There were 383 hits in the keyword search.

Manifold Controller JXD1-M□

Electric Actuators/Cylinders » Controllers/DriversElectric Actuators/Cylinders » Manifold Controller/Manifold Controller Compatible Electric Actuator

-

· Up to 16 axes can be connected

Max. 8 driver units can be connected

· Fanless design (no cooling fan)

No cooling fan = No need to worry about fan replacement

· Operating temperature range: 0 to 55°C

· Communication protocol

CC-Link

EtherNet/IP™

EtherCAT®

PROFINET®

· Cables, etc. can be attached from the front.

| Series | Compatible motor | Power supply voltage | Communication protocol | Connecting actuator | Number of driver units | Number of axes |

|---|---|---|---|---|---|---|

| JXD1-M□ | Battery-less absolute (Step motor 24 VDC) | 24 VDC ±10% | CC-Link EtherNet/IP™ therCAT® PROFINET® | LE2□ | Max. 8 units | Max. 16 axes |

Battery-less Absolute Encoder Type

[Compatible with Manifold Controller]

Electric Actuator/Rod Type LE2Y□H

Electric Actuators/Cylinders » Battery-less Absolute Encoder TypeElectric Actuators/Cylinders » Rod Type/Guide Rod Type

Electric Actuators/Cylinders » Manifold Controller/Manifold Controller Compatible Electric Actuator

-

· Compatible with manifold controller

· Annual CO2 emissions reduced by up to 38% through motor control

optimization (SMC comparison)

8.7 kg-CO2e/year (14.1)

∗ The numerical values vary depending on the operating conditions.

· Battery-less absolute encoder type

Restart from the last stop position is possible.

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions Green Procurement (RoHS)

| Specification | Model | Stroke (mm) | Work load (kg) Horizontal | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Battery-less absolute (Step motor 24 VDC) | LE2Y16□H | 30 to 300 | Max. 40 | Max. 700 | 2.5,5,10 |

| Battery-less absolute (Step motor 24 VDC) | LE2Y25□H | 30 to 400 | Max. 70 | Max. 900 | 3,6,12,20 |

| Battery-less absolute (Step motor 24 VDC) | LE2Y32□H | 50 to 500 | Max. 100 | Max. 900 | 4,8,16,24 |

Battery-less Absolute Encoder Type

[Compatible with Manifold Controller]

