There were 709 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Electric Actuator/High Rigidity Slider Type LEJ

Electric Actuators/Cylinders » Motorless Type-

・Various servo motors can be mounted due to the addition of the motorless type.

・Compatible motors:

Mitsubishi Electric Corporation, YASKAWA Electric Corporation,

SANYO DENKI CO., LTD., OMRON Corporation, Panasonic Corporation,

FANUC CORPORATION, NIDEC INSTRUMENTS,

KEYENCE CORPORATION, FUJI ELECTRIC CO., LTD., MinebeaMitsumi Inc.,

Shinano Kenshi Co., Ltd., ORIENTAL MOTOR Co., Ltd., FASTECH Co., Ltd.,

Rockwell Automation, Inc. (Allen-Bradley), Beckhoff Automation GmbH,

Siemens AG, Delta Electronics, Inc., ANCA Motion

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

| Specification | Model | Stroke (mm) | Work load (kg) | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Motorless Ball screw drive | LEJS40 | 200 to 1200 | Max. 55 | Max. 1800 | 8, 16, 24 |

| Motorless Ball screw drive | LEJS63 | 300 to 1500 | Max. 85 | Max. 1800 | 10, 20, 30 |

Electric Actuator/High Rigidity Slider Type, Ball Screw Drive 11-LEJS

Clean Series/Low-Particle Generation » Electric ActuatorsElectric Actuators/Cylinders » Environment

Clean Series

・Low profile/Low center of gravity: Height reduced by approx. 36% (Reduced by 32 mm)

・Max. work load: 85 kg

・Positioning repeatability: ±0.02 mm

・Max. acceleration/deceleration: 20000 mm/s2

・Clean room specification

・Motorless specification is available. Click here for details

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions Features

Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

CE/UL-compliance List

Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

CE/UL-compliance List

| Specification | Model | Stroke (mm) | Work load (kg) Horizontal | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| AC servo motor | 11-LEJS40 | 200 to 1200 | Max. 55 | Max. 1200 | 8,16 |

