There were 1,029 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Line Filter AFF

Mist Separator AM

Micro Mist Separator AMD

Micro Mist Separator with Pre-filter AMH

Activated Carbon Filter AMK

Air Preparation Equipment » Air Preparation Filters-

・Modular connection type

・Compressed air purity class: ISO 8573

・Face-to-face and depth dimensions reduced by 30%

・Weight reduced by 50%

AFF/AM□20: 0.19 kg (Existing model: 0.38 kg)

・Flow capacity increased by 50%

・No tools are required.

Easy replacement of the element

・Transparent bowl guard (2-layer construction)

・Color-identifiable elements

・With element service indicator

・With clogging switch/With element service indicator

Safety Instructions Air Preparation Equipment/Precautions Selection/Technical Data Green Procurement (RoHS) Element Part No.

| Type | Series | Filtration (μm) | Oil mist concentration on the outlet side | Air flow (L/min[ANR]) | Port size |

|---|---|---|---|---|---|

| Line filter | AFF | 1.0 (Filtration efficiency: 99%) | - | 300 to 3700 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

| Mist separator | AM | 0.1 (Filtration efficiency: 99%) | 1 (≈ 0.8 ppm) or less | 300 to 3700 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

| Micro mist separator | AMD | 0.01 (Filtration efficiency: 99.9%) | 0.1 (≈ 0.08 ppm) or less | 300 to 3700 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

| Micro Mist Separator with Pre-filter | AMH | 0.01 (Filtration efficiency: 99.9%) | 0.1 (≈ 0.08 ppm) or less | 750 to 1500 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

| Activated carbon filter | AMK | - | 0.003 (≈ 0.0025 ppm) or less | 300 to 3700 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 |

Thermo-dryer with Air Temperature Adjustment Function IDH□

Air Preparation Equipment » Air DryersTemperature Control Equipment » Air Temperature Controllers

-

・Stable supply of temperature and pressure controlled dry clean air

Can supply compressed air with the same conditions and quality

regardless of the season

・Application example:

Supplying compressed air with constant conditions to air bearings

mounted on a tool

・Built-in filter

Nominal filtration: 0.01 μm (99.9% filtration efficiency)

Outlet oil mist concentration: Max. 0.01 mg/m3 (ANR)

Outlet cleanliness: Particles of 0.3 μm or more: 3.5 particles/L (ANR)

or less

・Compatible with power supplies from around the world Single-phase

100, 200, 230 VAC (50/60 Hz)

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Series | Air flow capacity L/min(ANR) | Outlet air temperature adjustment range | Outlet air set pressure range | Outlet air temperature stability | Cooling method | Compressor output |

|---|---|---|---|---|---|---|

| IDH□4 | 100 to 500 | 15 to 30℃ | 0.15 to 0.85 MPa | ±0.1 | Heater operation PID control | Less than 7.5kw |

| IDH□6 | 200 to 800 | 15 to 30℃ | 0.15 to 0.85 MPa | ±0.1 | Heater operation PID control | Less than 7.5kw |

Refrigerated Air Dryer IDF

Air Preparation Equipment » Air Dryers-

・Applicable for the high-temperature environments

Ambient temperature : Max. 45℃

Inlet air temperature : Max. 65℃

・Increased air flow capacity

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) Proposal for the Use of a Separate Refrigerated Air Dryer

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) Proposal for the Use of a Separate Refrigerated Air Dryer

| Series | Rated inlet condition | Air flow capacity (m3/min[ANR]) 50 Hz | Air flow capacity (m3/min[ANR]) 60 Hz | Refrigerant | Port size | Compressor output |

|---|---|---|---|---|---|---|

| IDF60 | 35℃ 0.7 MPa | 5.6 | 6.5 | R410A(HFC) GWP:2088 | R1 | Less than 7.5kw |

| IDF70 | 35℃ 0.7 MPa | 8 | 9.1 | R410A(HFC) GWP:2088 | R1 1/2 | Less than 7.5kw |

| IDF80 | 40℃ 0.7 MPa | 11.6 | 13.6 | R410A(HFC) GWP:2088 | R2 | Less than 7.5kw |

| IDF90 | 40℃ 0.7 MPa | 14.3 | 16.4 | R410A(HFC) GWP:2088 | R2 | Less than 7.5kw |

Air Cooled Aftercooler HAA

Air Preparation Equipment » Aftercoolers/Air Tanks

-

・Can cool high-temperature compressed air from compressors down to

40°C or less and efficiently remove moisture from the air

・Cooling equipment is not required for this air-cooled type.

