Product Information »

WEB Catalog

IN_PROD_346

» Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other)

» Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems

Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems

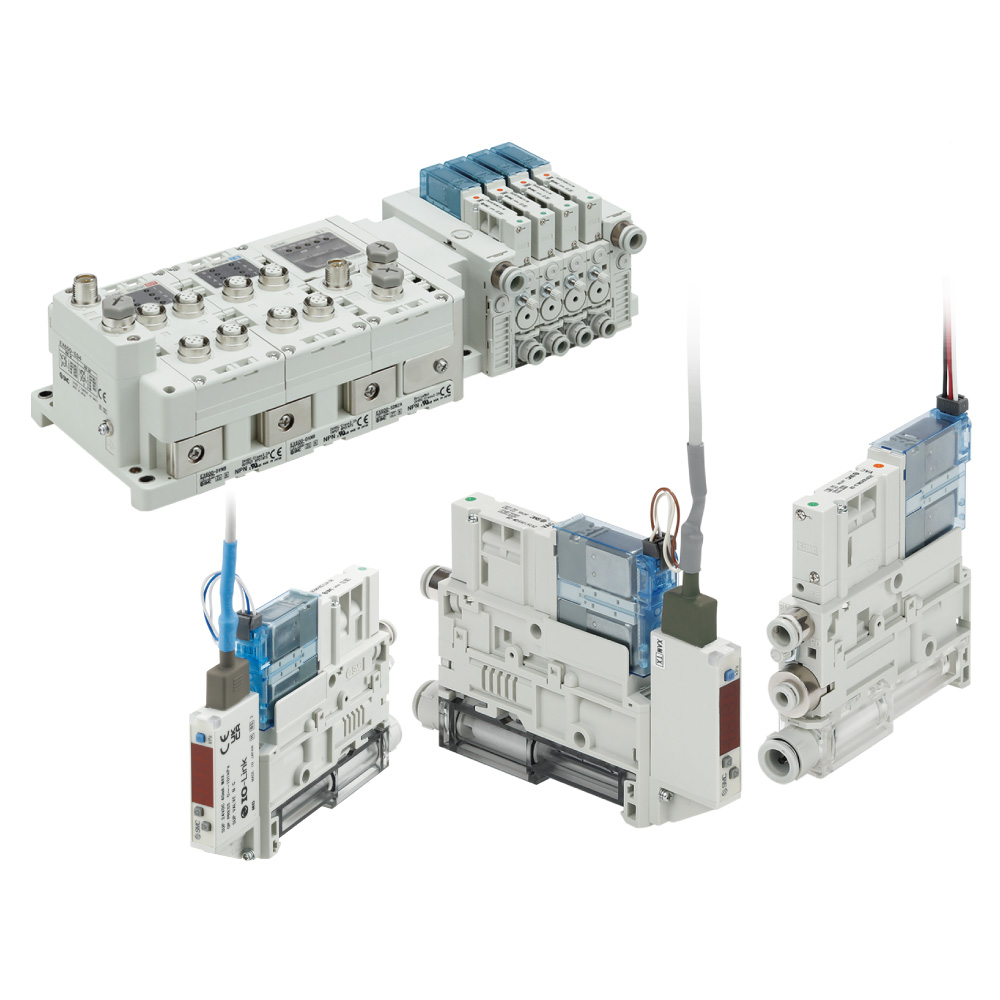

Vacuum Unit (Vacuum Generators) ZK2□A

-

・Supply valve: An N.O. specification has been added.

Can hold vacuum∗ even when the power goes out or is turned off

Prevents the sudden dropping of workpieces∗

∗ Supposing the supply pressure is being maintained

・An IO-Link compatible pressure switch has been added.

Allows for ejector control with a single communication line

Reading of the device information and parameter batch settings are

possible.

・Compatible with ejector systems and vacuum pump systems

・Energy saving ejector

Air supply is cut-off when vacuum is reached.

