There were 1,239 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

5-Port Air Operated Valve VFRA3000/4000

Directional Control Valves » Air Operated Valves

-

・Can be used with the same manifolds as the VFR3000/4000 series non plug-in type.

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data Green Procurement (RoHS)

| Series | Flow rate characteristics 4/2→5/3(A/B→EA/EB) C[dm3/(s・bar)] | Flow rate characteristics 4/2→5/3(A/B→EA/EB) b | Flow rate characteristics 4/2→5/3(A/B→EA/EB) Cv | Applicable cylinder size |

|---|---|---|---|---|

| VFRA3000 | 8.6 | 0.37 | 2.2 | φ100 |

| VFRA4000 | 14 | 0.30 | 3.7 | φ125 |

Wireless System EXW1/EX600-W

Directional Control Valves » Reduced-wiring Fieldbus System (Serial Transmission System)IO-Link Compatible Products » IO-Link Master

Industrial Device Communication Equipment/Wireless System » Wireless System: PROFINET Compatible Products

Industrial Device Communication Equipment/Wireless System » Wireless System: EtherNet/IP Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: PROFINET Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherNet/IP Compatible Products

Industrial Device Communication Equipment/Wireless System » Wireless System: IO-Link Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: IO-Link Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: EtherCAT Compatible Products

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: CC-Link Compatible Products

Industrial Device Communication Equipment/Wireless System » Wireless System: CC-Link Compatible Products

Directional Control Valves » Wireless System

Industrial Device Communication Equipment/Wireless System » Wireless System: EtherCAT Compatible Products

Industrial Device Communication Equipment/Wireless System » Wireless System: DeviceNet Compatible Products

-

・Analog input, digital input/output, and valve manifold have been

added to the compact type EXW1 series. [New]

・Noise resistance

Uses the 2.4 GHz ISM frequency band

Frequency hopping: Every 2 ms (Fastest)

・Communication cables not required

Reduced wiring work, space, and cost

Minimized disconnection risk

・Provides communication stability in FA environments

・Compact and lightweight (EXW1)

Volume: Approx. 81% reduction, Weight: Approx. 76% reduction

▶IO-Link Master

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Fieldbus System Precautions

Industrial IoT Cybersecurity Remote I/O, goes to “Wireless” Glossary of Fieldbus Terms Green Procurement (RoHS)

Industrial IoT Cybersecurity Remote I/O, goes to “Wireless” Glossary of Fieldbus Terms Green Procurement (RoHS)

| Series | Enclosure | Communication protocol | Applicable valve |

|---|---|---|---|

| EXW1 | IP20/IP67 | DeviceNet® CC-Link EtherNet/IP™ EtherCAT® PROFINET OPC UA | JSY1000, 3000, 5000 |

3-Port Solenoid Valve VQ100

Directional Control Valves » Direct Operated 3/4/5 Port Solenoid Valves

-

・High speed, stable response

・Copper-free

・A wide variety of wiring methods are available.

・Can be used for vacuum applications

・Manifold type no.: VV3Q11, VV3Q12

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Type | Flow rate characteristics 2→3 (2→1) C[dm3/(s・bar)] | Flow rate characteristics 2→3 (2→1) b | Flow rate characteristics 2→3 (2→1) Cv | Power consumption (W) | For use in vacuum applications |

|---|---|---|---|---|---|---|

| VQ100 | Standard Large flow capacity | 0.083 0.14 | 0.28 0.25 | 0.021 0.036 | 1.0 0.5 (Low wattage type) | -100 kPa |

Large Size 3-Port Solenoid Valve VP3145/3165/3185

Directional Control Valves » Pilot Operated 3 Port Solenoid Valves

-

・Large flow capacity, small exhaust resistance

・Easy conversion to N.C. or N.O.

∗ The VP3145/3165/3185 series (AC coil) will be discontinued in September

2024.

Please select the VG342 instead of the VP3145 series.

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Flow rate characteristics 2→3(OUT→EXH) C[dm3/(s・bar)] | Flow rate characteristics 2→3(OUT→EXH) b | Flow rate characteristics 2→3(OUT→EXH) Cv | Power consumption (W) | For use in vacuum applications |

|---|---|---|---|---|---|

| VP3145 | 26 | 0.35 | 7.0 | 12 | -101.2 kPa |

| VP3165 | Effective area: 330 mm2 | Effective area: 330 mm2 | Effective area: 330 mm2 | 12 | -101.2 kPa |

| VP3185 | Effective area: 670 mm2 | Effective area: 670 mm2 | Effective area: 670 mm2 | 12 | -101.2 kPa |

4-Port Solenoid Valve/Cassette Type Manifold SJ1000/2000/3000/4000

Directional Control Valves » Pilot Operated 4/5 Port Solenoid ValvesEquipment for the Semiconductor Industries » Exhaust Line

Features

Features

Click here to see the catalog for

the 60JD/60GD manifold

(flat ribbon cable/PC wiring compatible type).

