There were 318 hits in the keyword search.

Discontinued products is also a hit. Click here for details.

Mechanical Valve VM/VZM/VFM

Directional Control Valves » Mechanical Valves/Transmitters-

・A wide variety of valves are available for all types of air systems.

・Small mounting space with a compact body

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Series Variation Selection/Technical Data Green Procurement (RoHS)

| Description | Series | Number of ports |

|---|---|---|

| Mechanical valve | VM1000 | 2/3 ports |

| Mechanical valve | VM100,VM200 | 2/3 ports |

| Mechanical valve | VM400 | 3 ports |

| Mechanical valve | VZM500,VZM400 | 5 ports |

| Mechanical valve | VFM300,VFM200 | 5 ports |

| Mechanical valve | VM800 | 3 ports |

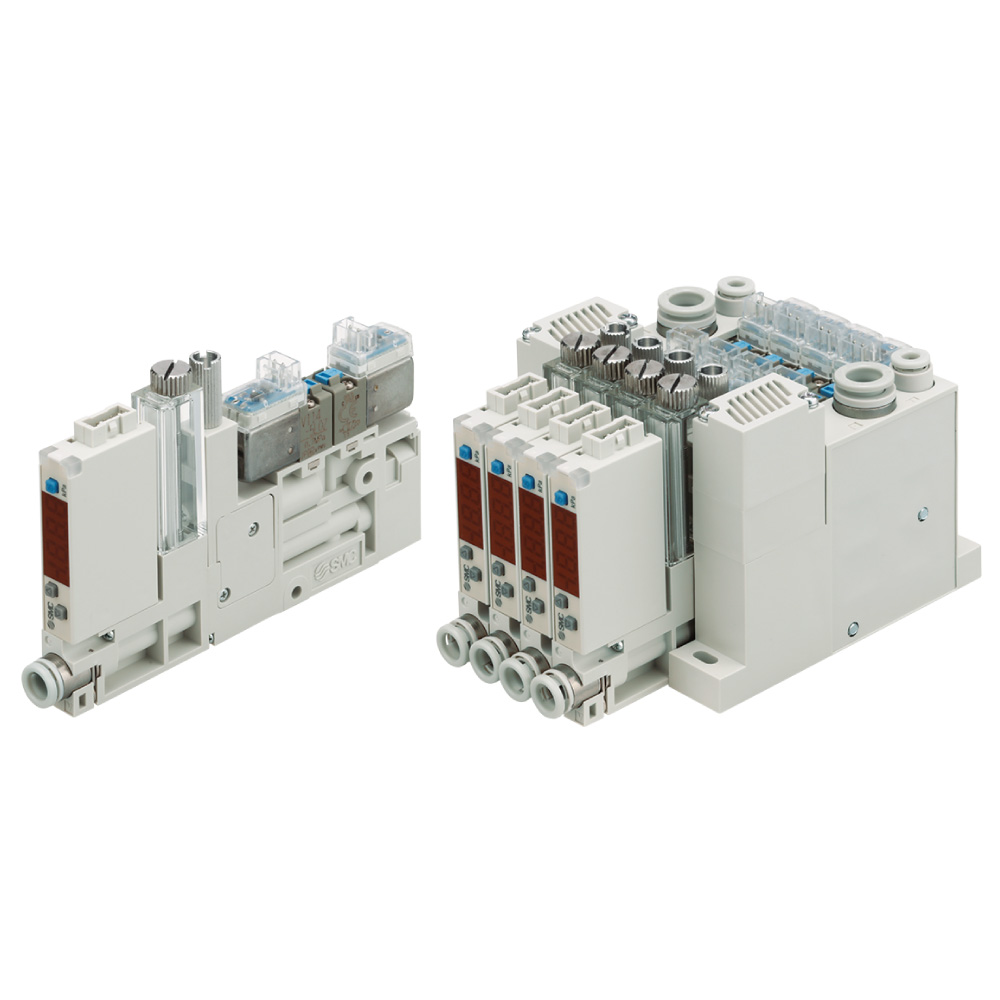

3-Port Solenoid Valve/Highly Integrated Unit Manifold VV100

Directional Control Valves » Direct Operated 3/4/5 Port Solenoid Valves

-

・Compact manifold with two 3-port valves on 1 station

・Connector (For plug-in connection)

・Individually wired valves can be added.

