There were 1,247 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

NAMUR Interface 3-Port Solenoid Valve VFN200N

Pneumatic Instrumentation Equipment » Solenoid Valves

-

・The interface surface is compliant with NAMUR Standards.

Can be directly installed on industrial valve actuators that comply with NAMUR

| Series | Flow rate characteristics 4/2→5/3(A/B→EA/EB) C | Flow rate characteristics 4/2→5/3(A/B→EA/EB) b | Flow rate characteristics 4/2→5/3(A/B→EA/EB) Cv | Power consumption (W) |

|---|---|---|---|---|

| VFN200N | 5.41 | 0.31 | 1.38 | 1.8 |

Pressure Switch IS

Pneumatic Instrumentation Equipment » Detection Conversion Units

-

・The pressure switch IS100 series can be utilized for automatic air pressure control in a wide variety of fields, such as industrial machinery or chemical plants.

・Pressure adjustment range: 0.02 to 0.1 MPa

・Electric wiring: Various wiring and entry methods can be selected.

・Mechanical service life: 100,000 cycles

| Series | Port size | Pressure adjustment range (MPa) | Contact |

|---|---|---|---|

| IS100 | Rc1/4 | 0.02 to 0.1 | Using micro switch A, B 2 contacts |

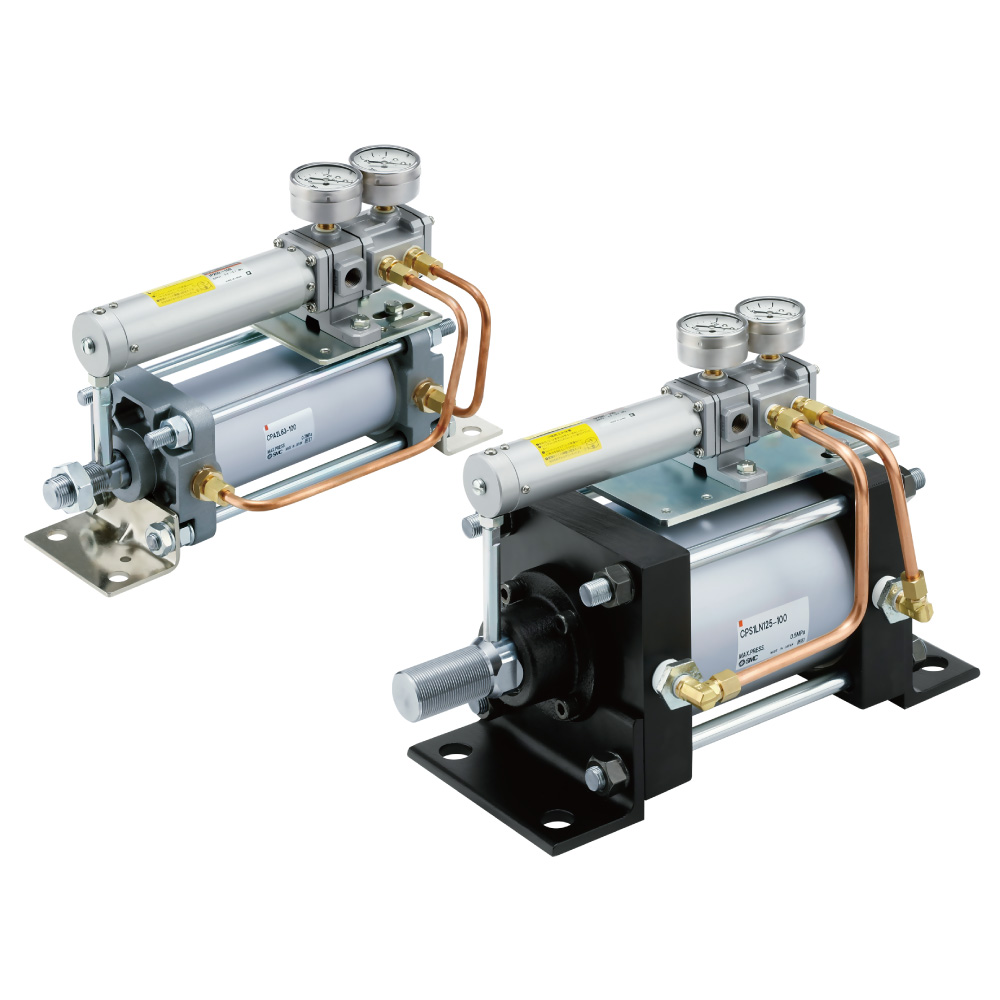

P Cylinder (Cylinder with Positioner) CPA2/CPS1

Pneumatic Instrumentation Equipment » Actuators

-

・Cylinder positioning in proportion to the input signal (air pressure) is possible.