・Easy maintenance and reasonable running costs,

No need to worry about freezing or running out of water supply.

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Series | Applicable compressor (kW) | Air flow capacity L/min (ANR) |

|---|---|---|

| HAA | 7.5 to 37 | 1000 to 5700 |

Adsorption Plate SP

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Related Equipment for Vacuum Systems

-

・Ideal for the adsorption and fixing in place of thin sheets, glass panels, and soft workpieces

Workpieces will not be deformed since they are adsorbed with multiple micro air vents on the adsorption surface.

・A high level of machining accuracy

・Strong adsorption force

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Shape | Adsorption surface size | Sintered metallic element particle dia. | Suction port |

|---|---|---|---|---|

| SP | Rectangular, Square | □50 x 50 mm, □100 x 100 mm, □150 x 150 mm □200 x 200 mm, □250 x 250 mm, □300 x 300 mm | φ0.3 (Sphere) | 1/8 |

Vacuum Gripper for Collaborative Robots ZXP7□21-X1

for the FANUC CORPORATION CRX Series

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Gripper for Collaborative RobotsAir Gripper for Collaborative Robots » Vacuum Grippers

-

・Plug and Play configuration for immediate use

・FANUC CRX plug-in software

・Operate by simply connecting 1 compressed air supply tube and an electrical wiring M8 connector.

・Integrated vacuum ejector, air supply/release valve, pressure sensor, and cups

・Standards: Conforming to ISO 9409-1-50-4-M6

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Cup form | Cup diameter | Suction flow rate [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|---|

| ZXP7□21-X1 | Flat Flat with rib Bellows Thin flat Multistage bellows 2.5-stage bellows 5.5-stage bellows | φ8 to φ32 | 17 | 57 |

Air Suction Filter ZFA

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Air Suction Filters

-

・Prevents problems related to vacuum circuits or airborne contaminants

・Provides a large filter element surface

| Series | Port size | Flow rate L/min (ANR) | Filtration (μm) |

|---|---|---|---|

| ZFA10 | 1/8 | 50 | 30 |

| ZFA20 | 1/4 | 200 | 30 |

Vacuum Ejector ZH

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors-

・Compact and lightweight

Overall length: Max. 11% reduction (6.7 mm shorter) [Body ported type]

Port height: Max. 25% reduction (9.1 mm shorter) [Body ported type]

Weight: Max. 74% reduction (65.1 g lighter) [Body ported type]

Volume: Max. 39% reduction (14.1 cm3 reduction) [Box type]

・4 mounting types:

Direct mounting, Standard bracket mounting, L-bracket mounting,

DIN rail mounting

・A silencer and standard bracket are available. (Body ported type only)

