There were 1,276 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Refrigerated Air Dryer/Double Energy Saving Function Series IDF100FS/125FS/150FS

Air Preparation Equipment » Air Dryers-

・Energy-saving design (Second re-heater + Digital scroll compressor)

・Power consumption: Reduced by up to 76%

・Exhaust heat: Reduced by up to 25%

・Tolerant of high temperature environments!

・Ambient temperature: Up to 45ºC, Inlet air temperature: Up to 60ºC

Safety Instructions Air Preparation Equipment/Precautions

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

Model Selection Guide/Quick Reference Guide Green Procurement (RoHS)

| Series | Applicable compressor (kW) | Air flow capacity (m3/min[ANR]) 50 Hz | Air flow capacity (m3/min[ANR]) 60 Hz |

|---|---|---|---|

| IDF100FS | 100 | 16 | 18.8 |

| IDF125FS | 125 | 20.1 | 23.7 |

| IDF150FS | 150 | 25 | 27 |

Air Tank VBAT

Air Preparation Equipment » Aftercoolers/Air TanksModular F.R.L./Pressure Control Equipment » Booster Regulators

Booster Regulators » Booster Regulators

-

・Compact air tank that can be directly connected to a regulator

・Can be used as an independent tank

・With a safety valve port (Option)

・ It can be used alone as a tank.

・Overseas standards compliant products:

CE certified product (-Q)

ASME Standards compliant product (-X105)

Product not applicable to ASME Standards (-X11)

Chinese pressure vessel regulations compliant product (-X104)

Industrial Safety and Health Act KCs Certification compliant product

(-X101)

| Series | Port size | Tank capacity (L) |

|---|---|---|

| VBAT | 3/8,1/2,3/4 | 5,10,20,38 |

Drain Separator for Vacuum AMJ

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Related Equipment for Vacuum Systems

-

・Remove water droplets from the air by simply installing it in vacuum equipment connection lines.

・Effective for removing water droplets from the air sucked into vacuum pumps, ejectors, etc.

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Port size | Recommended flow rate (L/min) (ANR) | Max. operating pressure (MPa) | Water droplet removal ratio |

|---|---|---|---|---|

| AMJ | 1/4, 3/8, 1/2, 3/4, 1 | 200, 300, 500 | 1.0 | 90% |

Vacuum Gripper for Collaborative Robots ZXP7□4□-X1 for the OMRON Corporation and TECHMAN ROBOT Inc. TM/TM S Series

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Gripper for Collaborative RobotsAir Gripper for Collaborative Robots » Vacuum Grippers

-

・Plug and Play configuration for immediate use

TMComponent: Easy programming

・Operate by simply connecting 1 air supply tube and two electrical wiring

M8 connectors.

・Integrated vacuum ejector, air supply/release valve, pressure sensor, and

cups

・Standards: Conforming to ISO 9409-1-50-4-M6

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Cup form | Cup diameter | Suction flow rate [L/min(ANR)] | Air consumption [L/min(ANR)] |

|---|---|---|---|---|

| ZXP7□41-X1 ZXP7□42-X1 | Flat Flat with rib Bellows Thin flat Multistage bellows 2.5-stage bellows 5.5-stage bellows | φ8 to φ32 | 17 | 57 |

Magnet Gripper MHM

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Special PadsRotary Actuators/Air Grippers » Magnet Grippers

-

・Attracts and holds heavy objects with a magnet

・Holding force: Max. 1000 N (ø50, Workpiece thickness 6 mm)

・Transfers steel plates without a vacuum

Support workpieces with holes and uneven surfaces

・Holding force (Attraction force) can be adjusted.

・Drop prevention: Holds workpieces even when air is shut off

| Series | Max. holding force [N] (Workpiece thickness [mm]) |

|---|---|

| MHM-16 | 50(6) |

| MHM-25 | 200(6) |

| MHM-32 | 500(6) |

| MHM-50 | 1000(6) |

High Rigidity Vacuum Pad (Vacuum Suction Cup) ZP3E

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Pads (Vacuum Suction Cups)-

・Stable suction position, Improved ease of removal

・Pad form: Flat type with groove, Bellows type with ribs and groove

・Mounting: Male thread, Female thread

・Vacuum inlet direction: Vertical, Lateral

・Vacuum inlet: Male thread, Female thread

・Buffer Without, With

[Buffer stroke [mm]: 10, 30, 50]