・Correction operation function: Returns to the initial setting position even when the position deviates due to load variations

| Series | Bore size | Stroke (mm) | Air connection port | Supply pressure (MPa) | Input pressure (MPa) |

|---|---|---|---|---|---|

| CPA2 | φ50 to 100 | 25 to 300 | Rc1/4 female thread | 0.3 to 0.7 | 0.02 to 0.1 |

| CPS1 | φ125 to 300 | 30 to 300 | Rc1/4 female thread | 0.3 to 0.7 | 0.02 to 0.1 |

Electro-Pneumatic Transducer IT600/601

Pneumatic Instrumentation Equipment » Electro-Pneumatic Transducers

-

・Air pressure in proportion to the current signal can be output.

・Wide output pressure range: 0.02 to 0.6 MPa

・Fast response

・Independent electric unit/Explosion-proof (flameproof) construction

・Easy span adjustment

| Series | Port size | Supply air pressure (MPa) | Input current |

|---|---|---|---|

| IT600 | Rc1/4 | 0.14 to 0.24 | 4 to 20 mA DC |

| IT601 | Rc1/4 | 0.24 to 0.7 | 4 to 20 mA DC |

Booster Relay IL100/XT240

Pneumatic Instrumentation Equipment » Relays/Valves-

・Used when the piping distance between the instrumentation and operational area is long, or when the operational area has a large capacity

・Can help accelerate actuation speed considerably

| Series | Port size | Pressure ratio | Input/Output pressure |

|---|---|---|---|

| IL100 | Rc1/4, 3/8 | 1:1 | 0.7 MPa |

| XT240 | Rc. NPT 1/4 (SIG), 1 (SUP. OUT) | 1:1 | 0.7 MPa |

Filter Regulator 1301/IW

Pneumatic Instrumentation Equipment » Regulators| Series | Port size | Set pressure (MPa) | Filtration accuracy (μm) |

|---|---|---|---|

| IW | Rc1/4 | 0.02 to 0.2 0.02 to 0.3 0.02 to 0.5 | 5 |

| 1301 | Rc1/4 | 0.02 to 0.2 0.02 to 0.29 0.02 to 0.49 | 5 |

Electro-Pneumatic Positioner/Smart Positioner IP8□00/IP8□01

Pneumatic Instrumentation Equipment » Positioners

-

・Enclosure: JISF8007 IP65 (Compliant with IEC 60529)

・Monitoring function

・Explosion-proof construction

・Electro-pneumatic positioner:

TIIS explosion-proof construction (Exd II BT5)

ATEX intrinsically safe explosion-proof construction

(II 2G Ex h ib II CT5/T6 Gb)

・Smart positioner:

ATEX intrinsically safe explosion-proof construction

(II 1G Ex h ia II CT4/T5/T6 Ga)

・HART transmission function (Smart positioner)

| Description | Series | Type | Port size (Rc, NPT, G) | Supply air pressure (MPa) | Input current |

|---|---|---|---|---|---|

| Electro-pneumatic positioner | IP8000 | Lever type | 1/4 | 0.14 to 0.7 | 4 to 20 mA DC |

| Electro-pneumatic positioner | IP8100 | Rotary type | 1/4 | 0.14 to 0.7 | 4 to 20 mA DC |

| Smart positioner | IP8001 | Lever type | 1/4 | 0.14 to 0.7 | 4 to 20 mA DC |

| Smart positioner | IP8101 | Rotary type | 1/4 | 0.3 to 0.7 | 4 to 20 mA DC |

Sintered Metal Element EB/ES

Industrial Filters/Sintered Metal Elements » Sintered Metal Elements

-

・Large mechanical strength and withstand pressure, Anti-corrosive

・Mechanical process, caulking, brazing, soldering, welding, and simultaneous sintering are possible.

・Can be cleaned and reused

| Series | Material | Nominal filtration accuracy |

|---|---|---|

| EB | Bronze | (1)*, 2, 5, 10, 20, 40, 70, 100, 120 μm *( ): Semi-standard |

| ES | Stainless steel | (1)*, 2, 5, 10, 20, 40, 70, 100, 120 μm *( ): Semi-standard |

Industrial Filter/Vessel Series FGD

Industrial Filters/Sintered Metal Elements » Industrial Filters

-

・Ideal for low-flow filtration (Max. 60 L/min)

・It is possible to select the antistatic specification (FGDE, FGDF).

| Series | Port size | Max. operating pressure | Operating temperature (℃) |

|---|---|---|---|

| FGD | Rc3/8,1/2,3/4 | 0.7, 1 MPa | MAX. 80 |

Rodless Cylinder for Vacuum CYV

High Vacuum Equipment » Rodless Cylinders for VacuumEquipment for the Semiconductor Industries » Slit Valve/Transfer

-

・Air cylinder for transfer in vacuum environments (1.3 x 10-4 Pa)

Safety Instructions System Configuration/Role of Each Line and Component Series Variations Glossary Green Procurement (RoHS)

| Series | Operating environment pressure [Pa (ABS)] | Bore size (mm) |

|---|---|---|

| CYV | Atmosphere to 1.3 x 10-4 | 15, 32 |