| AC servo motor | 11-LEJS63 | 300 to 1500 | Max. 85 | Max. 1200 | 10,20 |

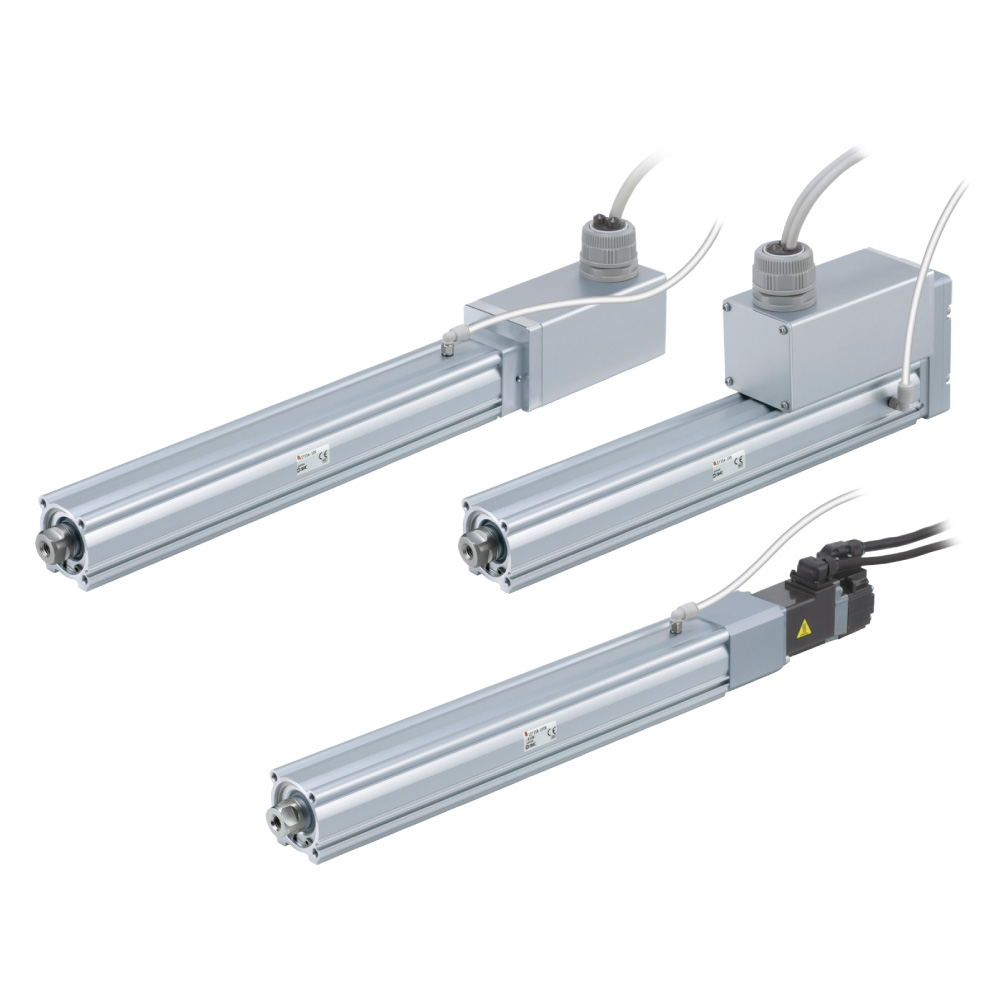

Electric Actuator/Rod Type Dust-tight/Water-jet-proof (IP65 Equivalent) LEY-X5

Electric Actuators/Cylinders » Environment

-

・Enclosure: IP65 equivalent

・Max. stroke: 500 mm

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

CE/UL-compliance List Actuator Cable I/O Cable

CE/UL-compliance List Actuator Cable I/O Cable

| Specification | Model | Stroke (mm) | Pushing force (N) | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Step motor (Servo/24 VDC) | LEY25-X5 | 30 to 400 | Max. 452 | Max. 400 | 3, 6, 12 |

| Step motor (Servo/24 VDC) | LEY32-X5 | 30 to 500 | Max. 707 | Max. 400 | 4, 8, 16 |

| Servo motor (24 VDC) | LEY25A-X5 | 30 to 400 | Max. 130 | Max. 400 | 3, 6, 12 |

| AC servo motor | LEY25S-X5 | 30 to 400 | Max. 485 | Max. 900 | 3, 6, 12 |

| AC servo motor | LEY32S-X5 | 30 to 500 | Max. 588 | Max. 1200 | 5, 10, 20 |

| AC servo motor | LEY63□□-□P | 100 to 800 | Max. 1910 | Max. 1000 | 5, 10, 20 |

| AC servo motor (In-line motor type) | LEY25DS-X5 | 30 to 400 | Max. 485 | Max. 900 | 3, 6, 12 |

| AC servo motor (In-line motor type) | LEY32DS-X5 | 30 to 500 | Max. 736 | Max. 1000 | 4, 8, 16 |

| AC servo motor (In-line motor type) | LEY63D□□-□P | 100 to 800 | Max. 1910 | Max. 1000 | 5, 10, 20 |

Programless Controller LECP1

Electric Actuators/Cylinders » Controllers/Drivers

-

・No programming required

Capable of setting up an electric actuator operation without using a PC or

teaching box

・Speed/acceleration 16-level adjustment

・Compatible with actuators with locks

・3-level pushing force settings

The LECP1 and LECP2 series programless controllers are to be discontinued

as of the end of May 2025.

Consider selecting the JXC51/61 series single-axis controller instead, as it

has interchangeable functions.

* The most recent versions of the JXC51/61 series (Ver. 3.60 and up) and the

ACT Controller 2 setting software (Ver. 1.5.0.0) are required in order to use

the LECP1/LECP2 mode.