-

・Low-profile cassette type with baseless structure

・Takes up minimal space with a body width of 6.5 mm (SJ1000),

7.5 mm (SJ2000), 10 mm (SJ3000A), or 15 mm (SJ4000)

・Allows for the mixed mounting of 5 SJ series valve sizes

・The multi-pin connector makes it easy to add or subtract stations or to

exchange valves.

・One side solenoid

・4-position, dual 3-port specifications are available.

・Manifold type no.: SS5J1, SS5J2, SS5J3, SS5J4

*The EX510 series is to be discontinued. When designing new equipment

and facilities, consider using another series (EX260/EX600) instead

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Flow rate characteristics 4/2 → 3/5 (A/B → E) C[dm3/(s・bar)] | Flow rate characteristics 4/2→3/5(A/B→E) b | Flow rate characteristics 4/2→3/5(A/B→E) Cv | Applicable cylinder size Speed: At 100 mm/s | Power consumption (W) |

|---|---|---|---|---|---|

| SJ1000 | 0.32 | 0.33 | 0.08 | ø32 | 0.55 (Standard) 0.23 (With power-saving circuit) |

| SJ2000 | 0.36 | 0.13 | 0.08 | ø40 | 0.55 (Standard) 0.23 (With power-saving circuit) |

| SJ3000 | 0.56 | 0.11 | 0.12 | ø50 | 0.4 (Standard) 0.15 (With power-saving circuit) |

| SJ3000A Large flow type | 0.76 | 0.19 | 0.21 | ø63 | 0.4 (Standard) 0.15 (With power-saving circuit) |

| SJ4000 | 2.61 | 0.20 | 0.68 | ø80 | 0.4 (Standard) 0.15 (With power-saving circuit) |

Pulse Blow Unit PU

Air Blowing Equipment » Air Blowing Equipment-

・Intermittent pulse blow improves removal efficiency by 35% compared

with continuous blow.

・CO2 emissions (Air consumption): 50% reduction

・Possible to adjust operating frequency

・External power supply is unnecessary.

A pulse blow is possible by the air supply.

・Low pressure loss is achieved.

A large effective area (10.3 mm2) helps reduce the air consumption.

・Possible to use it with its bracket mounted

・Combined use with a blow gun

・Compact, Lightweight

Weight: 47g

Volume: 59.4mm×24mm×28mm

| Series | Fluid | Port size | Operating pressure range | Frequency adjustment range |

|---|---|---|---|---|

| PU20 | Air | IN side port: R1/4 (male thread), OUT side port: Rc1/4 (female thread) | 0.3 to 0.7MPa | 5 to 10Hz |

Air Gripper for Collaborative Robots/Long Stroke Type RMHF2

Rotary Actuators/Air Grippers » Parallel Type Air GrippersRotary Actuators/Air Grippers » Air Gripper Unit for Collaborative Robots

Air Gripper for Collaborative Robots » Air Grippers

-

・Select from 3 types of tool changer.

Simple operation allows for easy tool changing.

Clamp type (Manual override), One-push type (Manual override) [New],

Auto type [New], Tool holder [New]

・Unitization of the peripheral devices required for gripper driving

Operation is possible simply by connecting 1 air supply tube and 1

electrical wire.

Built-in solenoid valve, exhaust throttle valve with silencer, auto switch,

fitting, etc.

・Can be used with the collaborative robots of 12 companies

UNIVERSAL ROBOTS, OMRON/TECHMAN ROBOT, FANUC, YASKAWA

Electric, Mitsubishi Electric, HAN’S ROBOT, KUKA, DOOSAN ROBOTICS,

SIASUN, JAKA, AUBO, ABB

・Air consumption reduced by up to 80%

・Allows for temporary workpiece drop prevention

・The 64 mm long stroke is ideal for a variety of workpieces.