| Body type | Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) |

|---|---|---|---|---|---|

| Body ported type | ZH05DSA | 0.5 | 6 | 13 | 2 to 13 |

| Body ported type | ZH07DSA | 0.7 | 12 | 27 | 2 to 20 |

| Body ported type | ZH10DSA | 1.0 | 26 | 52 | 2 to 32 |

| Body ported type | ZH13DSA | 1.3 | 40 | 88 | 2 to 50 |

| Body ported type | ZH15DSA | 1.5 | 58 | 117 | 2 to 100 |

| Body ported type | ZH18DSA | 1.8 | 76 | 165 | 2 to 125 |

| Body ported type | ZH20DSA | 2.0 | 90 | 201 | 2 to 150 |

| Box type (Built-in silencer) | ZH05B□A | 0.5 | 6 | 13 | 2 to 13 |

| Box type (Built-in silencer) | ZH07B□A | 0.7 | 12 | 27 | 2 to 20 |

| Box type (Built-in silencer) | ZH10B□A | 1.0 | 26 | 52 | 2 to 32 |

| Box type (Built-in silencer) | ZH13B□A | 1.3 | 40 | 88 | 2 to 50 |

| Box type (Built-in silencer) | ZH15B□A | 1.5 | 58 | 117 | 2 to 100 |

| Box type (Built-in silencer) | ZH18B□A | 1.8 | 76 | 165 | 2 to 125 |

| Box type (Built-in silencer) | ZH20B□A | 2.0 | 90 | 201 | 2 to 150 |

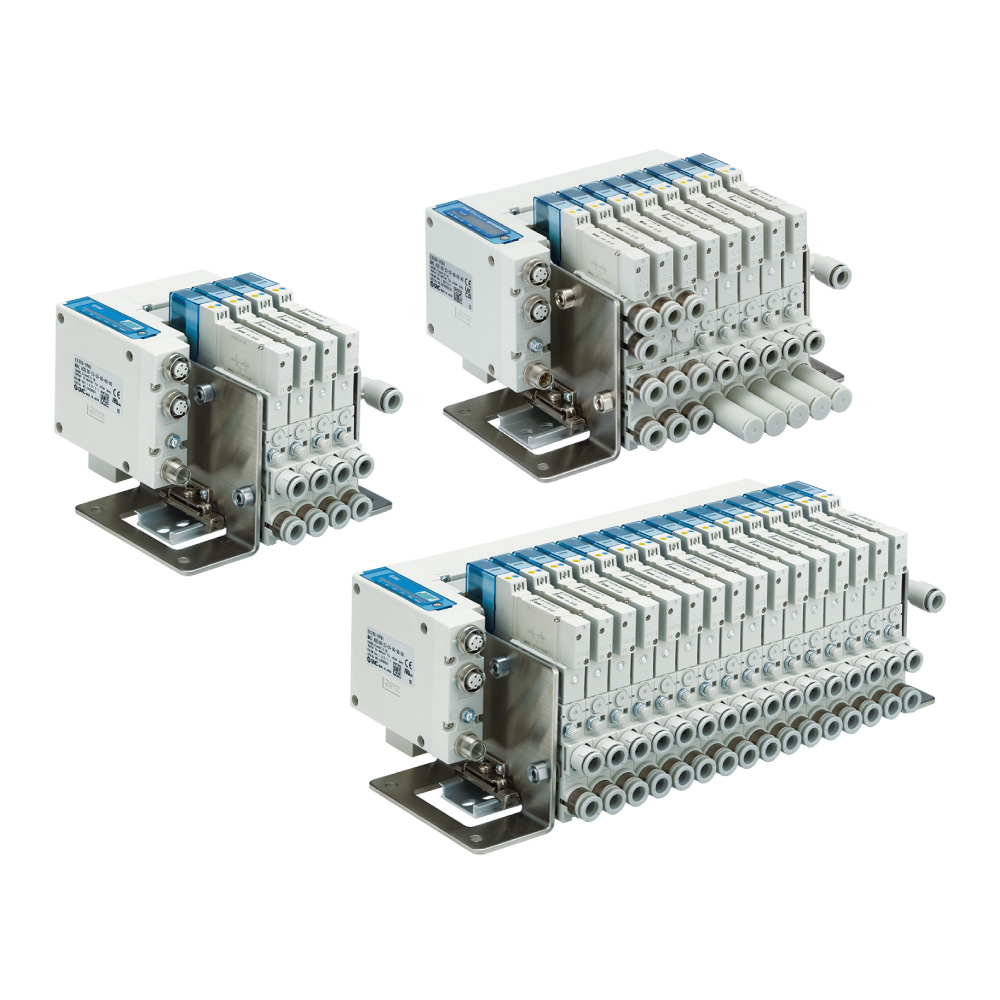

Vacuum Manifold for Fieldbus System ZKJ

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump SystemsIndustrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: PROFINET Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherNet/IP Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: IO-Link Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherCAT Compatible Products

IO-Link Devices » Vacuum Unit/Vacuum Manifold

-

・Vacuum pads and actuator driving can be controlled with a single

manifold [New]

・Positive pressure unit [New]