Safety Instructions Vacuum Equipment/Precautions Vacuum Pads/Precautions Series Variations Model Selection Standard: Mounting Bracket Assembly (p.237-240) Ball Joint: Mounting Bracket Assembly (p.241-244) Green Procurement (RoHS)

| Series | Pad form | Pad diameter(mm) |

|---|---|---|

| ZP3E | Flat type with groove | φ32,φ40,φ50,φ63,φ80,φ100,φ125 |

| ZP3E | Flat type with groove (Ball joint type) | φ32,φ40,φ50,φ63,φ80,φ100,φ125 |

| ZP3E | Bellows type with ribs and groove | φ32,φ40,φ50,φ63,φ80,φ100,φ125 |

| ZP3E | Bellows type with ribs and groove (Ball joint) | φ32,φ40,φ50,φ63,φ80,φ100,φ125 |

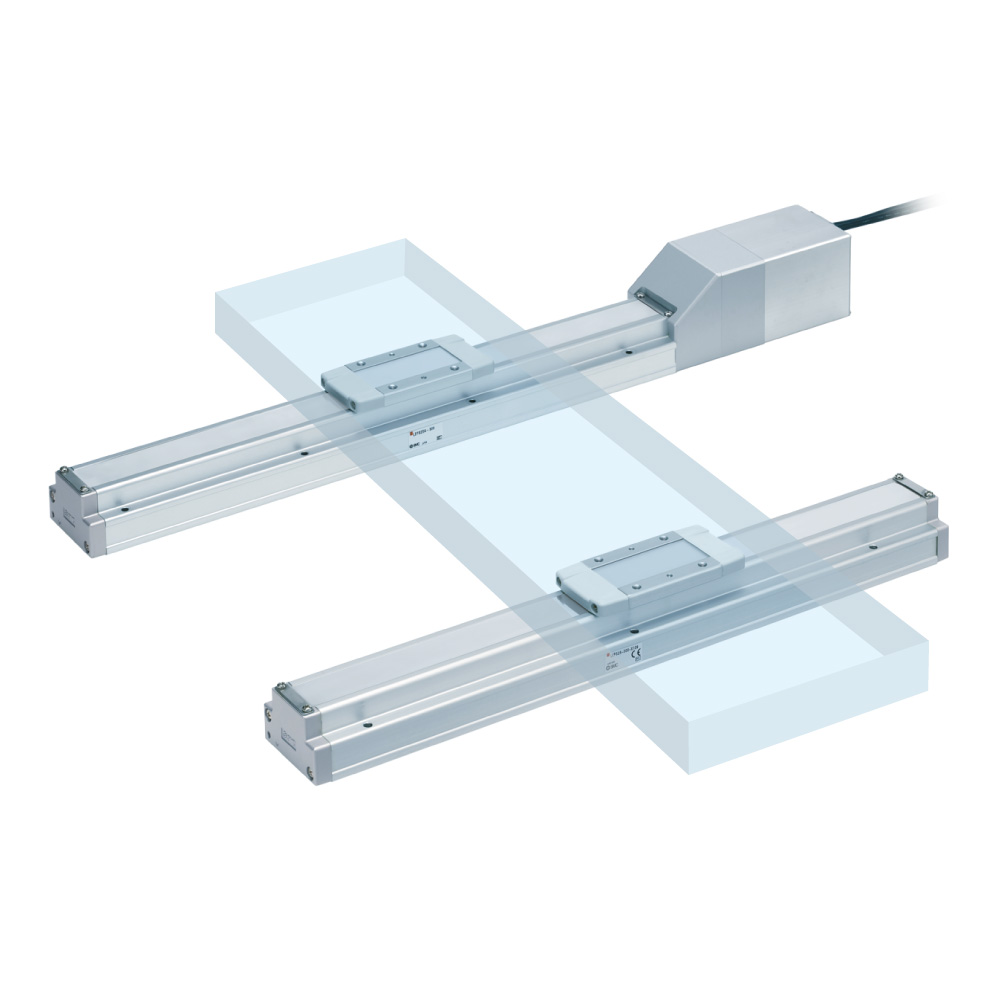

Electric Actuator: High Rigidity Slider Type LEJS63□-□M

Electric Actuators/Cylinders » Motorless Type-

・Built-in Intermediate Supports

・A maximum speed of 1,800 mm/s1 has been achieved throughout the entire stroke!