・Height reduced by approx. 35% (Compared with the standard type)

・Actuator position sensor mountable (Option)

(Collaborative robot manufacturer: Compatible with robots from UNIVERSAL

ROBOTS and FANUC CORPORATION)

| Series | Number of fingers | External gripping force [N] | Internal gripping force [N] | Opening/Closing stroke (Both sides) [mm] |

|---|---|---|---|---|

| RMHF2 | 2 | 90 | 90 | 64 |

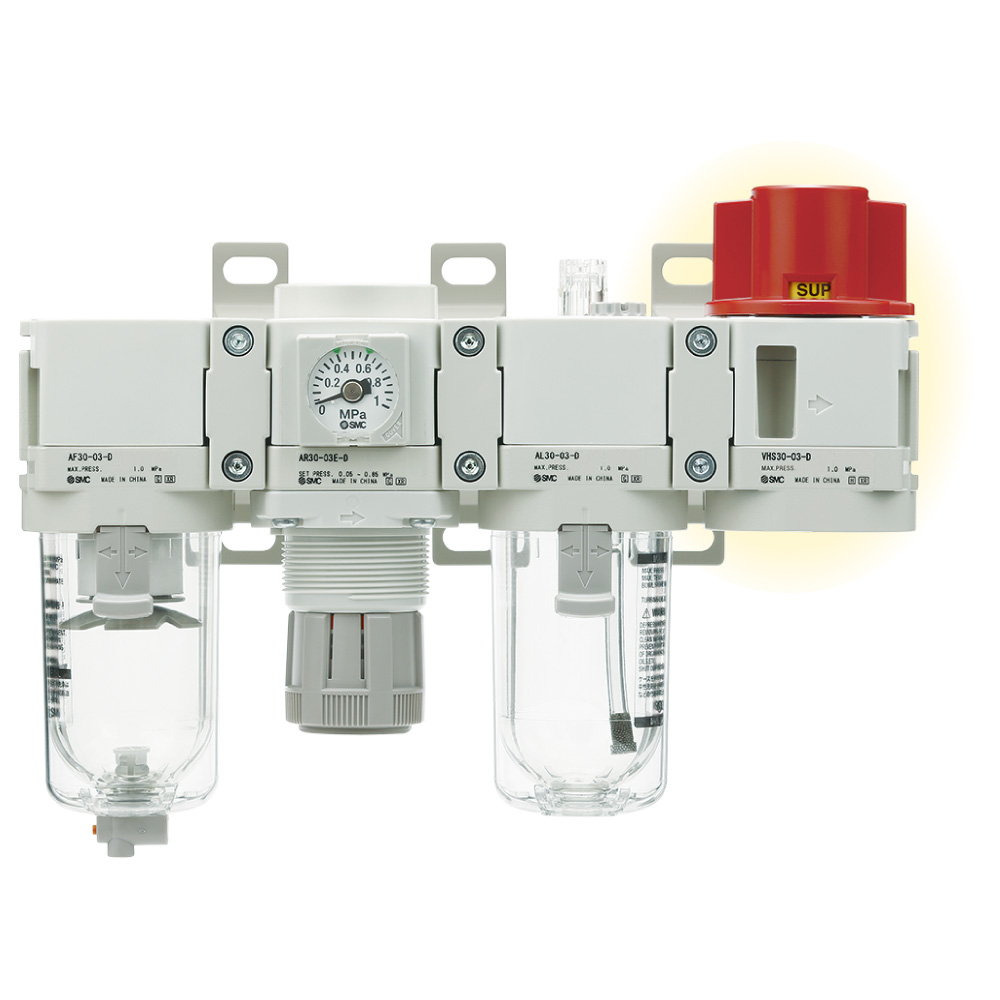

OSHA Standard Compliant Pressure Relief 3-Port Valve with Locking Holes VHS□-D/VHS□W-D

Modular F.R.L./Pressure Control Equipment » Connectable Modular ComponentsModular F.R.L. Units » Modular Connection Compatible Devices

-

・Improved flow rate characteristics: Max. 88% increase (VHS40-04-D)

・Energy saving: Zero blow-by of the air during switching of the handle

・OSHA (Occupational Safety and Health Administration) standard

compliant

・Lower pressure drop contributing to energy saving

Pressure drop reduced by up to 73%

Safety Instructions F.R.L. Units/Precautions Product Selection Guide

Green Procurement (RoHS) Connectable Modular Components (Catalog)

