There were 21 hits in the keyword search.

Fittings for Special Environments HF2-/HF2A (Compatible)/HF2B (Compatible)

Equipment for the Food Manufacturing Industry » Fittings and Tubing| Series | Model | Specification |

|---|---|---|

| EHEDG Compliant Fittings | KFG2H□-E | HF2B Compatible∗ |

| Clean Design Fittings | KFG2H□-C | HF2B Compatible∗ |

| US FDA Compliant Fittings | KQG2-F/KQB2-F/KFG2-F | HF2B Compatible∗ |

Tool Changer One-push Type/Clamp Type RMTM

Grippers for Collaborative Robots » Air GrippersGrippers for Collaborative Robots » Tool Changer

-

·2 types of manual tool changers

· One-push Type

Tools can be attached/removed by the push of a button (no tools

required).

Work load: 10 kg

Repeatability: ±0.01 (Position reproducibility)

· Clamp Type

Tools can be attached/removed by clamper bolts (2 pcs).

Work load: 20 kg

Repeatability: ±0.02 (Position reproducibility)

·Standards: ISO9409-1-50-4-M6 compliant

Compatible with the flanges of most major collaborative robots

·Compact, Lightweight

| Type | Series | Work load (kg) | Repeatability (Position reproducibility) |

|---|---|---|---|

| One-push type | RMTM1 | 10 kg | ±0.01 |

| Clamp type | RMTM2 | 20 kg | ±0.02 |

Manifold Controller JXD1-M□

Electric Actuators/Cylinders » Controllers/DriversElectric Actuators/Cylinders » Manifold Controller/Manifold Controller Compatible Electric Actuator

-

· Up to 16 axes can be connected

Max. 8 driver units can be connected

· Fanless design (no cooling fan)

No cooling fan = No need to worry about fan replacement

· Operating temperature range: 0 to 55°C

· Communication protocol

CC-Link

EtherNet/IP™

EtherCAT®

PROFINET®

· Cables, etc. can be attached from the front.

| Series | Compatible motor | Power supply voltage | Communication protocol | Connecting actuator | Number of driver units | Number of axes |

|---|---|---|---|---|---|---|

| JXD1-M□ | Battery-less absolute (Step motor 24 VDC) | 24 VDC ±10% | CC-Link EtherNet/IP™ therCAT® PROFINET® | LE2□ | Max. 8 units | Max. 16 axes |

Membrane Nitrogen Generator IN778-1/IN778-2

Gas Generator » Gas Generator-

・Nitrogen enriched air purification is easily possible with only

a compressed air supply.

・Nitrogen concentration: Max. 99.9 or more/ Outlet air flow rate: 20 L/min

(ANR)※

※Inlet air pressure: 0.7 MPa, Inlet air temperature 25°C

・Compact and easy to use at point of use

・No power supply required

・No need for gas cylinder replacement

・Modular connection type

・Outlet side compressed air purity class (Humidity)"2"※

※For IN778-1

| Series | Inlet air conditions | Nitrogen enriched outlet air flow rate L/min(ANR) | Nitrogen concentration % | Proof pressure Mpa | Max. operating pressure Mpa | Min. operating pressure Mpa |

|---|---|---|---|---|---|---|

| IN778-1 | 25℃ 0.7MPa | 20 | 99.9 | 1.5 | 1.0 | 0.3 |

| IN778-2 | 25℃ 0.7MPa | 20 | 98 | 1.5 | 1.0 | 0.3 |

Regulators for Ultra High Purity (UHP) AP/SL/AP/AZ

Process Gas Equipment » Process Gas Equipment

-

・For UHP gas delivery in semiconductor and other clean industries

・Body material: 316L SS secondary remelt or 316L SS

・Electropolished wetted parts

・External metal seal construction

Safety Instructions Process Gas Equipment/Common Precautions Series Variations Valve and Regulator Recommendations Technical Data/Glossary of Terms Green Procurement (RoHS)

| Series | Description | Type | Body material |

|---|---|---|---|

| AP | For Ultra High Purity | Single Stage Regulator | 316L SS secondary remelt |

| AP | For Ultra High Purity | Two Stage Regulator | 316L SS secondary remelt |

| AP | For Ultra High Purity | Pneumatic Actuation Pressure Regulator | 316L SS secondary remelt |

| SL | For Ultra High Purity | Single Stage Regulator | 316L SS secondary remelt |