Air consumption: 93% reduction (Under SMC’s measurement conditions)

・More efficient ejector: Suction flow increased by 50% (Compared to other

SMC 1-stage ejectors)

・Energy saving efficiency: 93% reduction

・Improved low noise and suction flow by adoption of a high-noise

reduction silencer

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZK2□07 | 0.7 | 29 | 24 | 2 to 40 | ZK2□00 |

| ZK2□10 | 1.0 | 44 | 40 | 2 to 50 | ZK2□00 |

| ZK2□12 | 1.2 | 61 | 58 | 2 to 125 | ZK2□00 |

| ZK2□15 | 1.5 | 67 | 90 | 2 to 150 | ZK2□00 |

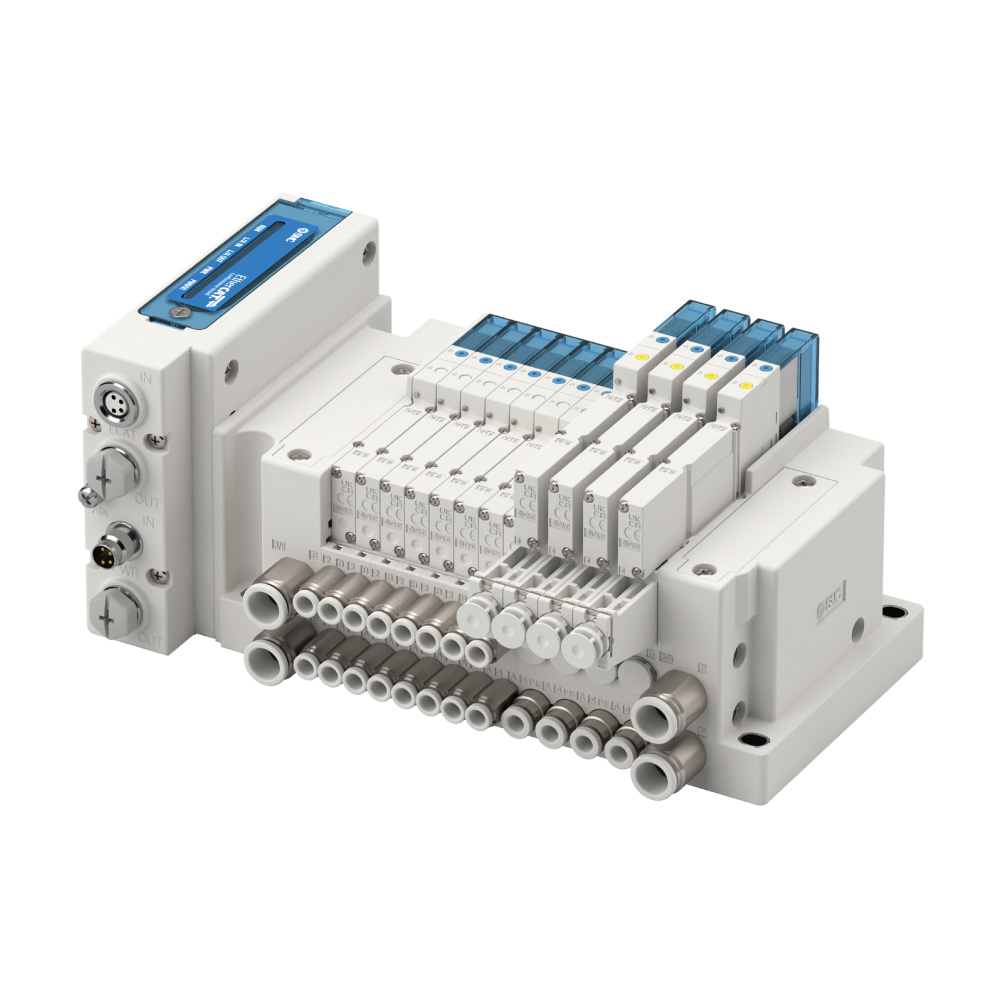

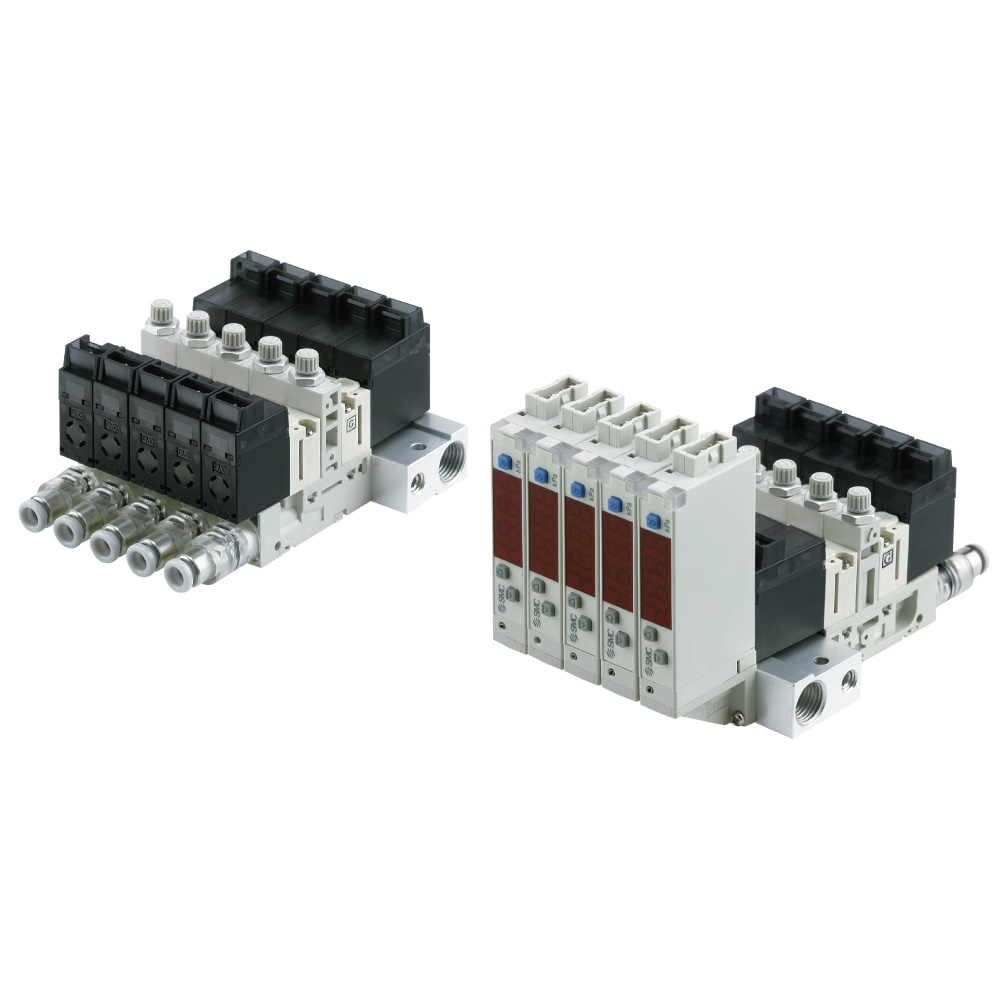

Valve Manifold Integrated with Ejector System JSY1000-E

-

・Spacer type ejector with additional high-noise reduction silencer [New]

・A vacuum release flow adjustment unit has been added.

・Compact all-in-one manifold

The devices have been integrated into one for applications in which an

actuator and vacuum suction are used together.

・EtherCAT®,IO-Link [New],PROFINET® [New],EtherNet/IP™ [New] compatible

・Wiring/piping saving through use of all-in-one manifold

・Installation area: 64% reduction

・Weight: 42% reduction

・Energy saving function

CO2 emissions (Air consumption): 90% reduction

▶IO-Link Master

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Flow rate characteristics 4/2→3/5 (A/B→E) C [dm3/(s・bar)] | Flow rate characteristics 4/2→3/5 (A/B→E) b | Applicable cylinder size | Power consumption (W) |

