There were 368 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Non-contact Gripper XT661

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Special Pads-

・Assists in non-contact workpiece transfer

・Max. workpiece suction distance: 10 mm

・2 types are available:

Cyclone type: High lift: Max. 44 N

Bernoulli type: Amplitude of the workpiece during gripping: ±0.01 mm or less

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

Oval Vacuum Pad (Vacuum Suction Cup) ZP/ZP2

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Pads (Vacuum Suction Cups)

-

・For rectangular, vertically long, and horizontally long workpieces

・Pad form: Oval flat type

・Mounting: Male thread, Female thread

・Vacuum inlet direction: Vertical, Lateral

・Vacuum inlet: Male thread, Female thread, One-touch fitting, Barb fitting

・Buffer: Without, With

Buffer stroke (mm): [ZP] 6, 10, 15, 20, 25

Buffer stroke (mm): [ZP2] 10, 20, 30, 40, 50

Safety Instructions Vacuum Equipment/Precautions Vacuum Pads/Precautions Series Variations Model Selection ZP: Mounting Bracket Assembly (p.189-194) ZP2: Mounting Bracket Assembly (p.195-197) Green Procurement (RoHS)

| Series | Pad form | Pad diameter(mm) |

|---|---|---|

| ZP | Oval flat type | 2×4, 3.5×7, 4×10 |

| ZP2 | Oval flat type | 3.5×7, 4×10, 4×20, 4×30, 5×10, 5×20, 5×30, 6×10, 6×20, 6×30, 8×20, 8×30 |

In-line Type Vacuum Ejector ZU□A

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors-

・Compact and Lightweight

O.D.: ø10.4, Weight: 3.9 g, Overall length: 52 mm

・Port size

ø4, ø6 One-touch fitting, Rc1/8 female thread, ø5/32"

・Vacuum pressure reached [kPa]

Type S: -90, -87, -85

Type L: -48, -40

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] Type S | Max. suction flow [L/min(ANR)] Type L | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) |

|---|---|---|---|---|---|

| ZU03□A | 0.3 | 1.8 | 3.4 | 4.2 | 2 to 8 |

| ZU04□A | 0.4 | 3.2 | 5.8 | 7.7 | 2 to 10 |

| ZU05□A | 0.5 | 7 | 13 | 14 | 2 to 13 |

| ZU07□A | 0.7 | 11 | 16 | 28 | 2 to 20 |

Electric Actuator/High Rigidity Slider Type LEJ

Electric Actuators/Cylinders » Motorless Type-

・Various servo motors can be mounted due to the addition of the motorless type.

・Compatible motors:

Mitsubishi Electric Corporation, YASKAWA Electric Corporation,

SANYO DENKI CO., LTD., OMRON Corporation, Panasonic Corporation,

FANUC CORPORATION, NIDEC INSTRUMENTS,

KEYENCE CORPORATION, FUJI ELECTRIC CO., LTD., MinebeaMitsumi Inc.,

Shinano Kenshi Co., Ltd., ORIENTAL MOTOR Co., Ltd., FASTECH Co., Ltd.,

Rockwell Automation, Inc. (Allen-Bradley), Beckhoff Automation GmbH,

Siemens AG, Delta Electronics, Inc., ANCA Motion

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

| Specification | Model | Stroke (mm) | Work load (kg) | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Motorless Ball screw drive | LEJS40 | 200 to 1200 | Max. 55 | Max. 1800 | 8, 16, 24 |

| Motorless Ball screw drive | LEJS63 | 300 to 1500 | Max. 85 | Max. 1800 | 10, 20, 30 |

Programless Controller LECP1

Electric Actuators/Cylinders » Controllers/Drivers

-

・No programming required

Capable of setting up an electric actuator operation without using a PC or

teaching box

・Speed/acceleration 16-level adjustment

・Compatible with actuators with locks

・3-level pushing force settings

The LECP1 and LECP2 series programless controllers are to be discontinued

as of the end of May 2025.