| AZ | For Ultra High Purity | Single Stage Regulator | SUS316L |

| AZ | For Ultra High Purity | Pneumatic Actuation Pressure Regulator | SUS316L |

| AK | For General Applications | Single Stage Regulator | SUS316 |

| AK | For General Applications | Two Stage Regulator | SUS316 |

| AK | For General Applications | Pneumatic Actuation Pressure Regulator | SUS316 |

| BP | For Ultra High Purity | Back Pressure Regulator | SUS316 |

| BP | For General Applications· | Back Pressure Regulator | SUS316 |

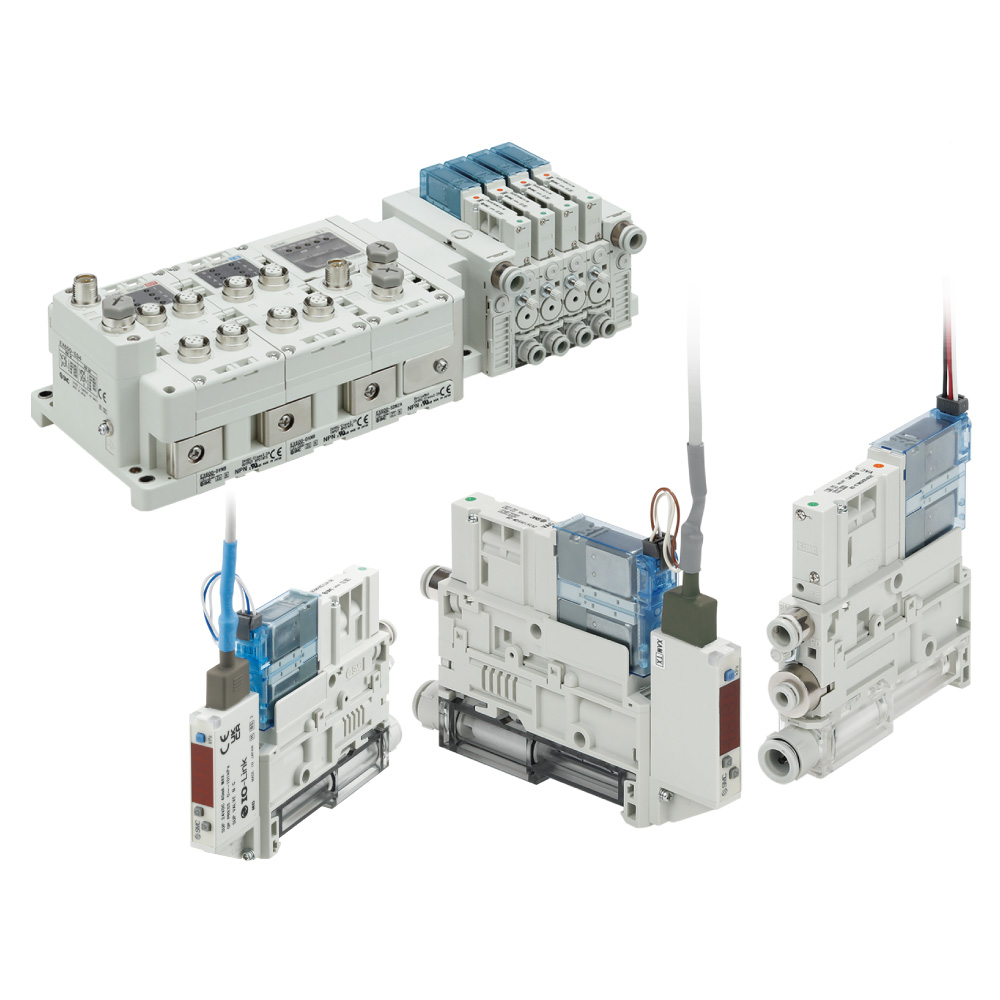

Vacuum Unit (Vacuum Generators) ZK2□A

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems-

・Supply valve: An N.O. specification has been added.

Can hold vacuum∗ even when the power goes out or is turned off

Prevents the sudden dropping of workpieces∗

∗ Supposing the supply pressure is being maintained

・An IO-Link compatible pressure switch has been added.

Allows for ejector control with a single communication line

Reading of the device information and parameter batch settings are

possible.

・Compatible with ejector systems and vacuum pump systems

・Energy saving ejector

Air supply is cut-off when vacuum is reached.