▶Click here for details.

Safety Instructions Electric Actuators/Precautions Features

Series Variations Simplified Selection Flow Chart Wiring Method

Green Procurement (RoHS)

Series Variations Simplified Selection Flow Chart Wiring Method

Green Procurement (RoHS)

| Type | Series | Compatible motor | Power supply voltage | Parallel I/O Input | Parallel I/O Output | Number of step data |

|---|---|---|---|---|---|---|

| Programless type | LECP1 | Step motor (Servo/24 VDC) | 24 VDC ±10% | 6 (Photo-coupler isolation) | 6 (Photo-coupler isolation) | 14 points |

Electric Gripper 2-Finger Type (F Type) LEHF

Electric Actuators/Cylinders » Grippers

-

・Easy setting: Data can be set with only 2 items, position and force.

The controller is already set with the data of the actuator.

(The actuator and controller are provided as a set.)

・Equipped with a drop prevention function

(All series come equipped with a self-lock mechanism.)

・The self-lock mechanism reduces power consumption.

・Equipped with a gripping check function

・It is possible to set the position, speed, and force. (64 points)

Note) ( ): For long strokes

Safety Instructions Electric Actuators/Precautions Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS) CE/UL-compliance List Actuator Cable I/O Cable

| Series | Body size | Open and close stroke/ both sides (mm) | Gripping force [N] Basic | Gripping force [N] Compact | Opening and closing speed (mm/s) |