|---|---|---|---|---|

| JSY1000-E | 0.91 | 0.48 | φ40 | 0.2 (With power-saving circuit) |

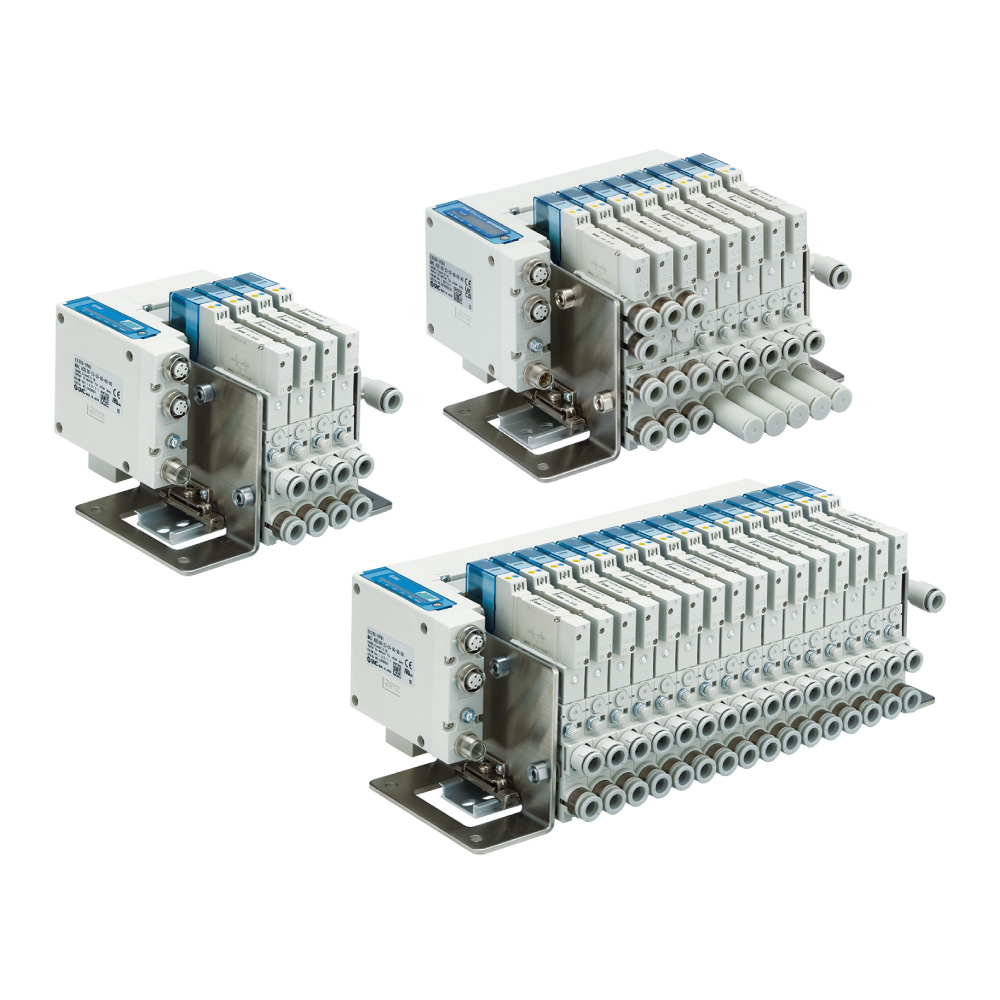

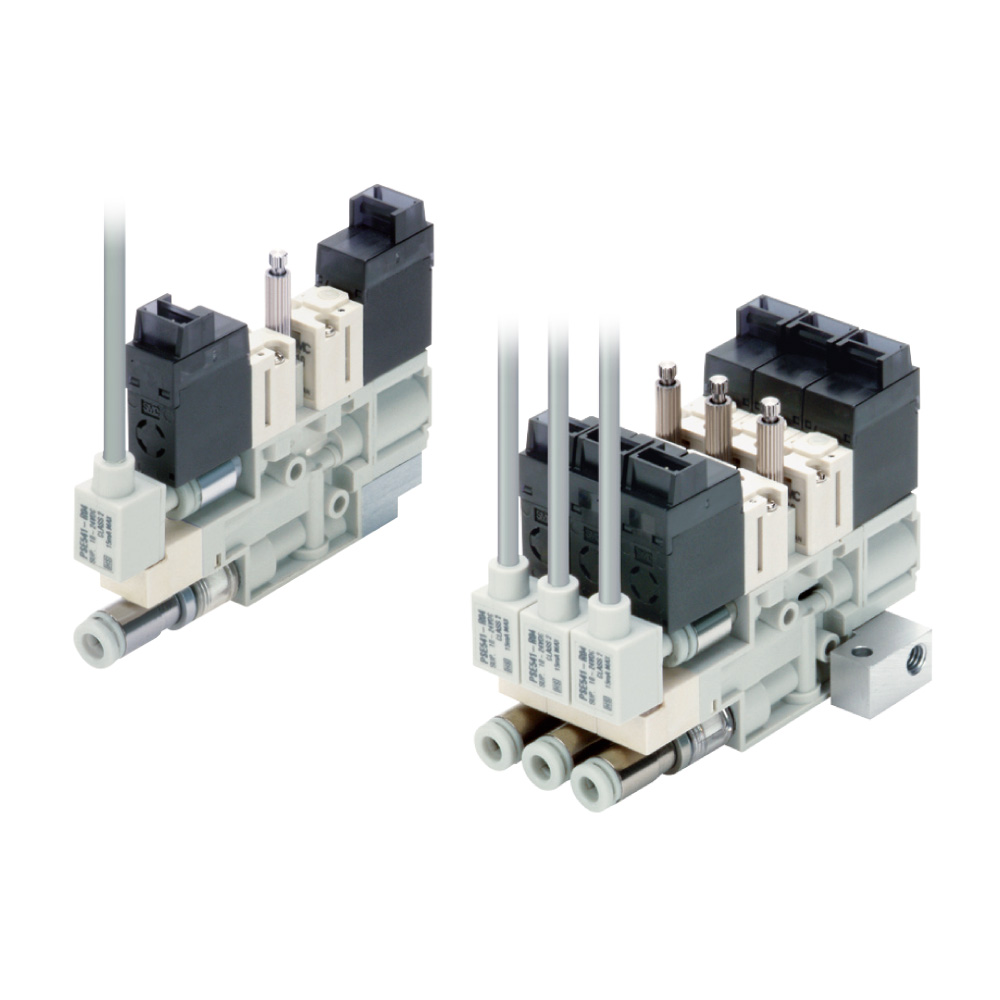

Vacuum Manifold for Fieldbus System ZKJ

-

・Vacuum pads and actuator driving can be controlled with a single

manifold [New]

・Positive pressure unit [New]

5-port solenoid valve

・Vacuum unit

Energy saving ejector Air consumption: 92% reduction

・Fieldbus compatible

Space saving: Requires no separate input/output units

Reduced wiring time

Compatible protocols: PROFINET, IO-Link, EtherNet/IP, EtherCAT

・Exhaust sealing function

Quick workpiece release

・4 stations/8 stations/12 stations/16 stations manifold compatible

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|

| ZKJ07 | 0.7 | 31 | 26 |

| ZKJ10 | 1.0 | 53 | 48 |

| ZKJ12 | 1.2 | 63 | 68 |

| ZKJ15 | 1.5 | 74 | 102 |

Compact Vacuum Unit ZQ□A

-

・Vacuum pressure switch with energy saving function

Air consumption: 90% reduction (Based on SMC’s measurement

conditions)

Power consumption: 60% reduction [1 W (Existing model) → 0.4 W]

Vacuum release pressure: From 0 MPa [From 0.3 MPa (Existing model) →

From 0 MPa]

Copy function: Reduced setting labor, Minimized risk of setting mistakes

・Compatible with ejector systems and vacuum pump systems

・IO-Link compatible

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZQ05 | 0.5 | 5 | 15 | 2 to 13 | ZQ000□ |

