There were 21 hits in the keyword search.

In-line Type Vacuum Ejector ZU□A

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors-

・Compact and Lightweight

O.D.: ø10.4, Weight: 3.9 g, Overall length: 52 mm

・Port size

ø4, ø6 One-touch fitting, Rc1/8 female thread, ø5/32"

・Vacuum pressure reached [kPa]

Type S: -90, -87, -85

Type L: -48, -40

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] Type S | Max. suction flow [L/min(ANR)] Type L | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) |

|---|---|---|---|---|---|

| ZU03□A | 0.3 | 1.8 | 3.4 | 4.2 | 2 to 8 |

| ZU04□A | 0.4 | 3.2 | 5.8 | 7.7 | 2 to 10 |

| ZU05□A | 0.5 | 7 | 13 | 14 | 2 to 13 |

| ZU07□A | 0.7 | 11 | 16 | 28 | 2 to 20 |

Booster Lube ALB

Lubrication Equipment » Lubrication Equipment

-

・Centralized control of multi-point lubrication

・Stable oil feeding with a micromist

・Through the use of a booster, a pressure that is higher than that of the main air passage can be supplied. This difference is used as the mist

generating pressure differential. Thus, the pressure drop in the main air passage can be minimized.

・Micromist can be constantly supplied by merely adjusting the mist generating pressure differential.

・Oil can be replenished by merely opening and closing the oil filler plug without stopping the air line.

・Micromist generation can be checked from the oil filler port.

| Series | Type | Port size | Bowl capacity (cm3) |

|---|---|---|---|

| ALB900 | Booster lube | 1,2,3 | 5000 |

| ALBA90 | Bypass lubrication adapter | 1/4,1/2 | ー |

Compact Vacuum Unit (Vacuum Generators) ZB

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump SystemsIO-Link Devices » Vacuum Manifold

-

・Compatible with ejector systems and vacuum pump systems

・Quick response: Response time of the valve 5 ms, vacuum response time

28 ms

・Energy saving: Air consumption reduced by 17%, Vacuum pressure

reached increased by 21%

・Compact/Lightweight: 46 g

・With vacuum pressure switch

Can copy to up to 10 switches simultaneously

・IO-Link compatible

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZB03 | 0.3 | 2 | 3.5 | 2 to 8 | ZB00 |

| ZB04 | 0.4 | 3.5 | 6.5 | 2 to 10 | ZB00 |

| ZB05 | 0.5 | 4.5 | 10 | 2 to 13 | ZB00 |

| ZB06 | 0.6 | 7 | 18 | 2 to 20 | ZB00 |

Refrigerated Air Dryer/For Use in Europe, Asia and Oceania IDFA□E/□

Air Preparation Equipment » Air Dryers-

・Single-phase230VAC(50Hz), Three-phase400VAC, Three-phase380VAC

・For use in Europe/Low GWP Refrigerant Refrigerants: R1234yf(HFO), R454C(HFC)

・For use in Asia and Oceania Refrigerant: R134a (HFC), R410A (HFC)

* The production of the IDFA22E to IDFA75E series was scheduled to end

in June 2022, but will be extended. We will announce the production end

date separately.

Click here for the IDFA22E to IDFA75E series catalog.

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) EU/U.S. Refrigerant Regulation

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS) EU/U.S. Refrigerant Regulation

| Series | Rated inlet condition | Air flow capacity (m3/h [ANR] ) Outlet air pressure dew point 3℃ | Air flow capacity (m3/h [ANR] ) Outlet air pressure dew point 7℃ | Air flow capacity (m3/h [ANR] ) Outlet air pressure dew point 10℃ | Refrigerant | Port size |

|---|---|---|---|---|---|---|

| IDFA3E | 35℃ 0.7MPa | 12 | 15 | 17 | [For use in Europe] Low GWP refrigerant R1234yf(HFO) [For use in Asia and Oceania] R134a(HFC) | Rc3/8 |

| IDFA4E | 35℃ 0.7MPa | 24 | 31 | 34 | [For use in Europe] Low GWP refrigerant R1234yf(HFO) [For use in Asia and Oceania] R134a(HFC) | Rc1/2 |

| IDFA6E | 35℃ 0.7MPa | 36 | 46 | 50 | [For use in Europe] Low GWP refrigerant R1234yf(HFO) [For use in Asia and Oceania] R134a(HFC) | Rc3/4 |

| IDFA8E | 35℃ 0.7MPa | 65 | 83 | 91 | [For use in Europe] Low GWP refrigerant R1234yf(HFO) [For use in Asia and Oceania] R134a(HFC) | Rc3/4 |

