There were 1,276 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Pilot Operated 3 Port Solenoid Valves HF1-/HF1A (Compatible) /HF1B (Compatible)

Equipment for the Food Manufacturing Industry » Directional Control Valves| Series | Model | Specification |

|---|---|---|

| 3-Port Solenoid Valve | HF1-VP300/500/700 | HF1 |

Pilot Operated 4/5 Port Solenoid Valves HF1-/HF1A (Compatible) /HF1B (Compatible)

Equipment for the Food Manufacturing Industry » Directional Control Valves| Series | Model | Specification |

|---|---|---|

| 5-Port Solenoid Valve/Plug-in Type | HF1-SY3000/5000/7000 | HF1 |

| 5-Port Solenoid Valve Body Ported/Single Unit | HF1-SY3000/5000/7000 | HF1 |

| Clean Design Manifold Valve Lead Wire Type | JSY5000-H | HF1B Compatible∗ |

Compact Position Sensor D-MPG

Air Cylinders » Actuator Position SensorIO-Link Compatible Products » Position Sensor

Industrial Device Communication Equipment/Wireless System » Industrial Device Communication Equipment: IO-Link Compatible Products

Rotary Actuators/Air Grippers » Position Sensor

Switches/Sensors/Controller » Position Sensor

-

・Detects the stroke position of compact actuators such as air grippers

・Repeatability: 0.1 mm

・Compact sensor head and separate teach unit

・Same shape as the D-M9□ solid state auto switch

・Analog output

・Switch output

・IO-Link compatible

▶IO-Link Devices

| Series | Measurement range | Resolution | Repeatability |

|---|---|---|---|

| D-MPG | 25 mm ±1 | 0.01 mm | 0.1 mm |

Magnet Buffer ZP3B□M

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Magnet Buffer-

· A new nut material has been added. [New]

· Stable buffer reaction force during stroke

· Adsorbs workpieces with different heights, Reduces the impact applied to

a workpiece

· Low particle generation

No particle generation due to the friction of a spring (spring-less

structure)

· Non-rotating

Reduces rotation by 4-pole magnets

· Copper and zinc-free

· Compatible with the secondary battery manufacturing process

| Series | Buffer size | Stroke |

|---|---|---|

| ZP3B1M | M8 x 0.75 | 3 mm,6 mm |

| ZP3B2M | M10 x 1.0 | 3mm,6mm |

| ZP3B3M | M12 x 1.0 | 3 mm,6 mm,16 mm |

Tool Changer One-push Type/Clamp Type RMTM

Grippers for Collaborative Robots » Air GrippersGrippers for Collaborative Robots » Tool Changer

-

·2 types of manual tool changers

· One-push Type

Tools can be attached/removed by the push of a button (no tools

required).

Work load: 10 kg

Repeatability: ±0.01 (Position reproducibility)

· Clamp Type

Tools can be attached/removed by clamper bolts (2 pcs).

Work load: 20 kg

Repeatability: ±0.02 (Position reproducibility)

·Standards: ISO9409-1-50-4-M6 compliant

Compatible with the flanges of most major collaborative robots

·Compact, Lightweight

| Type | Series | Work load (kg) | Repeatability (Position reproducibility) |

|---|---|---|---|

| One-push type | RMTM1 | 10 kg | ±0.01 |

| Clamp type | RMTM2 | 20 kg | ±0.02 |

Tool Changer/Auto Type RMTA

Grippers for Collaborative Robots » Air GrippersGrippers for Collaborative Robots » Tool Changer

-

·Robot hand tool automatic exchange

· Standards: ISO9409-1 compliant

Support for direct mounting on collaborative robots

· Robot and end tool connection/release

· More compact as flanges are not required.

Direct mounting on collaborative robots eliminates the need for flanges

and reduces design labor

·Supports a work load of up to 20 kg (Work load: 5 kg, 10 kg, 20 kg)

| Type | Series | Work load (kg) | Repeatability (Position reproducibility) |

|---|---|---|---|

| RMTA | Auto Type | 5,10,20 | ±0.01 |

Stainless Steel Throttle Valve with One-touch Fittings / In-line Type HF2B-ASG-□TV

Flow Control Equipment » Speed Controllers Special Environments-

・Improved corrosion/heat resistance with the all stainless steel exterior

Possible for use in environments such as high temperature, water splashing, and where copper and zinc cannot be used

・Material: Stainless steel 316 (External metal parts), FKM (Seal)

・Max. operating temperature: 150°C

・NSF H1 grease

・Fluid: Air, Water, N2

・Equipment for the food manufacturing industry HF2B- series

| Type | Series | Applicable tubing O.D. Metric size | Applicable tubing O.D. Inch size |

|---|---|---|---|

| Stainless steel throttle valve In-line type | HF2B-ASG-□TV | ø4 to ø12 | ø5/32" to ø1/2" |

High Speed/High Frequency Cylinder CM2/CQ2-X3423

Air Cylinders » Specialty Cylinders-

・ Maximum piston speed: 2500mm/s

・ Maximum operating frequency: 15Hz

・ Kinetic energy: 1.5 times (Compared with the standard product)

・ Reduced impact due to revision of cushion structure

・ Reduced weight of moving parts (piston rod, piston, etc.)