| ZQ07 | 0.7 | 10 | 25 | 2 to 20 | ZQ000□ |

| ZQ10 | 1.0 | 22 | 47 | 2 to 32 | ZQ000□ |

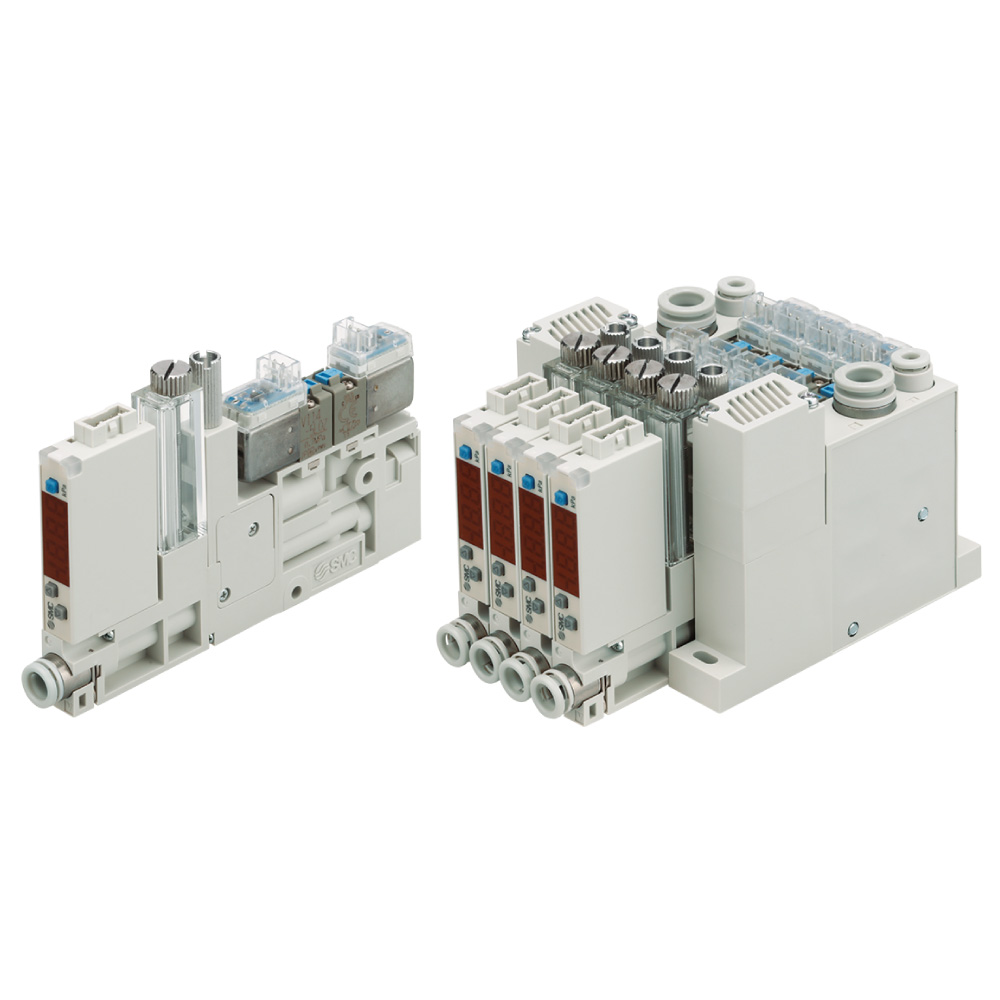

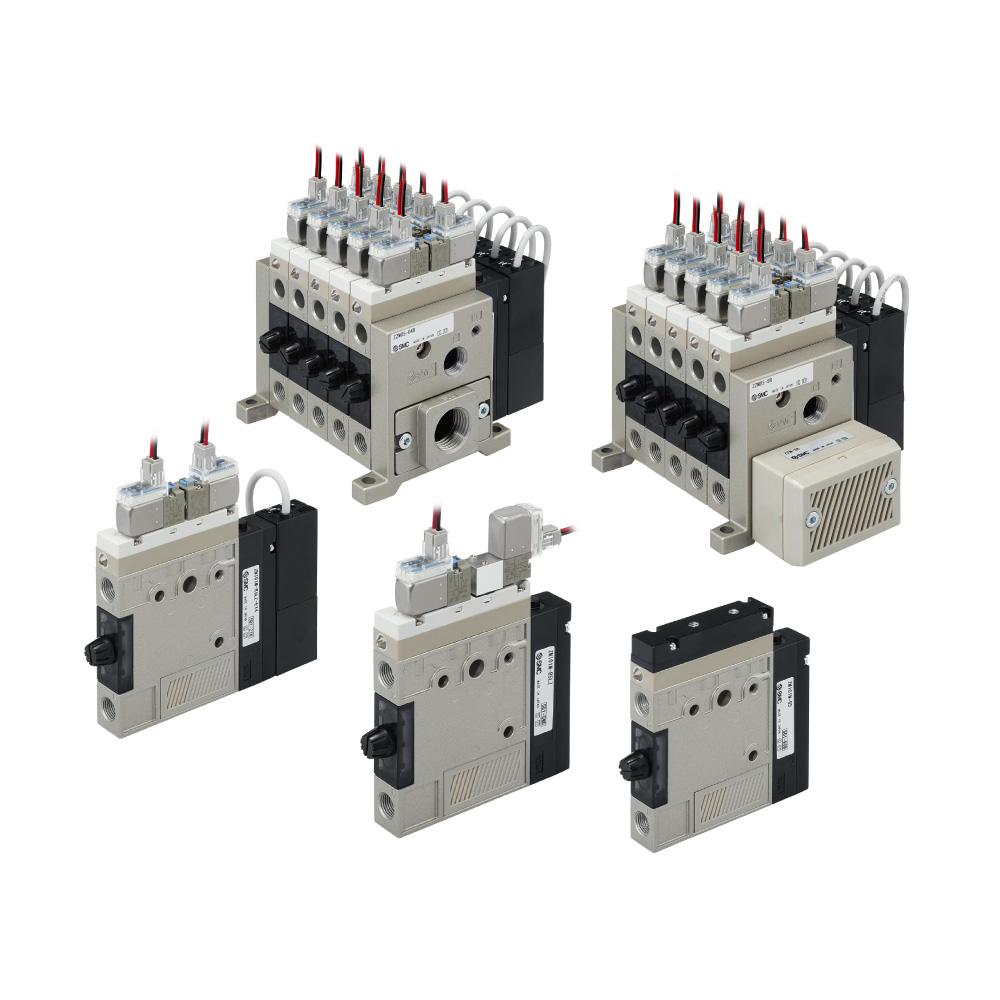

Large Size Vacuum Module (Vacuum Generators) ZR

-

・Compatible with ejector systems and vacuum pump systems

・Necessary functions can be combined through a modular design.

・Double solenoids provide a self-holding function.

・Adaptable to manifold applications

・Functions such as a digital vacuum switch or a solenoid valve can be selected.

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZR110 | 1.0 | 25 | 53 | 2 to 32 | ZR100 |

| ZR113 | 1.3 | 42 | 86 | 2 to 50 | ZR100 |

| ZR115 | 1.5 | 63 | 102 | 2 to 100 | ZR100 |

| ZR118 | 1.8 | 74 | 155 | 2 to 125 | ZR100 |

| ZR120 | 2.0 | 95 | 194 | 2 to 150 | ZR100 |

Compact Vacuum Unit (Vacuum Generators) ZB

-

・Compatible with ejector systems and vacuum pump systems

・Quick response: Response time of the valve 5 ms, vacuum response time

28 ms

・Energy saving: Air consumption reduced by 17%, Vacuum pressure

reached increased by 21%

・Compact/Lightweight: 46 g

・With vacuum pressure switch

Can copy to up to 10 switches simultaneously

・IO-Link compatible

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZB03 | 0.3 | 2 | 3.5 | 2 to 8 | ZB00 |

| ZB04 | 0.4 | 3.5 | 6.5 | 2 to 10 | ZB00 |

| ZB05 | 0.5 | 4.5 | 10 | 2 to 13 | ZB00 |

| ZB06 | 0.6 | 7 | 18 | 2 to 20 | ZB00 |

Compact Vacuum Ejector (Vacuum Generators) ZA

-

・Total width: 9.9 mm, Total length: 72.9 mm, Total height: 52.5 mm,

Weight: 50 g

・Can be installed on moving parts

・Improved response through the shortening of the length of the tube to the pad

・Adaptable to manifold applications

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) |

|---|---|---|---|---|

| ZA105 | 0.5 | 4 | 12 | 2 to 13 |

| ZA107 | 0.7 | 8 | 28 | 2 to 20 |

Vacuum Ejector (Vacuum Generators) ZM

-

・Valves and switches are unitized.

・Adaptable to manifold applications

・Maximum absorption flow rate has been increased by 40%.