Air consumption: 93% reduction (Under SMC’s measurement conditions)

・More efficient ejector: Suction flow increased by 50% (Compared to other

SMC 1-stage ejectors)

・Energy saving efficiency: 93% reduction

・Improved low noise and suction flow by adoption of a high-noise

reduction silencer

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZK2□07 | 0.7 | 29 | 24 | 2 to 40 | ZK2□00 |

| ZK2□10 | 1.0 | 44 | 40 | 2 to 50 | ZK2□00 |

| ZK2□12 | 1.2 | 61 | 58 | 2 to 125 | ZK2□00 |

| ZK2□15 | 1.5 | 67 | 90 | 2 to 150 | ZK2□00 |

Direct Operated Regulator for 6.0 MPa (Relieving Type) VCHR

Modular F.R.L./Pressure Control Equipment » RegulatorsProcess Valves » 5.0 MPa 2/3 Port Solenoid Valves

Pressure Control Equipment » Regulators

-

・Service life: 10 million cycles

Improved durability in high-pressure environments through the use of a polyurethane elastomer poppet

・Uses NSF-H1 approved grease on guide rings (Sliding parts)

・Improved durability through the use of a metal seal type relief valve

・Uses a special fluororesin seal for sliding parts

Stable unattached response, Not easily affected by pressure

Safety Instructions F.R.L. Units/Precautions Series Variations/Solenoid Valves List

Product Selection Guide Green Procurement (RoHS)

Product Selection Guide Green Procurement (RoHS)

| Series | Model | Type | Port size | Set pressure (MPa) |

|---|---|---|---|---|

| VCHR | VCHR30/40 | Direct operated regulator (Relieving type) | G3/4,1,1 1/2 | 0.5 to 5.0 (Max. operating pressure 6.0) |

Refrigerated Air Dryer IDF □E/F/D

Air Preparation Equipment » Air Dryers

-

* The refrigerated air dryer IDF22E to IDF75E series is to be discontinued.

Please consider selecting an IDF60 to 90 series refrigerated air dryer as a

substitute.

Discontinuation date

IDF22E/IDFA22E: Discontinued

IDF37E/IDFA37E: Scheduled to be discontinued as of the end of

March 2024

IDF55E/IDFA55E: Scheduled to be discontinued as of the end of

September 2024

IDF75E/IDFA75E: Scheduled to be discontinued as of the end of

September 2024

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) Proposal for the Use of a Separate Refrigerated Air Dryer

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) Proposal for the Use of a Separate Refrigerated Air Dryer

| Series | Rated inlet condition | Air flow capacity (m3/min[ANR]) 50 Hz | Air flow capacity (m3/min[ANR]) 60 Hz | Applicable air compressor (kW) | Refrigerant | Port size | Compressor output |

|---|---|---|---|---|---|---|---|

| IDF1E | 35℃ 0.7 MPa | 0.1 | 0.12 | 0.75 | R134a (HFC) | Rc3/8 | Less than 7.5kw |

| IDF2E | 35℃ 0.7 MPa | 0.2 | 0.235 | 1.5 | R134a (HFC) | Rc3/8 | Less than 7.5kw |

| IDF3E | 35℃ 0.7 MPa | 0.32 | 0.37 | 2.2 | R134a (HFC) | Rc3/8 | Less than 7.5kw |

| IDF4E | 35℃ 0.7 MPa | 0.52 | 0.57 | 3.7 | R134a (HFC) | Rc1/2 | Less than 7.5kw |

| IDF6E | 35℃ 0.7 MPa | 0.75 | 0.82 | 5.5 | R134a (HFC) | Rc3/4 | Less than 7.5kw |

| IDF8E | 35℃ 0.7 MPa | 1.22 | 1.32 | 7.5 | R134a (HFC) | Rc3/4 | Less than 7.5kw |

| IDF11E | 35℃ 0.7 MPa | 1.65 | 1.82 | 11 | R134a (HFC) | Rc3/4 | Less than 7.5kw |

| IDF15E1 | 35℃ 0.7 MPa | 2.8 | 3.1 | 15 | R134a (HFC) | Rc1 | Less than 7.5kw |

| IDF100F | 40℃ 0.7 MPa | 16.0 | 18.8 | 100 | R407C (HFC) | R2 | Less than 7.5kw |

