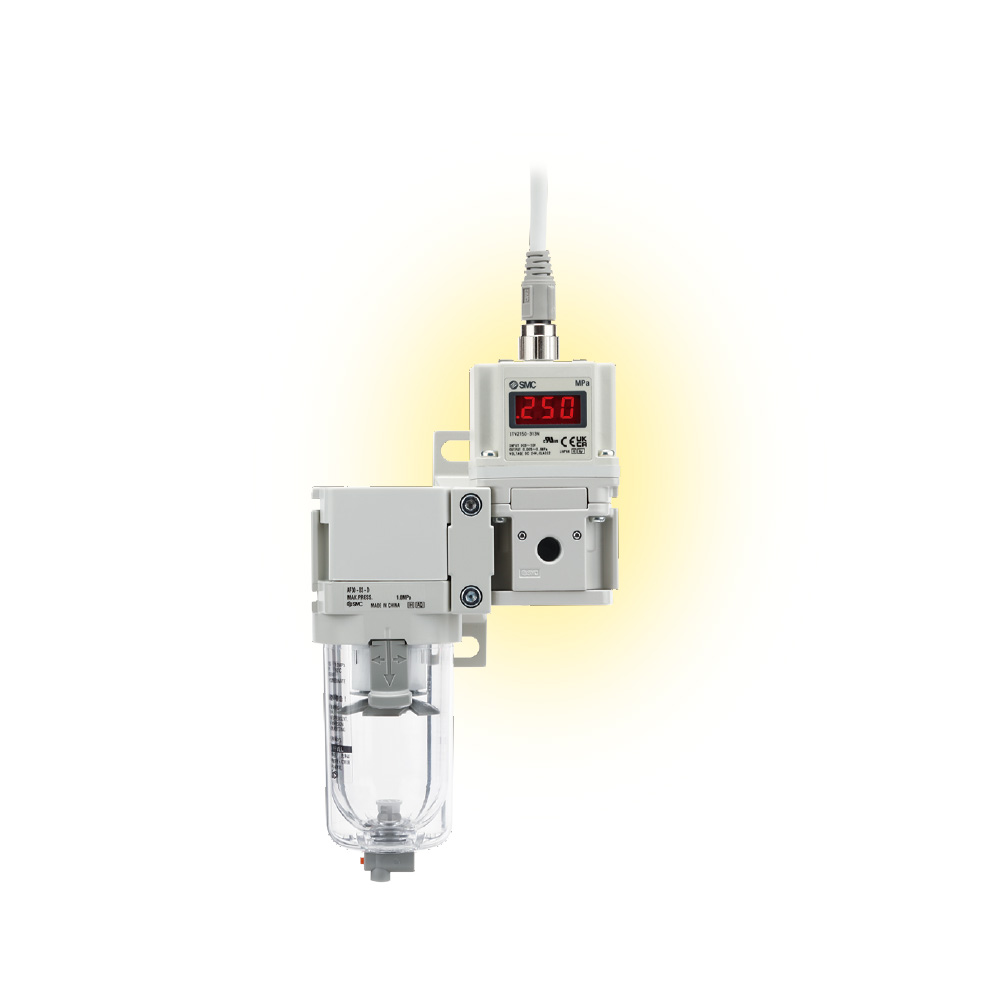

Electro-Pneumatic Regulator / High Flow Rate ITV1100/2100/3100

Modular F.R.L. Units » Modular Connection Compatible Devices-

・For the stepless control of air pressure in proportion to electrical signals

・Flow rate: Max. approx. 5 times (Compared with the existing model)

・Sensitivity: ±0.2% F.S. or less

・Linearity: ±1% F.S. or less

・Hysteresis: 0.5% F.S. or less

Safety Instructions F.R.L. Units/Precautions Series Variations/Pressure Control Equipment Green Procurement (RoHS) Electro-Pneumatic Regulator Application Examples

| Series | Applicable combinations |

|---|---|

| ITV1100 | AF20-D |

| ITV2100 | AF30-D |

| ITV3100 | AF40-D |

Energy Saving, Exhaust-Recovery Booster Regulator VBAE

Booster Regulators » Booster Regulators-

・CO2 emissions (Air consumption): Max. 40% reduction (Based on SMC's

measuring conditions)

Driven by reusing the exhaust air

・Increase factory air pressure by 1.7 times

Air-only operation that requires no power supply, and allows for easy

installation.