5-port solenoid valve

・Vacuum unit

Energy saving ejector Air consumption: 92% reduction

・Fieldbus compatible

Space saving: Requires no separate input/output units

Reduced wiring time

Compatible protocols: PROFINET, IO-Link, EtherNet/IP, EtherCAT

・Exhaust sealing function

Quick workpiece release

・4 stations/8 stations/12 stations/16 stations manifold compatible

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|

| ZKJ07 | 0.7 | 31 | 26 |

| ZKJ10 | 1.0 | 53 | 48 |

| ZKJ12 | 1.2 | 63 | 68 |

| ZKJ15 | 1.5 | 74 | 102 |

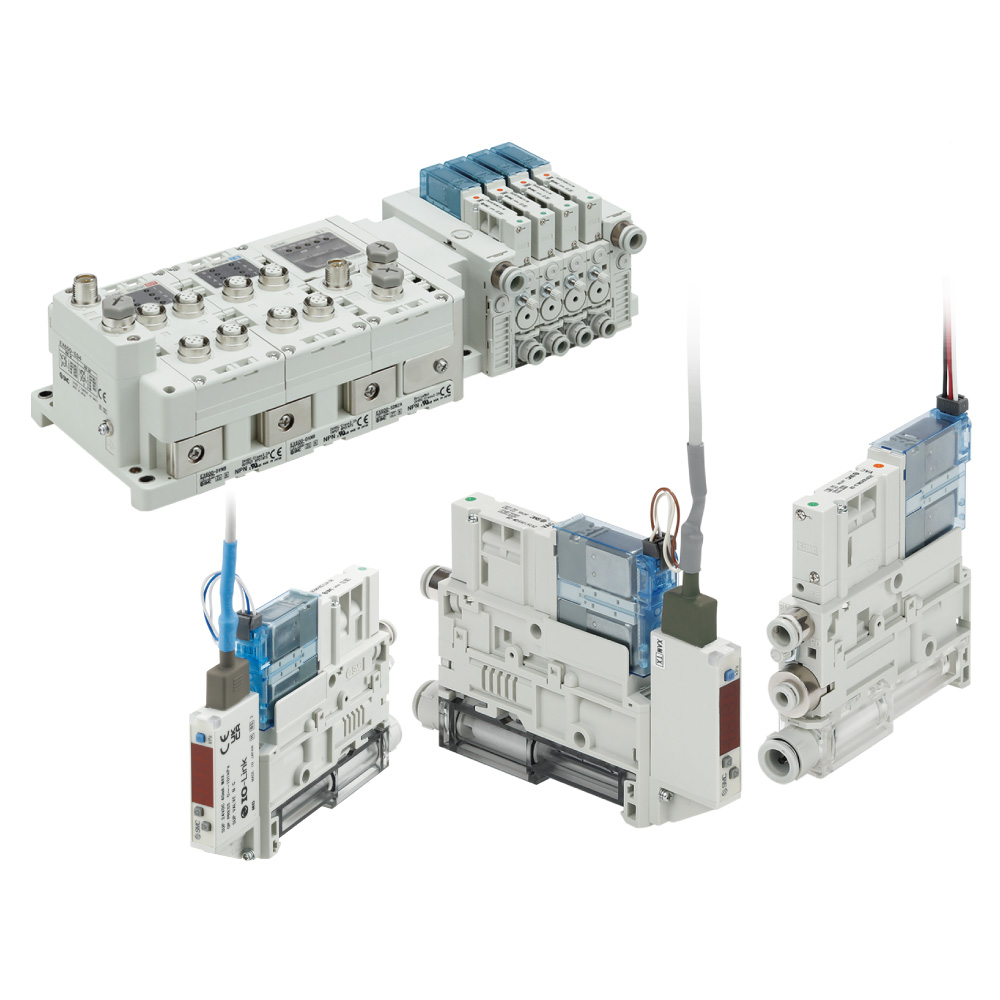

Vacuum Unit (Vacuum Generators) ZK2□A

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems-

・Supply valve: An N.O. specification has been added.

Can hold vacuum∗ even when the power goes out or is turned off

Prevents the sudden dropping of workpieces∗

∗ Supposing the supply pressure is being maintained

・An IO-Link compatible pressure switch has been added.

Allows for ejector control with a single communication line

Reading of the device information and parameter batch settings are

possible.

・Compatible with ejector systems and vacuum pump systems

・Energy saving ejector

Air supply is cut-off when vacuum is reached.

Air consumption: 93% reduction (Under SMC’s measurement conditions)

・More efficient ejector: Suction flow increased by 50% (Compared to other

SMC 1-stage ejectors)

・Energy saving efficiency: 93% reduction

・Improved low noise and suction flow by adoption of a high-noise

reduction silencer

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZK2□07 | 0.7 | 29 | 24 | 2 to 40 | ZK2□00 |

| ZK2□10 | 1.0 | 44 | 40 | 2 to 50 | ZK2□00 |

| ZK2□12 | 1.2 | 61 | 58 | 2 to 125 | ZK2□00 |

| ZK2□15 | 1.5 | 67 | 90 | 2 to 150 | ZK2□00 |