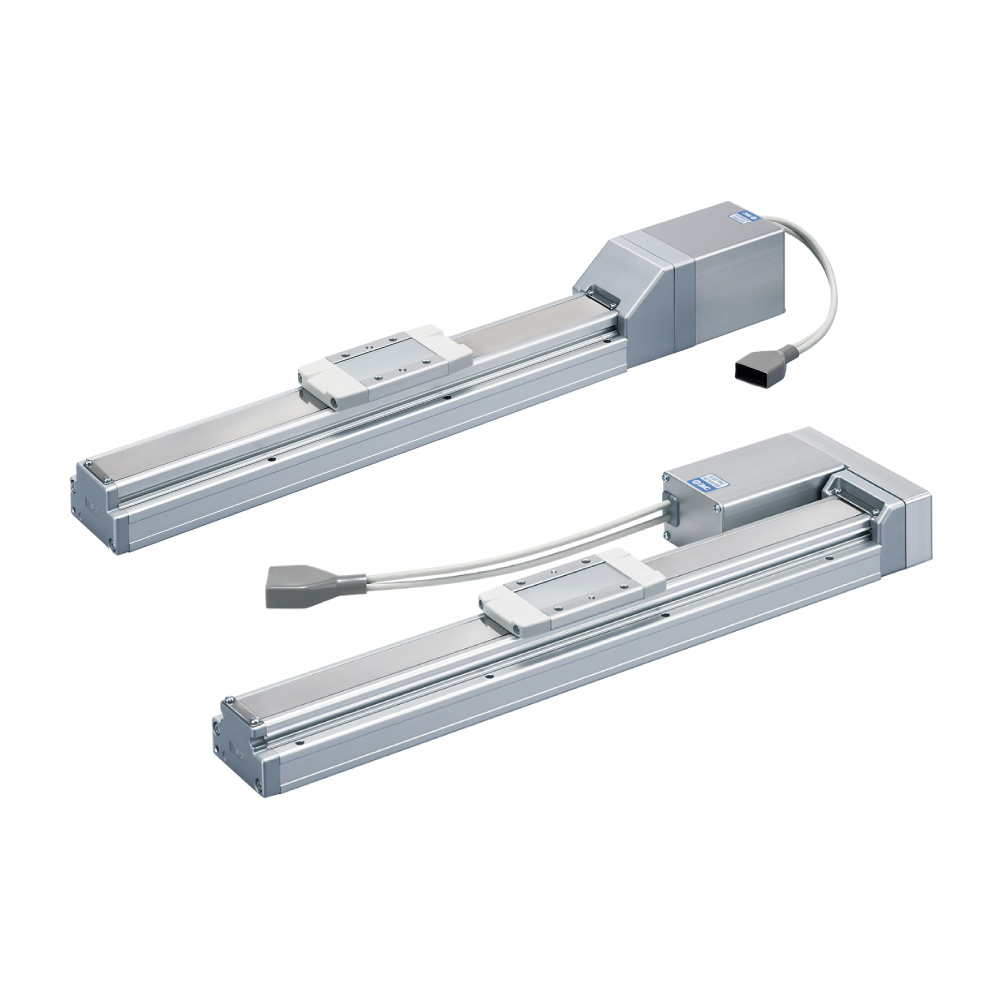

Electric Actuator/Slider LE2FS□H

Electric Actuators/Cylinders » Battery-less Absolute Encoder TypeElectric Actuators/Cylinders » Slider Type

Electric Actuators/Cylinders » Manifold Controller/Manifold Controller Compatible Electric Actuator

-

· Compatible with manifold controller

Up to 16 axes can be connected

· Annual CO2 emissions reduced by up to 38% through motor control

optimization (SMC comparison)

8.7 kg-CO2e/year (14.1)

∗ The numerical values vary depending on the operating conditions.

· Battery-less absolute encoder type

Restart from the last stop position is possible.

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions Green Procurement (RoHS)

| Specification | Model | Stroke (mm) | Work load (kg) Horizontal | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Battery-less absolute (Step motor 24 VDC) | LE2FS16□H | 50 to 500 | Max. 18 | Max. 800 | 2.5,5,10 |

| Battery-less absolute (Step motor 24 VDC) | LE2FS25□H | 50 to 800 | Max. 40 | Max. 1200 | 3,6,12,20 |

| Battery-less absolute (Step motor 24 VDC) | LE2FS32□H | 50 to 1000 | Max. 68 | Max. 1100 | 4,8,16,24 |

| Battery-less absolute (Step motor 24 VDC) | LE2FS40□H | 150 to 1200 | Max. 80 | Max. 1200 | 5,10,20,30 |

Electric Vacuum Gripper for Collaborative Robots ZXPE5

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Gripper for Collaborative RobotsElectric Actuators/Cylinders » Grippers for Collaborative Robots

Grippers for Collaborative Robots » Electric Vacuum Grippers (Built-in Vacuum Pump Type)

-

・A vacuum gripper that doesn't require an air source

・Operation possible by simply connecting an electrical wire connector

Can be used without an air source due to the built-in vacuum pump

・Unitization of the peripheral devices required for adsorption

The vacuum pump, atmospheric release valve, pressure monitor,

and cups have been integrated.

・Current consumption: Max. 64% reduction

Energy-saving operation possible via automatic/manual modes

・Lightweight: 556 g

・A wide variety of cup variations are available to support a wide range of

workpiece shapes.

・Standards: Conforming to ISO9409-1-50-4-M6

∗1 These are the values under SMC measurement conditions when the gripper is in continuous mode (the vacuum pump working continuously) and may vary depending on the

atmospheric pressure (weather, altitude, etc.) and the measurement method.

∗2 May be restricted depending on the cup diameter, mounting orientation, or workpiece. Please use within the max. work load. Suction and transfer exceeding the max. work load may result in product failure and the dropping of workpieces.

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Cup form | Cup diameter | Max. suction flow rate*1 [L/min(ANR)] | Max. work load*2

[Kg] |

|---|---|---|---|---|

| ZXPE5 | Flat Flat with rib Bellows Thin flat Multistage bellows 2.5-stage bellows 5.5-stage bellows Flat type for film packaging workpieces | φ8 to φ32 | 4.5 | 5 |

Analog Auto Switch and Display Sensor Monitor D-MH1□

Rotary Actuators/Air Grippers » Auto SwitchesSwitches/Sensors/Controller » Auto Switches for Rotary Actuators and Air Grippers

-

・Outputs the analog voltage according to the actuator stroke position

・A single switch can discriminate between max. 3 position points.

Repeatability: ±20 mV (Converted stroke ±0.1 mm)

Discriminable dimensional difference: 0.2 mm

∗ The value is in the high-resolution range. The converted stroke value

varies depending on the actuator.

∗ For air grippers, this is the value for one side of the finger. When it is

converted to the dimension of the workpiece to be gripped, the value is

doubled.

・Detection position display and setting away from the actuator are

possible.