Consider selecting the JXC51/61 series single-axis controller instead, as it

has interchangeable functions.

* The most recent versions of the JXC51/61 series (Ver. 3.60 and up) and the

ACT Controller 2 setting software (Ver. 1.5.0.0) are required in order to use

the LECP1/LECP2 mode.

▶Click here for details.

Safety Instructions Electric Actuators/Precautions Features

Series Variations Simplified Selection Flow Chart Wiring Method

Green Procurement (RoHS)

Series Variations Simplified Selection Flow Chart Wiring Method

Green Procurement (RoHS)

| Type | Series | Compatible motor | Power supply voltage | Parallel I/O Input | Parallel I/O Output | Number of step data |

|---|---|---|---|---|---|---|

| Programless type | LECP1 | Step motor (Servo/24 VDC) | 24 VDC ±10% | 6 (Photo-coupler isolation) | 6 (Photo-coupler isolation) | 14 points |

Slim-line Power Clamp Cylinder CKZ2N-X2346

Air Cylinders » Clamp CylindersArc Welding Process Equipment » Specialty Cylinders

-

・The distance accuracy from the reference hole to the lower surface of the clamp arm is ±0.1 mm.

・Easy setup with a scale

The guide of the appropriate position can be checked visually when adjusting the shim.

・Reduced width

Easy torch entry for spot welding, arc welding, etc.

Safety Instructions Actuators/Precautions Auto Switches/Precautions

Introduction of Arc Welding Process Equipment Green Procurement (RoHS)

Introduction of Arc Welding Process Equipment Green Procurement (RoHS)

| Series | Arm opening angle | Bore size (mm) |

|---|---|---|

| CKZ2N-X2346 | 30º, 45º, 60º, 75º, 90º 105º, 120º, 135º | 50, 63, 80 |

Mechanically Jointed Rodless Cylinder MY2

Air Cylinders » Mechanically Jointed Rodless Cylinders

-

・Height has been reduced by a maximum of 30% compared to the mechanically jointed rodless cylinder, MY1H series. Furthermore, it is possible to replace the cylinder for the drive unit while the workpiece is mounted.

Safety Instructions Actuators/Precautions Auto Switches/Precautions

Model Selection/Technical Data Quick Selection Tables Made to Order Common Specifications

Green Procurement (RoHS)

Model Selection/Technical Data Quick Selection Tables Made to Order Common Specifications

Green Procurement (RoHS)

| Type | Series | Action | Bore size (mm) |

|---|---|---|---|

| Cam follower guide | MY2C | Double acting | 16,25,40 |

| Linear guide | MY2H | Double acting | 16,25,40 |

| Linear guide | MY2HT | Double acting | 16,25,40 |

5-Port Air Operated Valve VZA2000/4000

Directional Control Valves » Air Operated Valves

-

・Can be used with the same manifolds as the VZ2000/4000 series.

・Can be mounted on VQZ2000/3000 manifolds.

| Series | Flow rate characteristics 4/2→5/3(A/B→EA/EB) C[dm3/(s・bar)] | Flow rate characteristics 4/2→5/3(A/B→EA/EB) b | Flow rate characteristics 4/2→5/3(A/B→EA/EB) Cv | Applicable cylinder size |