The use of intermediate supports results in reduced deflection of the ball screw when a long stroke is used.

・Max. stroke: 1,790 mm

・Horizontal work load: 85 kg (For the 10 mm lead)

・Positioning repeatability: ±0.01 mm (High-precision type)

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

| Spec. | Model | Stroke (mm) | Work load (kg) Horizontal | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Motorless Ball screw drive | LEJS63□-□M | 790 to 1790 | MAX.85 | MAX.1800 | 10,20,30 |

Electric Gripper 3-Finger Type (S Type) LEHS

Electric Actuators/Cylinders » Grippers

-

・Easy setting: Data can be set with only 2 items, position and force.

The controller is already set with the data of the actuator.

(The actuator and controller are provided as a set.)

・Equipped with a drop prevention function

(All series come equipped with a self-lock mechanism.)

・The self-lock mechanism reduces power consumption.

・Equipped with a gripping check function

・It is possible to set the position, speed, and force. (64 points)

Safety Instructions Electric Actuators/Precautions Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS) CE/UL-compliance List Actuator Cable I/O Cable

| Series | Body size | Open and close stroke/ both sides (mm) | Gripping force [N] Basic | Gripping force [N] Compact | Opening and closing speed (mm/s) |

|---|---|---|---|---|---|

| LEHS | 10 | 4 | 2.2 to 5.5 | 1.4 to 3.5 | 5 to 70 |

| LEHS | 20 | 6 | 9 to 22 | 7 to 17 | 5 to 80 |

| LEHS | 32 | 8 | 36 to 90 | ― | 5 to 100 |

| LEHS | 40 | 12 | 52 to 130 | ― | 5 to 120 |

Electric Actuator/LEF Series Support Guide LEFG

Electric Actuators/Cylinders » Slider Type

-

・A support guide that is designed to support workpieces with significant overhang

・Easy installation with the same outer dimensions as the LEF series body,

Contributes to the reduction of design and assembly labor

・The standardly equipped sealing band prevents the scattering of grease and the entry of foreign matter from outside.

Safety Instructions Electric Actuators/Precautions Features

Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

| Drive method | Model | Stroke (mm) |

|---|---|---|

| Ball screw drive/S | LEFG16-S | 50 to 500 |

| Ball screw drive/S | LEFG25-S | 50 to 800 |

| Ball screw drive/S | LEFG32-S | 50 to 1000 |

| Ball screw drive/S | LEFG40-S | 150 to 1200 |

| Belt drive/BT | LEFG16-BT | 300 to 1000 |

| Belt drive/BT | LEFG25-BT | 300 to 2000 |

| Belt drive/BT | LEFG32-BT | 300 to 2000 |

| Belt drive/BS | LEFG25-BS | 300 to 2000 |

| Belt drive/BS | LEFG32-BS | 300 to 2500 |

| Belt drive/BS | LEFG40-BS | 300 to 3000 |

Battery-less Absolute Encoder Type

Electric Actuator/Slider Type, Ball Screw Drive LEFS

Electric Actuators/Cylinders » Battery-less Absolute Encoder Type-

・Restart from the last stop position is possible.

・Easy operation restart after recovery of the power supply

The position information is held by the encoder even when the power supply is turned off.

A return to origin operation is not necessary when the power supply is recovered.

・No battery is installed. Reduced maintenance

No battery is used to store the position information.

There is no need to manage spare batteries or replacement maintenance.

・Max. work load: 65 kg

・Positioning repeatability: ±0.015 mm (High precision type)

Safety Instructions Electric Actuators/Precautions Auto Switches/Precautions

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

Features Series Variations Simplified Selection Flow Chart Green Procurement (RoHS)

| Specification | Model | Stroke (mm) | Work load (kg) Horizontal | Speed (mm/s) | Screw lead (mm) |

|---|---|---|---|---|---|

| Battery-less absolute (Step motor/24 VDC) | LEFS16 | 50 to 500 | Max. 15 | Max. 700 | 5,10 |

| Battery-less absolute (Step motor/24 VDC) | LEFS25 | 50 to 800 | Max. 30 | Max. 1100 | 6,12,20 |

| Battery-less absolute (Step motor/24 VDC) | LEFS32 | 50 to 1000 | Max. 50 | Max. 1200 | 8,16,24 |

| Battery-less absolute (Step motor/24 VDC) | LEFS40 | 150 to 1200 | Max. 65 | Max. 1200 | 10,20,30 |