・Analog voltage output (1 to 5 V)

・Can also be used with the analog auto switch single unit

・Reduced setting labor

・No need to fine-tune the switch mounting position

・Easy adjustment even in narrow places and on moving parts

・Improved productivity

· Gripper fully open R gripping R gripping failure detection

· Minimized lead wire disconnection risk

· Preventive maintenance

· Display of gripper finger wear

· Visualization of daily inspections (Origin position/ Gripping position)

| Series | Type | Description |

|---|---|---|

| D-MH1AD(V) | Analog auto switch | Analog output sensor (1 to 5 V) |

| D-MH1BN | Sensor monitor | Display sensor monitor, NPN 2 outputs |

| D-MH1BP | Sensor monitor | Display sensor monitor, PNP 2 outputs |

Non F-Gas Uses (CO2 Refrigerant) Thermo-chillers for the Semiconductor Industry INR-495-042/INR-495-043

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: DeviceNet Compatible Products

Temperature Control Equipment » Chiller Compliant Regulations

-

・Non F-Gas (CO2 refrigerant R744)

・GWP: 1 (Natural refrigerant)

・EU refrigerant regulations: GWP150 or less∗

・US refrigerant regulations: GWP700 or less∗

・California, US refrigerant regulations: GWP750 or less

∗As of December 2023

・Air transport possible

No air transport restrictions for non-toxic and non-flammable∗

refrigerants

∗A1 (ASHRAE34 standard)

・No F-Gas management required

Eliminates the need for periodic inspections based on the Fluorocarbon

Emissions Control Act (Japan)

・No F-Gas recovery & disposal costs

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| INR-495-042 INR-495-043 | -20 to 70 | 8.5 kW | ±1.0℃ | Water-cooled refrigeration | Fluorinated fluid |

Electric Gripper for Collaborative Robots LEHR

Electric Actuators/Cylinders » Grippers for Collaborative RobotsAir Gripper for Collaborative Robots » Electric Grippers

-

・Can be used with the collaborative robots of UNIVERSAL ROBOTS,

FANUC CORPORATION, and OMRON/TECHMAN ROBOT

・2 variations are available.

・Gripping force: 60 to 140 N

・Operate by simply connecting 1 electrical wire

・Annual CO2 emissions reduced by up to 52% through motor control

optimization (SMC comparison)

・With internal battery-less absolute encoder

・Easy tool changing (Manual changer)

・Compatible plug-in software: URCap

| Type | Series | Opening/Closing stroke [mm] | Gripping force [N] |

|---|---|---|---|

| For collaborative robots | LEHR | 50 | 60 to 140 |

Flow Controller for Air PFCA7

Switches/Sensors/Controller » Controllers-

・For the automatic adjustment of the flow rate

・Applicable fluid: Dry air, N₂, Ar, CO₂

・Color display/2-screen display supported

For the confirmation of the instantaneous flow rate, flow rate command

value, and accumulated flow rate at a glance

・IO-Link compatible

・Flow ratio 100:1

| Series | Rated control flow rate range [L/min] (Dry air, N₂, Ar) | Set control flow rate range [L/min] (Dry air, N₂, Ar) | Set control flow rate Min. unit [L/min] |

|---|---|---|---|

| PFCA710 | 0.1 to 10 | 0.04 to 10.3 | 0.01 |

| PFCA725 | 0.2 to 25 | 0.1 to 25.8 | 0.1 |

| PFCA750 | 0.5 to 50 | 0.2 to 51.5 | 0.1 |

| PFCA711 | 1 to 100 | 0.4 to 103 | 0.1 |

3-Screen Display Condensation Checker (Digital Temperature & Humidity Switch) PSH

Switches/Sensors/Controller » Electronic Temperature & Humidity Switches-

・A relative humidity under pressure (inside piping) display function has

been added. New

・A condensation checker can prevent such problems!

Allows for the visualization of humidity inside piping

Detects abnormalities prior to condensation generation

・Can be easily connected to any pipe you want to monitor

Compact size allows for easy installation

・Visualization of relative humidity

Real-time monitoring

・Remote/Condition monitoring

Remote confirmation via switch output preventing condensation

problems!

Safety Instructions Pressure Switches/Flow Switches/Precautions Pressure Switch Series Variations/Application Example Glossary of Terms/Technical Information Green Procurement (RoHS) Proposal for Condensation Checker Installation

| Series | Set temperature range | Set relative humidity range | Display accuracy |

|---|---|---|---|

| PSH | -5 to 55°C | 0 to 100% R.H. (No condensation) | Temperature: ±3°C ±1 digit Humidity: ±5% R.H. ±1 digit |

Electric Actuator/Large Slider Type, Belt Drive LET-X11

Electric Actuators/Cylinders » Slider Type-

・Max. work load: 240 kg (Size 100)/75 kg (Size 80)

・Stroke: Up to 3000 mm (Standard)

・Max. speed [mm/s]: 4000 (Size 100), 2160 (Size 80)

・Max. acceleration/deceleration [mm/s2]: 20000

・Simplified belt replacement

・Solid state auto switches are mountable.

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions Green Procurement (RoHS)

| Specification | Model | Stroke (mm) | Work load (kg) Horizontal | Speed (mm/s) | Equivalent lead (mm) |

|---|---|---|---|---|---|

| AC servo motor | LET80-X11 | 300 to 3000 | 75 | 2160 | 43.33, 26, 14.44 |

| AC servo motor | LET100-X11 | 300 to 3000 | 240 | 4000 | 80, 48, 26.67, 16 |