|---|---|---|---|---|---|

| LEHF | 10 | 16(32)Note) | 3 to 7 | 3 to 7 | 5 to 80 |

| LEHF | 20 | 24(48)Note) | 11 to 28 | 11 to 28 | 5 to 100 |

| LEHF | 32 | 32(64)Note) | 48 to 120 | 48 to 120 | 5 to 100 |

| LEHF | 40 | 40(80)Note) | 72 to 180 | 72 to 180 | 5 to 100 |

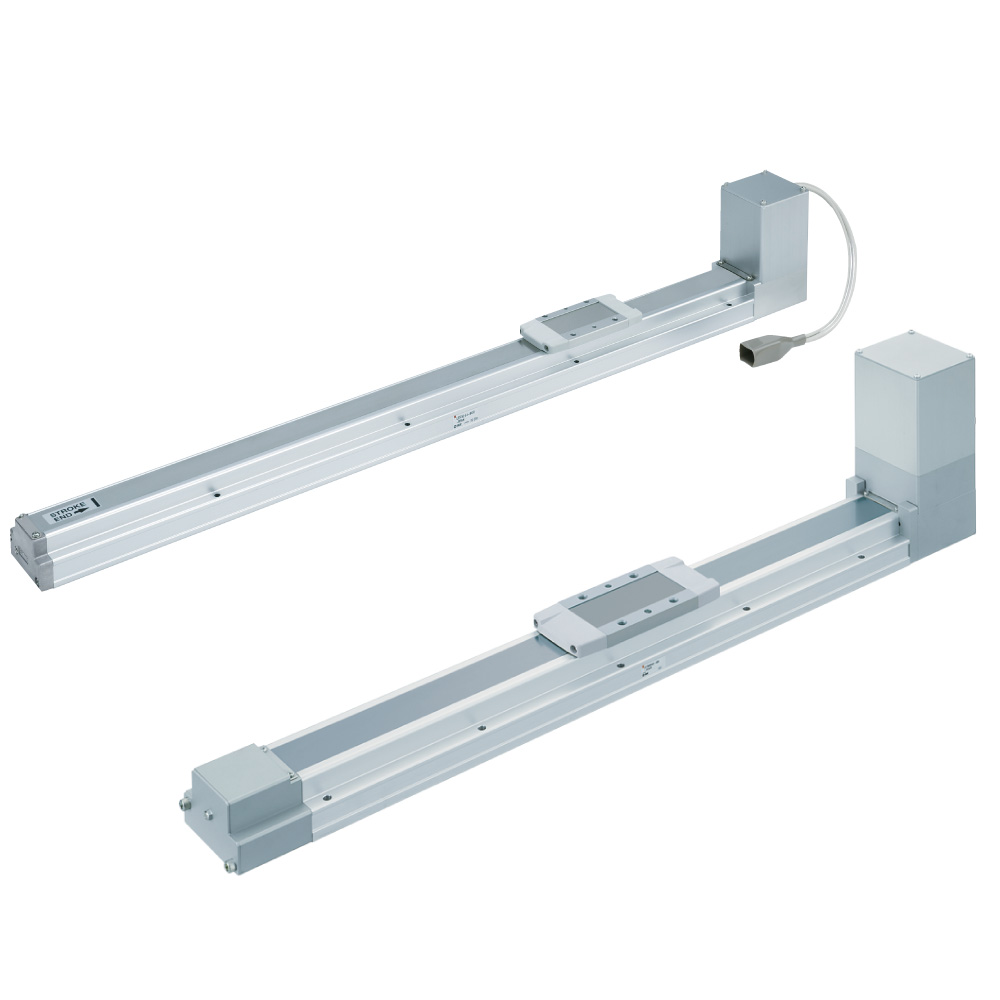

Electric Actuator/Slider Type, Belt Drive LEFB

Electric Actuators/Cylinders » Slider Type

-

LEFB Series Step Motor (Servo/24 VDC), Servo Motor (24 VDC)

・Max. stroke: 2000 mm

・Max. speed: 2000 mm/s

・Positioning repeatability: ±0.08 mm

LEFB Series AC Servo Motor

・Max. speed: 2000 mm/s

・Max. stroke: 3000 mm

・Max. acceleration/deceleration: 20000 mm/s2

・Pulse input type/With internal absolute encoder

・Positioning repeatability: ±0.06 mm

・Motorless specification is available. Click here for details

・Compatible drivers: Click here for LECSS-T,LECY□

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

CE/UL-compliance List Actuator Cable I/O Cable

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

CE/UL-compliance List Actuator Cable I/O Cable

| Specification | Model | Stroke (mm) | Work load (kg) Horizontal | Speed (mm/s) | Equivalent lead (mm) |

|---|---|---|---|---|---|

| Step motor (Servo/24 VDC) | LEFB16 | 300 to 1000 | 1 | 48 to 1100 | 48 |

| Step motor (Servo/24 VDC) | LEFB25 | 300 to 2000 | 10 | 48 to 1400 | 48 |

| Step motor (Servo/24 VDC) | LEFB32 | 300 to 2000 | 19 | 48 to 1500 | 48 |

| Servo motor (24 VDC) | LEFB16A | 300 to 1000 | 1 | 5 to 2000 | 48 |

| Servo motor (24 VDC) | LEFB25A | 300 to 2000 | 2 | 5 to 2000 | 48 |

| AC servo motor | LEFB25S | 300 to 2000 | 5 | Max. 2000 | 54 |

| AC servo motor | LEFB32S | 300 to 2500 | 15 | Max. 2000 | 54 |

| AC servo motor | LEFB40S | 300 to 3000 | 25 | Max. 2000 | 54 |

Electric Actuator Slide Table/High Precision Type LESYH

Electric Actuators/Cylinders » Slide Tables-

・Improved positioning repeatability due to the adoption of a ball screw

drive.

Positioning repeatability: ±0.01 mm

・Lost motion: 0.1 mm or less

・Increased vertical work load: 5 times or more

・Motorless type

Can be used with your current motor and driver!

