There were 1,276 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Heavy Duty Auto Drain ADH

Air Preparation Equipment » Auto Drains/Differential Pressure Gauges

-

・Easy maintenance

Easy to maintain without removing pipes

・Electric power is not required, and the wasting of air can be prevented.

Float type drain allows for automatic draining without electric power

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Series | Port size | Auto drain |

|---|---|---|

| ADH4000 | 1/2 | Float type |

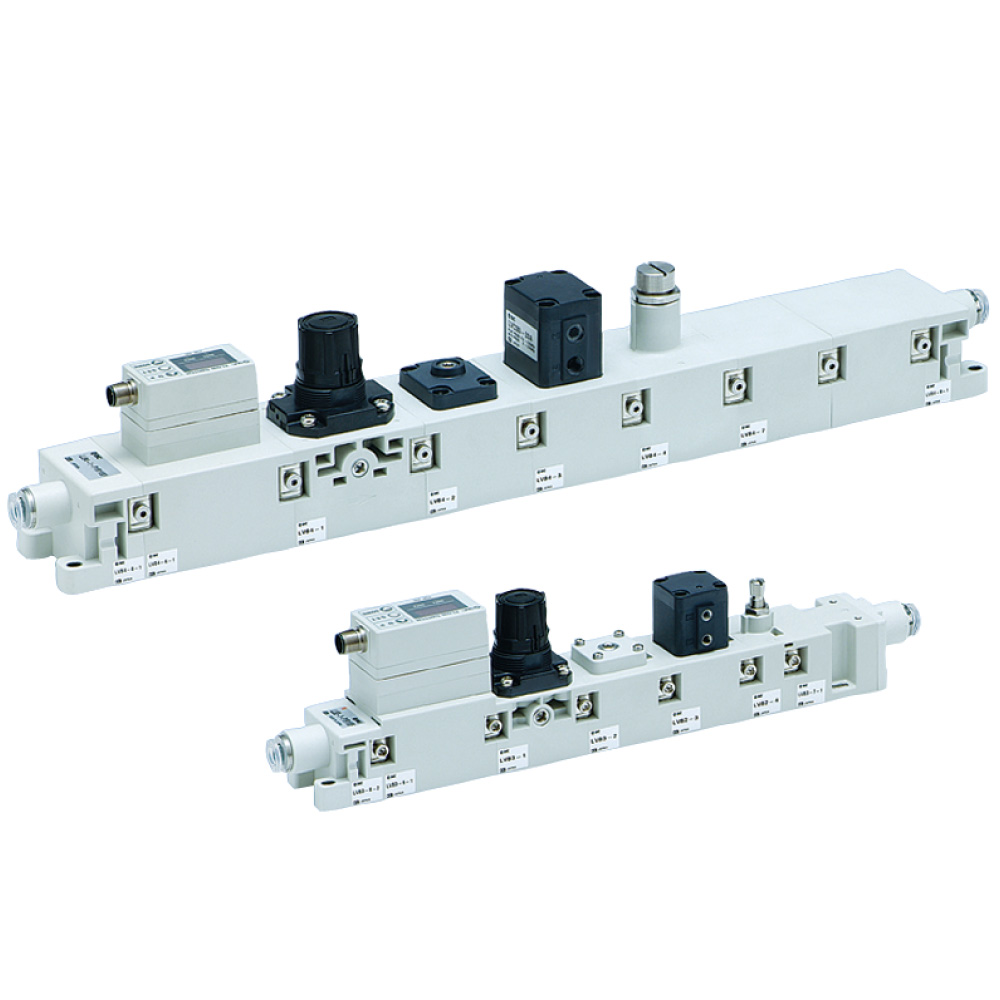

Clean Air Module LLB

Air Preparation Equipment » Air Preparation FiltersClean Series/Low-Particle Generation » Compressed Air Cleaning Filter Series

Clean Series/Low-Particle Generation » Clean Gas Filters/Air Filters

-

・Modularized clean equipment (Reduced piping labor/Space saving)

Makes clean air easily available

・Nominal filtration rating: 0.01 μm (Filtration efficiency: 99.99%)

・Wetted parts: Grease-free, Silicone-free

・Assembled in a clean room, Shipped and packed in double packaging

・24 combinations are available.

Note) Inlet air conditions ISO 8573-1 Quality grade: Equivalent to 1.4.1 to 1.6.1

Safety Instructions Air Preparation Equipment/Precautions Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Series | Fluid | Set pressure | Flow range L/min (ANR) |

|---|---|---|---|

| LLB3 | Clean air N2 gas Note) | 0.05 to 0.4 MPa | 5 to 100 |

| LLB4 | Clean air N2 gas Note) | 0.05 to 0.4 MPa | 50 to 500 |

Water Separator AMG

Air Preparation Equipment » Air Preparation Filters

-

・Compressed air without water can be obtained.

・Water drop removal ratio: 99%

・Easily connects to the air line to remove moisture!