| IDF125F | 40℃ 0.7 MPa | 20.1 | 23.7 | 125 | R407C (HFC) | 65(2 1/2B) flange | Less than 7.5kw |

| IDF150F | 40℃ 0.7 MPa | 25.0 | 30.0 | 150 | R407C (HFC) | 80(3B) flange | Less than 7.5kw |

| IDF190D | 40℃ 0.7 MPa | 32.0 | 38.0 | 190 | R407C (HFC) | 80(3B) flange | Less than 7.5kw |

| IDF240D | 40℃ 0.7 MPa | 43.0 | 50.0 | 240 | R407C (HFC) | 100(4B) flange | Less than 7.5kw |

| IDF370D | 35℃ 0.7 MPa | 54.0 | 65.0 | 370 | R407C (HFC) | 150(6B) flange | More than 7.5kw |

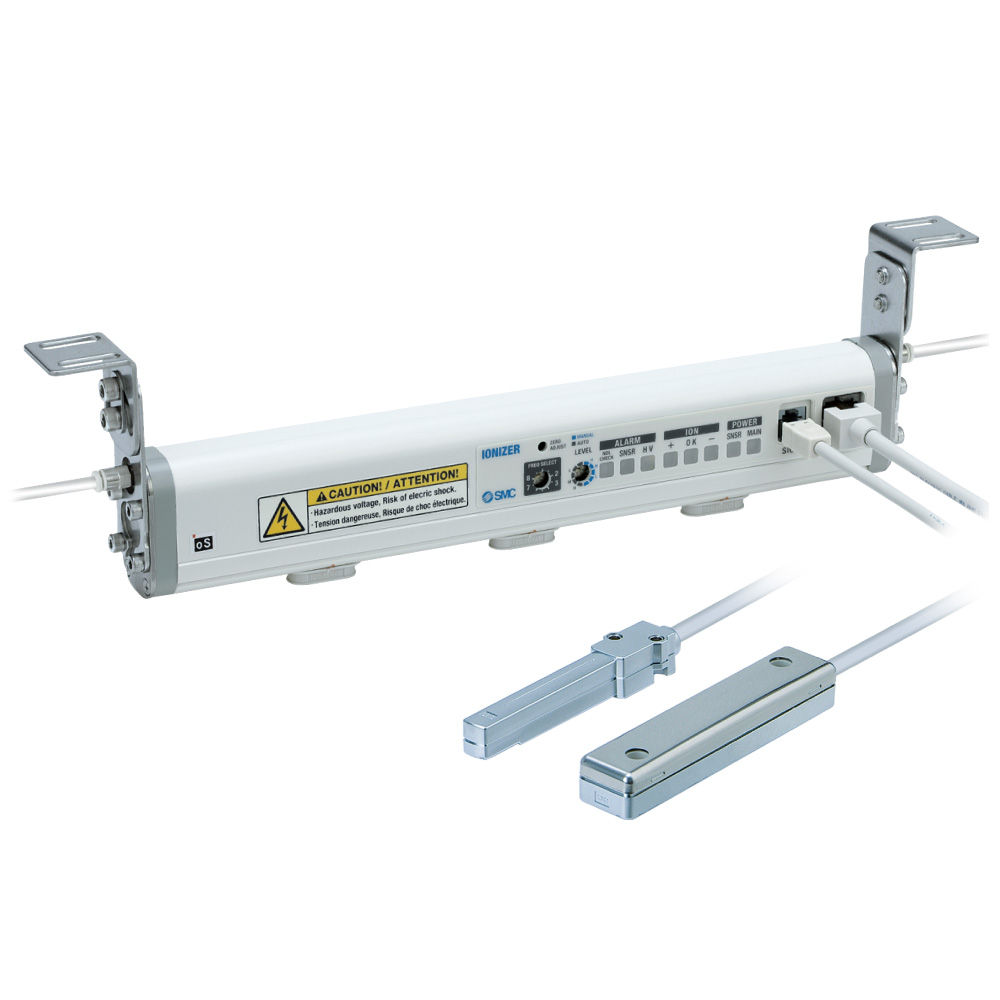

Ionizer IZS31

Static Neutralization Equipment » Static Neutralization Equipment Ionizer Bar Type

-

・Static neutralization time: 0.3 sec

・Select from 3 types of sensors.