| IDFA11E | 35℃ 0.7MPa | 80 | 101 | 112 | [For use in Europe] Low GWP refrigerant R1234yf(HFO) [For use in Asia and Oceania] R134a(HFC) | Rc3/4 |

| IDFA15E1 | 35℃ 0.7MPa | 120 | 152 | 168 | [For use in Europe] Low GWP refrigerant R1234yf(HFO) [For use in Asia and Oceania] R134a(HFC) | Rc1 |

| IDFA60 | 35℃ 0.7MPa | 204 | 300 | 360 | [For use in Europe] Low GWP refrigerant R454C(HFC) [For use in Asia and Oceania] R410A(HFC) | R1 |

| IDFA70 | 35℃ 0.7MPa | 312 | 408 | 480 | [For use in Europe] Low GWP refrigerant R454C(HFC) [For use in Asia and Oceania] R410A(HFC) | R1 1/2 |

| IDFA80 | 35℃ 0.7MPa | 552 | 654 | 720 | [For use in Europe] Low GWP refrigerant R454C(HFC) [For use in Asia and Oceania] R410A(HFC) | R2 |

| IDFA90 | 35℃ 0.7MPa | 810 | 900 | 960 | [For use in Europe] Low GWP refrigerant R454C(HFC) [For use in Asia and Oceania] R410A(HFC) | R2 |

Peltier-Type Chemical Thermo-con HED

Temperature Control Equipment » Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

-

・Heat exchanger for direct temperature control that uses a Peltier device

・Compatible with a wide range of chemical liquids through the use of a fluororesin

heat exchanger

・Compliant with CE-marking

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HED | 10 to 60℃ | 300 W, 500 W, 700 W, 900 W | ±0.1℃ | Peltier-type water-cooled | Deionized water, Fluorinated fluidAmmonia hydrogen peroxide solution, etc. |

Clean One-touch Fittings for Blowing KP

Fittings and Tubing » Fittings for Special Environments(Clean/Fluoropolymer)Clean Series/Low-Particle Generation » Fittings

-

・One-touch fittings for clean room blowing systems

・Completely oil-free (Fluoro-coated rubber portions)

・Wetted parts are non-metallic.

・Parts washed and assembled in a clean room, Packed in double packaging.

・Can be used in a vacuum (−100 kPa)

| Series | Applicable tubing O.D. | Connection thread |

|---|---|---|

| KP | φ4,φ6,φ8,φ10,φ12 | 1/8,1/4,3/8,1/2 |

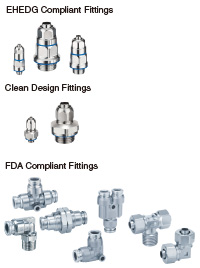

EHEDG Compliant/Clean Design/US FDA Compliant Fittings KFG2H□-E/KFG2H□-C/KQ□2-F・KFG2-F

Fittings and Tubing » Fittings for Special Environments-

・Hygienic design prevents liquid from accumulating after cleaning

・US FDA compliant materials

| Type | Series | Description | Thread type |

|---|---|---|---|

| EHEDG compliant | KFG2H□-E | Stainless steel 316 insert fittings | M,G |

| Clean design | KFG2H□-C | Stainless steel 316 insert fittings | M,G |

| FDA compliant | KQG2-F | Stainless steel 316 One-touch fittings | M,R,Rc, UNF,NPT G |

| FDA compliant | KQB2-F | Metal One-touch fittings | M,R,Rc, UNF,NPT G |

| FDA compliant | KFG2-F | Stainless steel 316 insert fittings | R,Rc, NPT G |

Digital Pressure Sensor GS40

Silencers/Exhaust Cleaners/Blow Guns/Pressure Gauges » Pressure GaugesSwitches/Sensors/Controller » Electronic Pressure Switches/Sensors (Self-contained Type)

-

・A pressure switch function has been added to the gauge with a digital

display.

*The GS40 Series digital pressure sensor is scheduled to be discontinued at

the end of August 2025.

Please select from the ISE20 Series of high-precision digital pressure

switches.