・Operation noise: 65 dB (A)

15 dB (A) reduction compared with the existing model (VBA series) (Based

on SMC's measuring conditions)

・Charging time: Max. 50% shorter

・Operating cycles: 50 million cycles or more

Reduced maintenance frequency due to improved life (Based on SMC's

test conditions)

・Compatible with vertical and horizontal installation

・Mounting interchangeability with the existing model (VBA series)

| Series | Port size | Set pressure (MPa) |

|---|---|---|

| VBAE | 1/4,1/2 | 0.3 to 1.2 |

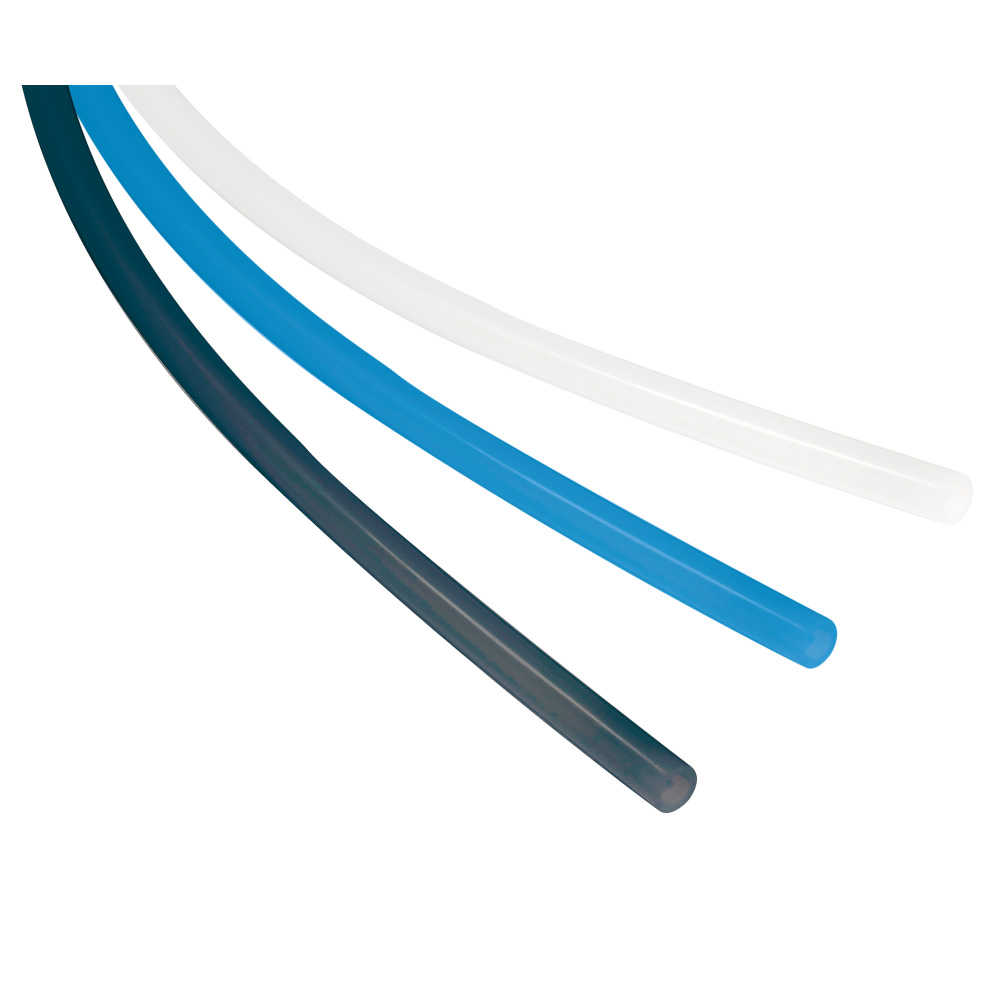

Biomass Tubing TU/TS/T-X309

Fittings and Tubing » Tubing-

・Tubing according to carbon neutrality

・CO2 reduction amount: Max. 18.7 kg

∗ Comparison with the TS series (Tubing O.D. 12 mm;

Tubing I.D. 9 mm), Soft nylon tubing, 100 meters roll

・Reduction in CO2 and greenhouse gases by reducing

the use of petroleum driven raw materials, resulting

in a greater contribution towards decarbonization.

What is a biomass tube?

Tubing produced from plant derived raw biomaterials such

as castor seeds, etc.

| Series | Material | Tubing O.D. Metric size | Color | Fluid |

|---|---|---|---|---|

| TU-X309 | Polyurethane | φ4,φ6,φ8,φ10,φ12 | Black, White, Blue | Air, Water |

| TS-X309 | Soft nylon | φ4,φ6,φ8,φ10,φ12 | White | Air |

| T-X309 | Nylon | φ4,φ6,φ8,φ10,φ12 | Black, White | Air |