|---|---|---|---|---|

| VZA2000 | 0.90 | 0.25 | 0.21 | φ40 |

| VZA4000 | 2.2 | 0.19 | 0.54 | φ50 |

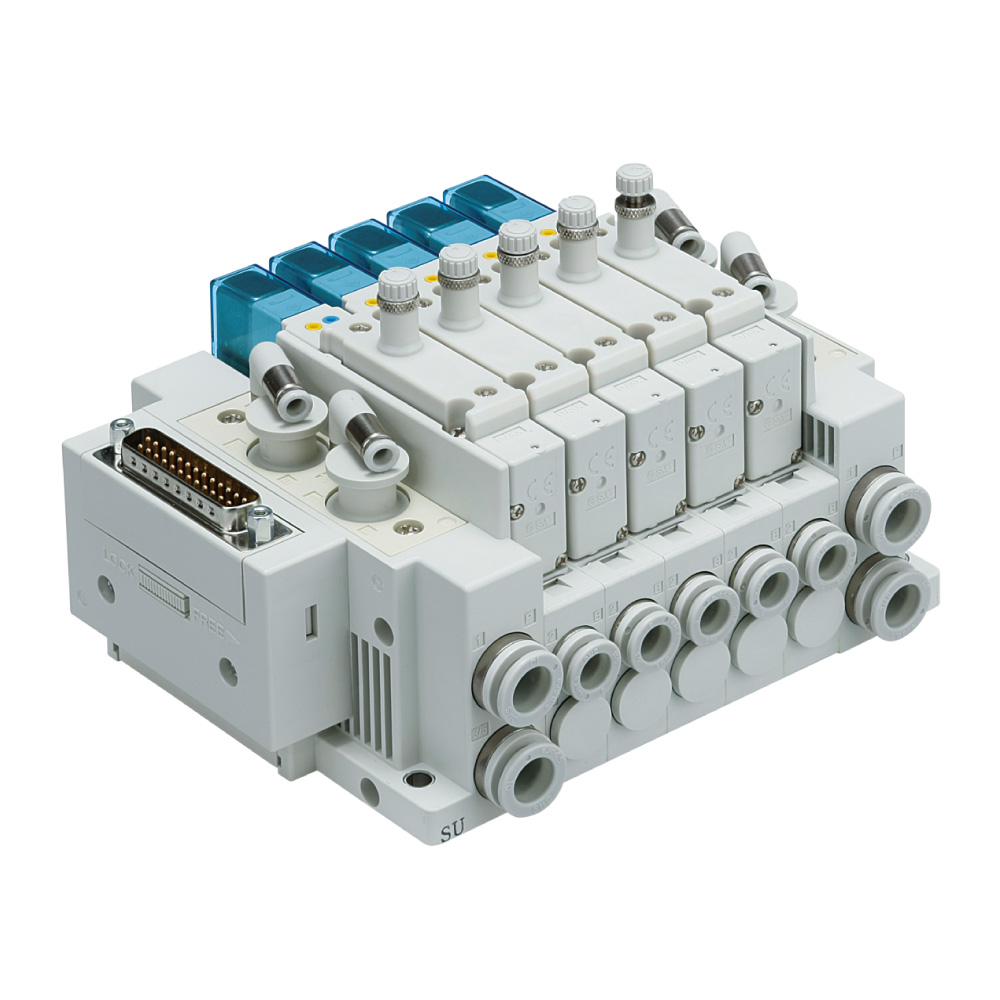

Vacuum Release Valve with Restrictor SY3A□R SY5A□R

Directional Control Valves » Pilot Operated 4/5 Port Solenoid ValvesVacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Release Valve Units

-

・Vacuum suction and release can be controlled with a single valve.

・With a restrictor that can adjust the flow rate of the release air

・Can be mounted on the same manifold as the standard valve

* When the individual EXH spacer is used

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series |

|---|

| SY3A□R |

| SY5A□R |

Solid State Auto Switch UL/CSA Certified D-M9□-551/918

Air Cylinders » Auto Switches-

・D-M9□-551:UL, CSA certified

D-M9□-918:UL, CSA certified + Secondary battery compatible

・Dimensions and Specifications: The same as those of the standard

(general purpose) D-M9□ auto switch

| Series | Mounting | Specifications |

|---|---|---|

| D-M9□-551 | Solid State Auto Switch | UL, CSA certified |

| D-M9□-918 | Solid State Auto Switch | UL, CSA certified + Secondary battery compatible |