| 型式 | Series | Maximum piston speed | Maximum operating frequency | Bore size (mm) |

|---|---|---|---|---|

| Cylinder | CM2-X3423 | 2500mm/s | 12Hz (at 25 mm stroke) | 20, 25, 32 |

| Compact Cylinder | CQ2-X3423 | 2500mm/s | 15Hz (at 5 mm stroke) | 20, 25, 32 |

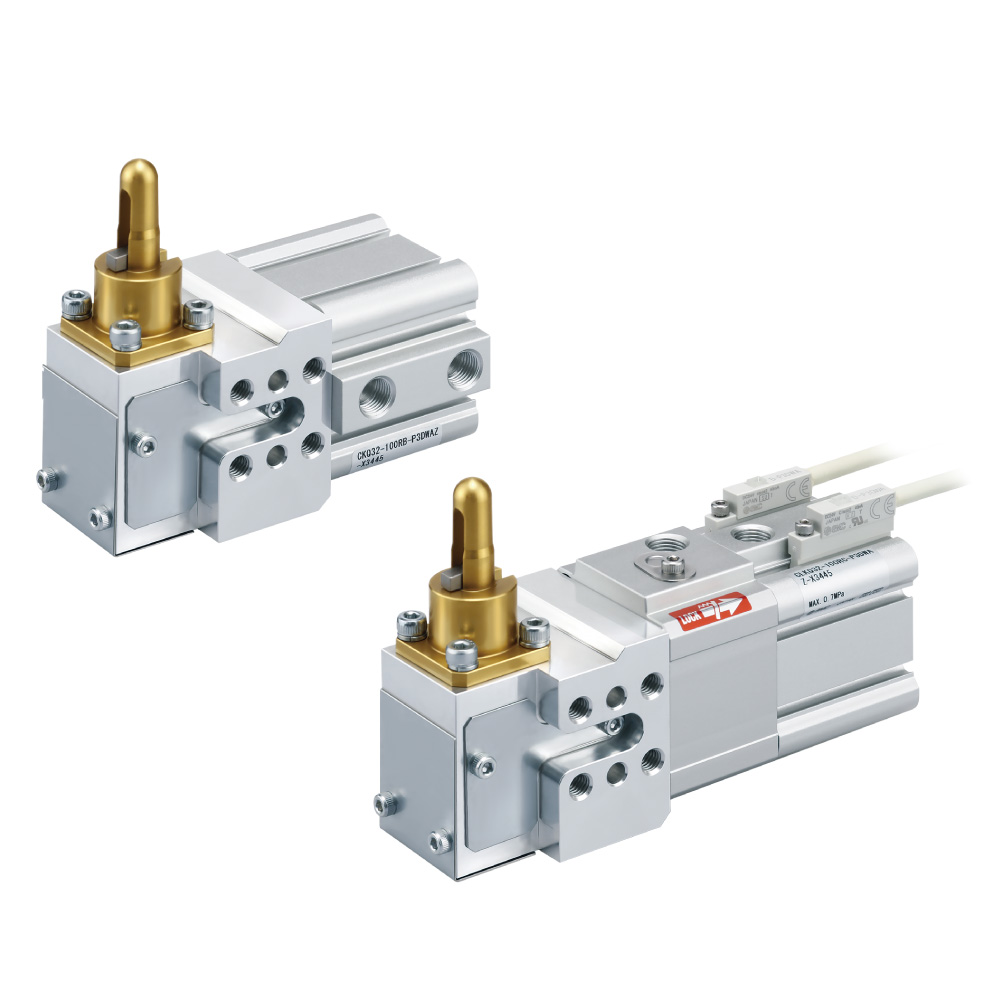

Pin Clamp Cylinder Lateral Compact Type C(L)KQ32-X3445

Air Cylinders » Clamp Cylinders-

・Lateral Compact Type

・Compact: Overall length: 94 mm shorter (183mm→89mm)∗

・Lightweight: Weight: 38% reduction (900g→560g)∗

∗ Compared with the existing product CKQG32-X2081, LOW type, without

lock

・Lock mechanism to prevent the dropping of workpieces during

emergency stops

・Various clamp arm positions and port positions are available.

・Mountable on 2 surfaces

Safety Instructions Actuators/Precautions Auto Switches/Precautions

Model Selection/Technical Data Green Procurement (RoHS)

Model Selection/Technical Data Green Procurement (RoHS)

| Type | Series | Guide pin shape | Bore size(mm) |

|---|---|---|---|

| Lateral Compact Type Without lock | CKQ32-X3445 | Round type Diamond type | 32 |

| Lateral Compact Type With lock | CLKQ32-X3445 | Round type Diamond type | 32 |

[Low GWP Refrigerant Chiller] Thermo-chiller/Rack Mount Type HRRF

Temperature Control Equipment » Chiller Compliant Regulations-

・Low GWP refrigerant chiller

GWP: 146∗ ∗ Regulation (EU) 2024/573, AIM Act 40 CFR Part 84

EU refrigerant regulations: GWP150 or more

US refrigerant regulations: GWP700 or more

California, US refrigerant regulations: GWP750 or more

・Environmentally friendly R454C as refrigerant (Not available for air

transport)

・Operable without the need to remove the unit from the rack

Front access: Simple to control, service, and maintain with all filters and

drainage accessible via the front panel

・Space saving: Multiple chillers can be mounted to a 19-inch rack.

・Cooling capacity: 1.2/1.8 kW (60 Hz)

・Temperature stability: ±0.1°C

・Power supply: Single-phase 200 to 230 VAC (50/60 Hz)

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRRF012 | 5 to 35℃ | 1.0kW/1.2kW (50/60Hz) | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water, 15% ethylene glycol aqueous solution |

| HRRF018 | 5 to 35℃ | 1.6kW/1.8kW (50/60Hz) | ±0.1℃ | Air-cooled refrigeration Water-cooled refrigeration | Tap water, 15% ethylene glycol aqueous solution |