| Series | Set pressure (MPa) |

|---|---|

| GS40 | 0 to 0.98 |

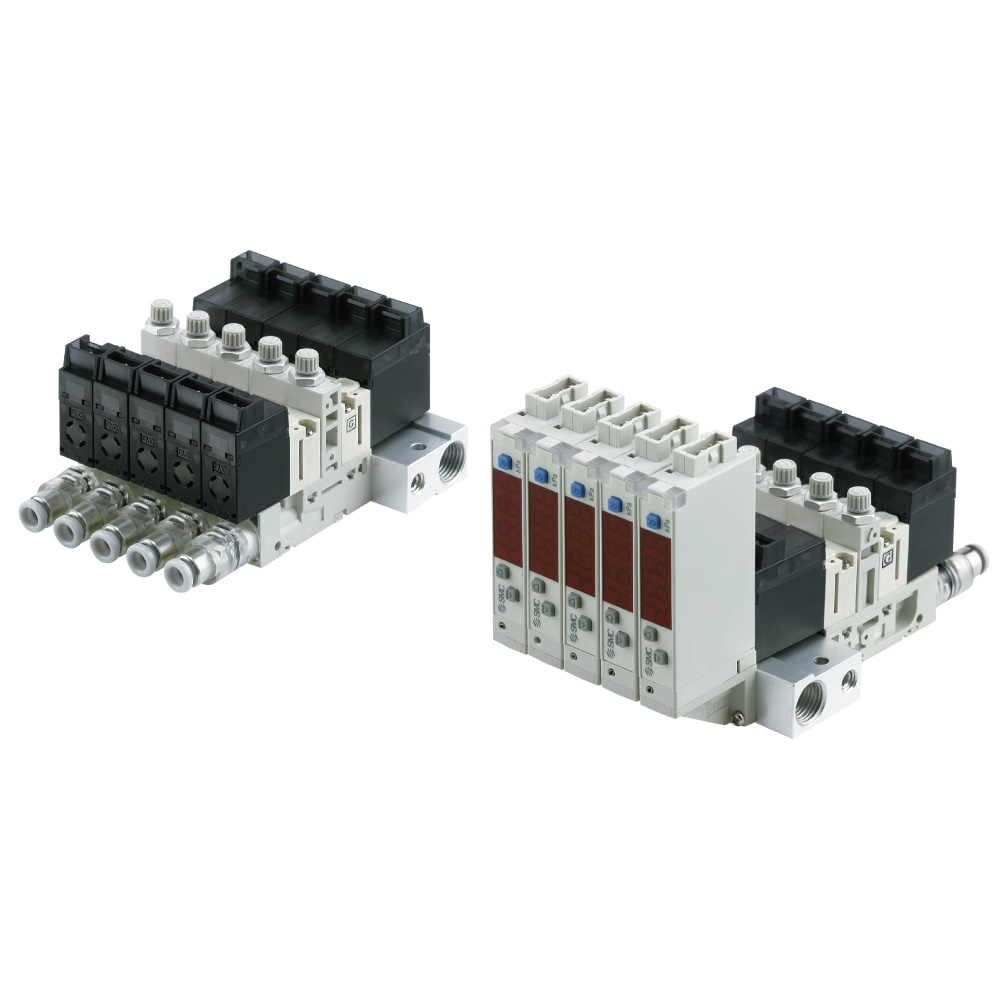

5-Port Solenoid Valve/Cassette Type Manifold SZ3000

Directional Control Valves » Pilot Operated 4/5 Port Solenoid Valves

-

・The cassette type allows for easy valve exchange.

・Valve has an attached switch for safe maintenance.

・The low-profile cassette type with baseless structure takes up less space.

・Manifold type no.: SS5Z3

*The EX510 series is to be discontinued. When designing new equipment

and facilities, consider using another series (EX260/EX600) instead.

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Flow rate characteristics 4/2→3(A/B→R) C[dm3/(s・bar)] | Flow rate characteristics 4/2→3(A/B→R) b | Flow rate characteristics 4/2→3(A/B→R) Cv | Applicable cylinder size | Power consumption (W) |

|---|---|---|---|---|---|

| SZ3000 | 0.77 | 0.19 | 0.19 | φ32 | 0.6 |

Vacuum Regulator IRV

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum RegulatorsModular F.R.L./Pressure Control Equipment » Regulators

Pressure Control Equipment » Regulators

-

・Allows for the adjustment of vacuum line pressure

・Single-sided connection series

・Weight reduced by 20% (Compared with the previous IRV2000 with IRV20 fitting)

・Built-in One-touch fittings

・The pressure gauge and digital pressure switch can be easily attached/detached due to being attached by a clip.

・Mounting direction of the pressure gauge and digital pressure switch can be changed. (Standard connections only)

・Mounting angle of the pressure gauge and digital pressure switch can be changed easily (in 60 degree increments).

Safety Instructions F.R.L. Units/Precautions Series Variations/Pressure Control Equipment

Product Selection Guide Green Procurement (RoHS)

Product Selection Guide Green Procurement (RoHS)

| Series | Port size | Set pressure range (kPa) |

|---|---|---|

| IRV10 | φ6,φ8,φ1/4,φ5/16 | -100 to -1.3 |

| IRV20 | φ6,φ8,φ10,φ1/4,φ5/16,φ3/8 | -100 to -1.3 |