Green Procurement (RoHS) Connectable Modular Components (Catalog)

| Series | Port size | Applicable combinations |

|---|---|---|

| VHS20 (W) -D | 1/8,1/4 | AC20-D |

| VHS30 (W) -D | 1/4,3/8 | AC30-D |

| VHS40 (W) -D | 1/4,3/8,1/2 | AC40-D |

| VHS40 (W) -06-D | 3/4 | AC40-06-D |

| VHS50 (W) -D | 3/4,1 | AC50-D, AC60-D |

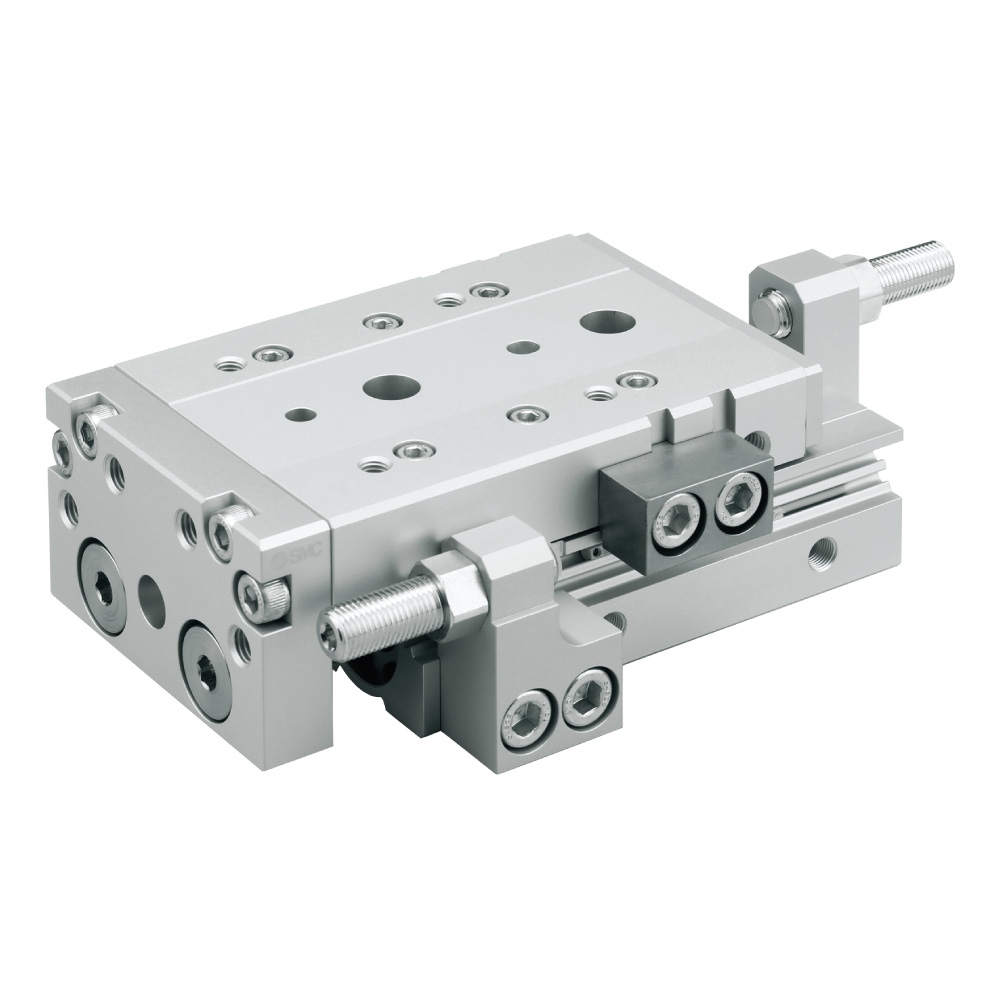

Air Slide Table/High Rigidity Type MXQ32-X2600

Air Cylinders » Table Cylinders-

・75, 100, 125, and 150 mm strokes have been added. [New]

・A linear guide with a 4-row circular arc groove for high rigidity and high

precision

・Table displacement: Reduced by 50% (0.022 mm → 0.011 mm)

・Max. load weight: 16 kg

・Aluminum table: Load weight increased by reducing the weight of

moving parts

・Integrated pilot port, stroke adjuster, and auto switch on 1 side allows for

improved operability

Safety Instructions Actuators/Precautions Auto Switches/Precautions

Model Selection/Technical Data Made to Order Common Specifications

Green Procurement (RoHS)

Model Selection/Technical Data Made to Order Common Specifications

Green Procurement (RoHS)

| Type | Series | Action | Bore size (mm) |

|---|---|---|---|

| Standard High rigidity type | MXQ32-X2600 | Double acting | 32 |