・Max. vacuum pressure: −84 kPa

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) |

|---|---|---|---|---|

| ZM05 | 0.5 | 15 | 17 | 2 to 16 |

| ZM07 | 0.7 | 23 | 33 | 2 to 25 |

| ZM10 | 1.0 | 38 | 60 | 2 to 32 |

| ZM13 | 1.3 | 44 | 85 | 2 to 40 |

| ZM15 | 1.5 | 45 | 110 | 2 to 50 |

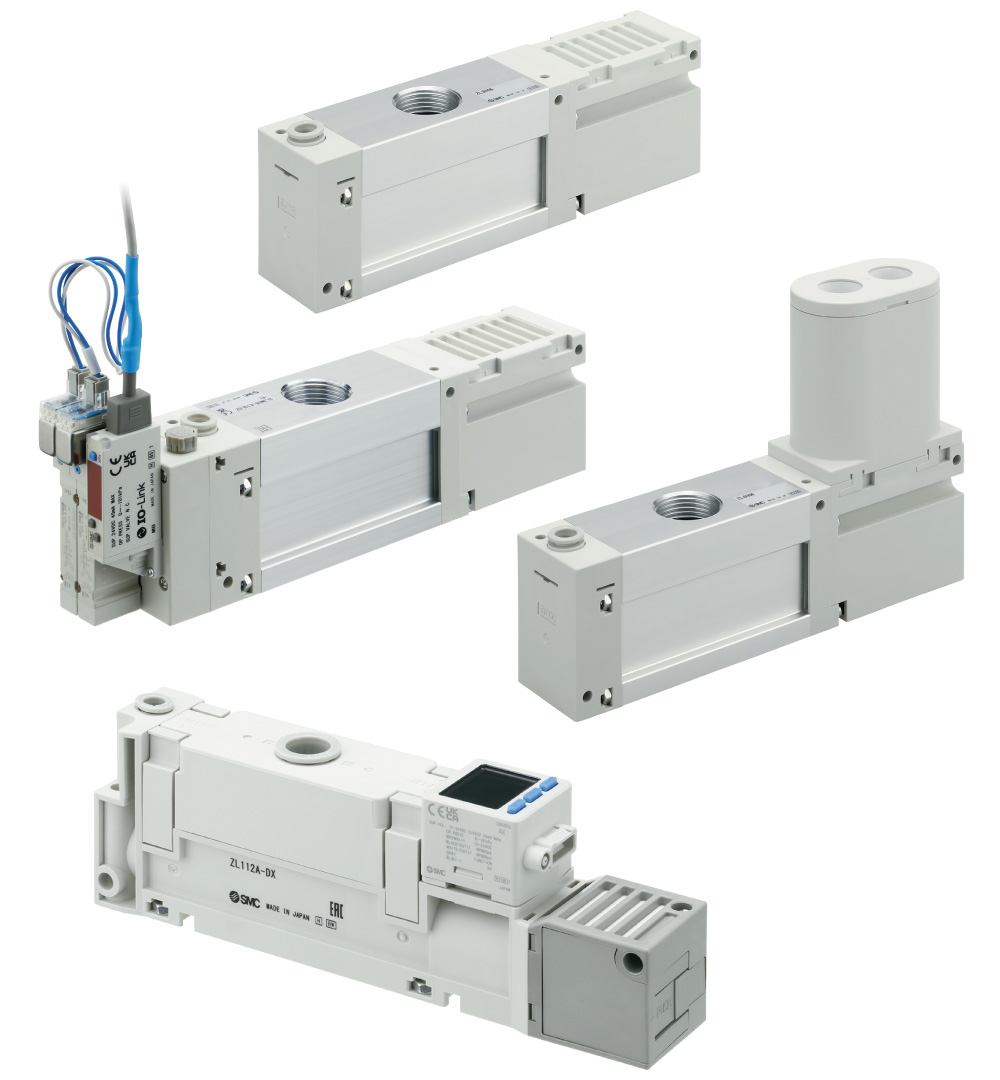

Multistage Ejector ZL1/ZL3/ZL6

-

・An IO-Link compatible vacuum pressure switch has been added. (ZL3,

ZL6) New

Allows for ejector control with a single communication line

Reading of the device information and parameter batch settings are

possible.

・Max. suction flow rate: 3 types available: 100, 300, and 600 L/min (ANR)

・Air consumption: 91% reduction (ZL3, ZL6)

Reduced by the pressure switch for vacuum with energy saving function

and efficient ejectors

・Weight: Max. 60% reduction [ZL112 (Existing model): 450 g → ZL1: 180 g]

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|

| ZL1 | 1.2 | 100 | 57 |

| ZL3M | 1.9 | 300※1 | 150 |

| ZL3H | 1.5 | 300※1 | 135 |

| ZL6M | 1.9×2 | 600※1 | 300 |

| ZL6H | 1.5×2 | 600※1 | 270 |

List

List Picture

Picture