Safety Instructions Electric Actuators/Precautions Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS) CE/UL-compliance List

| Spec. | Model | Stroke (mm) | Work load (kg) Horizontal | Work load (kg) Vertical | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|---|

| Battery-less absolute (Step motor 24 VDC) | LESYH8 | 50,75 | Max. 2 | Max. 6 | Max. 400 | 2.5,5,10 |

| Battery-less absolute (Step motor 24 VDC) | LESYH16 | 50,100 | Max. 8 | Max. 12 | Max. 400 | 6,12 |

| Battery-less absolute (Step motor 24 VDC) | LESYH25 | 50,100,150 | Max. 12 | Max. 20 | Max. 400 | 10,20 |

| AC servo motor | LESYH16 | 50,100 | Max. 8 | Max. 12 | Max. 400 | 6,12 |

| AC servo motor | LESYH25 | 50,100 | Max. 12 | Max. 20 | Max. 400 | 10,20(Parallel) 8,16(In-line) |

Battery-less Absolute Encoder Type

Electric Actuator/High Performance Slider Type LEFS□G

Electric Actuators/Cylinders » Battery-less Absolute Encoder Type

-

・Reduces cycle time

Cycle time: Reduced by 39% (0.57 s ← 0.93 s) compared with the existing

model

∗ When LEFS25GH-400 is operated from 0 to 400 mm

Acceleration/Deceleration: 10000 mm/s2 (334% increase compared with

the existing model)

Max. speed: 1500 mm/s (Improved by 25% compared with the existing

model)

・Battery-less absolute encoder compatible

Easy operation restart after recovery of the power supply

Maintenance labor can be reduced as the product does not require

the use of batteries.

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions

Green Procurement (RoHS)

Green Procurement (RoHS)

| Specification | Model | Stroke (mm) | Work load (kg) Horizontal | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| High performance Battery-less absolute (Step motor/24 VDC) | LEFS16G | 50 to 500 | Max. 15 | Max. 800 | 5,10 |

| High performance Battery-less absolute (Step motor/24 VDC) | LEFS25G | 50 to 800 | Max. 40 | Max. 1500 | 6,12,20 |

| High performance Battery-less absolute (Step motor/24 VDC) | LEFS32G | 50 to 1000 | Max. 68 | Max. 1300 | 8,16,24 |

| High performance Battery-less absolute (Step motor/24 VDC) | LEFS40G | 150 to 1200 | Max. 75 | Max. 1200 | 10,20,30 |

Air Gripper Unit for Collaborative Robots JMHZ2-X7400B-ASSISTA

for the Mitsubishi Electric Corporation MELFA ASSISTA Series

Rotary Actuators/Air Grippers » Air Gripper Unit for Collaborative Robots-

・Compact, lightweight product with high gripping force due to air operation

・High rigidity and high precision due to its guide-integrated construction

Repeatability: ±0.01 mm due to the adoption of a high-precision linear guide

Higher rigidity due to the adoption of a linear guide of the higher rigidity and precision

・Operate by simply connecting 1 air supply tube and an electrical wiring M12 connector.

・Integrated solenoid valve, speed adjustment mechanism, and auto switch

・A split protective cover for easy air gripper maintenance

・Standards: ISO 9409-1-31.5-4-M5

| Type | Series | Cylinder bore size (mm) |

|---|---|---|

| For Collaborative Robots | JMHZ2-16D-X7400B-ASSISTA | 16 |

Air Cylinder C76

ISO Products » CylindersAir Cylinders » ISO Cylinders

| Type | Series | Action | Bore size (mm) |

|---|---|---|---|

| Standard | C76 | Double acting, Single rod | 32, 40 |

| Standard | C76 | Double acting, Double rod | 32, 40 |

| Standard | C76 | Single acting (Spring return/Extended) | 32, 40 |

| Non-rotating rod | C76K | Double acting, Single rod | 32, 40 |

| Non-rotating rod | C76K | Single acting, (Spring return/Extended) | 32, 40 |

| Direct mount | C76R | Double acting, Single rod | 32, 40 |