Safety Instructions Air Preparation Equipment/Precautions Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) Element Part No.

| Series | Air flow capacity L/min (ANR) | Port size |

|---|---|---|

| AMG | 300 to 12000 | 1/8 to 2 |

Refrigerated Air Dryer IDU □E

Air Preparation Equipment » Air Dryers

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) Proposal for the Use of a Separate Refrigerated Air Dryer

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) Proposal for the Use of a Separate Refrigerated Air Dryer

| Series | Rated inlet condition | Air flow capacity (m3/min[ANR]) 50 Hz | Air flow capacity (m3/min[ANR]) 60 Hz | Applicable air compressor (kW) | Refrigerant | Port size | Compressor output |

|---|---|---|---|---|---|---|---|

| IDU3E | 55℃ 0.7 MPa | 0.32 | 0.37 | 2.2 | R134a (HFC) | Rc3/8 | Less than 7.5kw |

| IDU4E | 55℃ 0.7 MPa | 0.52 | 0.57 | 3.7 | R134a (HFC) | Rc1/2 | Less than 7.5kw |

| IDU6E | 55℃ 0.7 MPa | 0.75 | 0.82 | 5.5 | R134a (HFC) | Rc3/4 | Less than 7.5kw |

| IDU8E | 55℃ 0.7 MPa | 1.1 | 1.2 | 7.5 | R134a (HFC) | Rc3/4 | Less than 7.5kw |

| IDU11E | 55℃ 0.7 MPa | 1.5 | 1.7 | 11 | R134a (HFC) | Rc3/4 | Less than 7.5kw |

| IDU15E1 | 55℃ 0.7 MPa | 2.6 | 2.8 | 15 | R134a (HFC) | Rc1 | Less than 7.5kw |

| IDU22E | 55℃ 0.7 MPa | 3.9 | 4.3 | 22 | R407C (HFC) | R1 | Less than 7.5kw |

| IDU37E | 55℃ 0.7 MPa | 5.7 | 6.1 | 37 | R407C (HFC) | R1 1/2 | Less than 7.5kw |

| IDU55E | 55℃ 0.7 MPa | 8.4 | 9.8 | 55 | R407C (HFC) | R2 | Less than 7.5kw |

| IDU75E | 55℃ 0.7 MPa | 11.0 | 12.5 | 75 | R407C (HFC) | R2 | Less than 7.5kw |

Air Tank AT

Air Preparation Equipment » Aftercoolers/Air Tanks

-

・This air tank accumulates the compressed air from compressors,

prevents it from being pulsated, and cools it.

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Series | Port size | Tank capacity (L) |

|---|---|---|

| AT | 1/2 to 4B flange | 100 to 3000 |

Vacuum Flow ZH-X226/-X249/-X338

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum FlowAir Blowing Equipment » Air Blowing Equipment

-

・By supplying compressed air, large blow and vacuum flow rates are available.

Blow: Max. 1550 L/min (ANR)

Vacuum: Max. 880 L/min (ANR)

・Application examples

Adsorption transfer, coolant blow to blow off cutting chips, adsorption transfer

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Suction flow [L/min(ANR)] | Discharge flow [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|

| ZH-X226 | 405 | 700 | 297 |

| ZH-X338 | 880 | 1,550 | 570 |

| ZH-X249 | 820 | 1,160 | 340 |

Vacuum Gripper for Collaborative Robots ZXP7□-X1□-ASSISTA

for Mitsubishi Electric Corporation MELFA ASSISTA

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Gripper for Collaborative RobotsAir Gripper for Collaborative Robots » Vacuum Grippers

-

・Operate by simply connecting 1 compressed air supply tube and an electrical wiring M12 connector.

・Integrated vacuum ejector, air supply valve, pressure switch, and cups

・Features a rounded appearance without corners

・A wide variety of cup variations are available to support a wide range of workpieces.

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Cup form | Cup diameter | Suction flow rate [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|---|

| ZXP7□-X1□-ASSISTA | Flat Flat with rib Bellows Thin flat Multistage bellows 2.5-stage bellows 5.5-stage bellows | φ8 to φ32 | 17 | 57 |

Non-contact Gripper XT661

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Special Pads-

・Assists in non-contact workpiece transfer

・Max. workpiece suction distance: 10 mm

・2 types are available:

Cyclone type: High lift: Max. 44 N

Bernoulli type: Amplitude of the workpiece during gripping: ±0.01 mm or less

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

Oval Vacuum Pad (Vacuum Suction Cup) ZP/ZP2

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Pads (Vacuum Suction Cups)

-

・For rectangular, vertically long, and horizontally long workpieces

・Pad form: Oval flat type

・Mounting: Male thread, Female thread

・Vacuum inlet direction: Vertical, Lateral

・Vacuum inlet: Male thread, Female thread, One-touch fitting, Barb fitting

・Buffer: Without, With

Buffer stroke (mm): [ZP] 6, 10, 15, 20, 25

Buffer stroke (mm): [ZP2] 10, 20, 30, 40, 50

Safety Instructions Vacuum Equipment/Precautions Vacuum Pads/Precautions Series Variations Model Selection ZP: Mounting Bracket Assembly (p.189-194) ZP2: Mounting Bracket Assembly (p.195-197) Green Procurement (RoHS)

| Series | Pad form | Pad diameter(mm) |

|---|---|---|

| ZP | Oval flat type | 2×4, 3.5×7, 4×10 |

| ZP2 | Oval flat type | 3.5×7, 4×10, 4×20, 4×30, 5×10, 5×20, 5×30, 6×10, 6×20, 6×30, 8×20, 8×30 |

Vacuum Filter AFJ

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Related Equipment for Vacuum SystemsVacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Air Suction Filters

-

・Prevents problems with vacuum equipment!

・Nominal filtration rating: 5, 40, 80 μm

・Large flow capacity: Max. 660 L/min (ANR)

・Elements can be reused by washing them.

・Water droplets can be removed.

・The bowl is covered with a transparent bowl guard.

| Series | Port size | Recommended flow rate L/min (ANR) | Filtration |

|---|---|---|---|

| AFJ | 1/8,1/4,3/8,1/2 | 180,380,660 | 5,40,80 |