・Rapid neutralization of static electricity by a feedback sensor

・Offset voltage control by an auto balance sensor

・High precision type: Accurately controls the offset voltage of the work position

・Body attachment type: Can be used while attached to the ionizer body by

detecting the earth return current

・The cartridge can be selected according to the application.

・The high-speed static neutralization type focuses on the speed of static neutralization.

・The low maintenance type improves the maintenance cycle.

| Series | Ion generation method | Ion balance |

|---|---|---|

| IZS31 | Corona discharge type | ±30 V (Stainless steel electrode needle : ±100 V) |

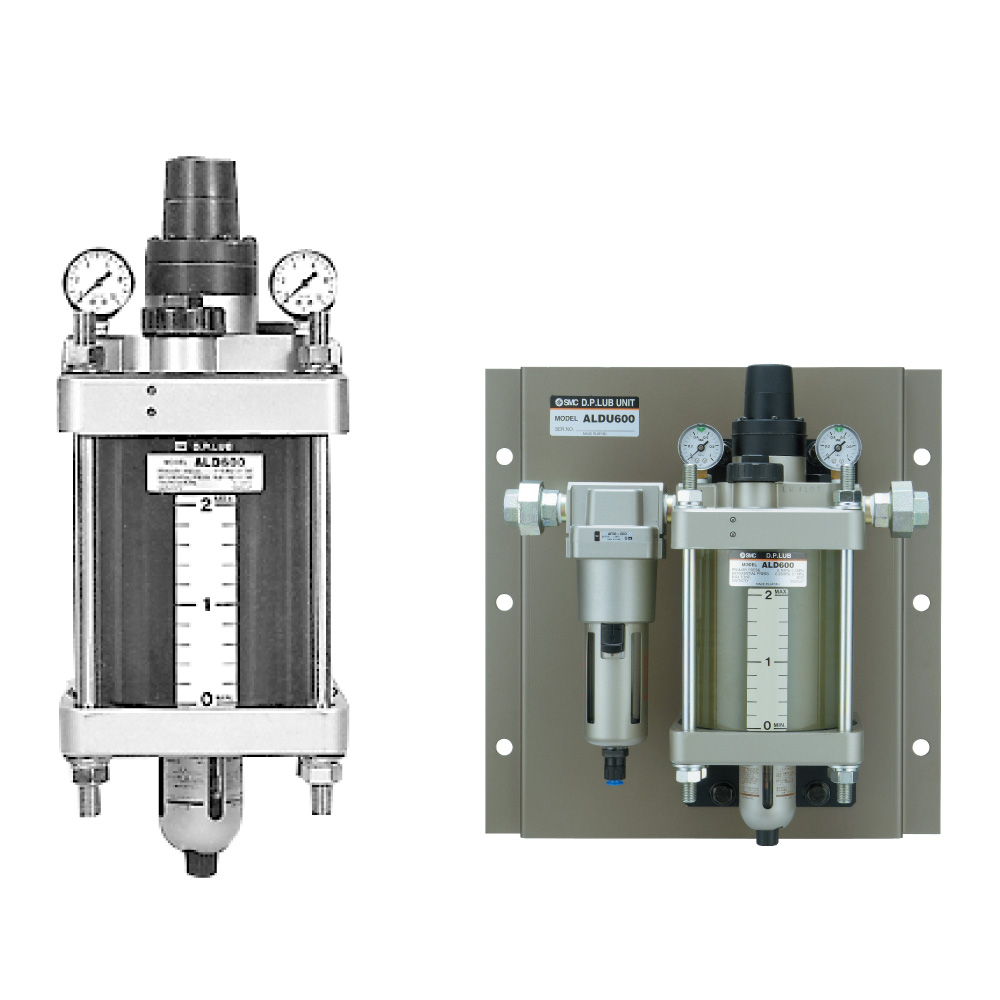

D.P. Lube ALD

Lubrication Equipment » Lubrication Equipment

-

・Centralized control of multi-point lubrication

・Less lubricant consumption

・Simplified oil feeding volume setting in which only the pressure differential is adjusted

・Oil can be replenished by merely opening and closing the oil filler plug without stopping the air line.

・Micromist generation can be checked from the oil filler port.

| Series | Type | Port size | Bowl capacity (cm3) |

|---|---|---|---|

| ALD600/900 | Single product | 3/4,1,1 1/4,1 1/2,2 | 2000,5000 |

| ALDU600/900 | Unit | 3/4,1,1 1/4,1 1/2,2 | 2000,5000 |