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Series | Flow rate characteristics 2a/2b→3(E) C[dm3/(s・bar)] | Flow rate characteristics 2a/2b→3(E) b | Power consumption (W) | For use in vacuum applications |

|---|---|---|---|---|

| VV100 | 0.05 | 0.29 | 0.4(Standard) 0.15(With power saving circuit) | -100 kPa |

Lever Hand Valve VHL

Directional Control Valves » Finger Valve/Hand Valves/Residual Relief 3 Port Valve-

・Space saving, Easy to operate (Vertical type) 5-port lever valve

・Weight reduction of up to 45%

∗ Comparison between VHL21□D-02□ and VH210-□02

・Footprint reduced by 58%

VHL210D 3216.5 mm2 ⬅ VH20□ 7750 mm2

・Panel mounting internal height reduced by 18.6 mm

For panel mounting

∗ Comparison between VHL210D and the existing VH20□ model

・Flow rate increased by 73%

∗ Comparison between VH211□-02□ and VH210-□02

(Flow rate characteristics 1 → 4/2 (P → A/B))

・3 operation types

Safety Instructions 3/4/5 Port Solenoid Valves/Precautions Selection/Technical Data

Green Procurement (RoHS)

Green Procurement (RoHS)

| Description | Series | Operation type | Port size |

|---|---|---|---|

| Lever hand valve | VHL | Spring return Detent Detent type with shift prevention lock | 1/4 |

Air Gripper for Collaborative Robots/Standard Type RMHZ2

Rotary Actuators/Air Grippers » Parallel Type Air GrippersRotary Actuators/Air Grippers » Air Gripper Unit for Collaborative Robots

Air Gripper for Collaborative Robots » Air Grippers

-

・Unitization of the peripheral devices required for gripper driving

Operation is possible simply by connecting 1 air supply tube and 1

electrical wire.

Built-in solenoid valve, exhaust throttle valve with silencer, auto switch,

fitting, etc.

・Can be used with the collaborative robots of 12 companies

UNIVERSAL ROBOTS, OMRON/TECHMAN ROBOT, FANUC, YASKAWA

Electric, Mitsubishi Electric, HAN’S ROBOT, KUKA, DOOSAN ROBOTICS,

SIASUN, JAKA, AUBO, ABB

・Manual changer built in as standard

Allows for easy tool changing and labor saving

・Air consumption reduced by up to 80%

・High rigidity and precision are achieved by integrating the guide and

finger.

・With high-precision linear guide

| Series | Number of fingers | External gripping force [N] | Internal gripping force [N] | Opening/Closing stroke (Both sides) [mm] |

|---|---|---|---|---|

| RMHZ2 | 2 | 54.2 | 72.2 | 14 |

Compact Type Speed Controller with Indicator JAS-S

Flow Control Equipment » Speed Controllers for General Purposes-

・Height: Max. 20.8 mm shorter

・Flow rate can be controlled numerically with the indicator window.

Due to the vernier indication, it is possible to configure fine settings in 1/4

increments.

Reduces work-hours and setting mistakes

・Mounting stud is available on the left side or the right side.

| Type | Series | Port size on the cylinder side | Applicable tubing O.D. Metric size | Applicable tubing O.D. Inch size |

|---|---|---|---|---|

| Elbow type | JAS-S | M3×0.5 M5×0.8 10-32UNF R, NPT, G 1/8 | φ3.2,φ4,φ6 | φ1/8'',φ5/32'',φ1/4'' |

Hexagon Wrench Adjustable Metal Speed Controller with Indicator ASB-□H

Flow Control Equipment » Tool Operation Type Speed Controllers-

・Improved environmental resistance with the all metal exterior [With

indicator]

For use in environment with welding spatter (Option BH type)

Contributes to reducing setting time and errors by allowing the user to

adjust flow rate before mounting and operating the cylinder

・Possible to manage the flow rate values using an indicator!

・Flow adjustable with a hexagon wrench tool

Prevents accidental manual operation

・Adjustment needle lock nut feature as standard

Prevents unauthorized adjustment and unwanted operation of the

needle from the set position due to vibrations or impacts.

Helps improve safety in your machinery.

・2 types are available for different applications.

For welding environments and for general environments

| Type | Series | Port size on the cylinder side | Applicable tubing O.D. Metric size | Applicable tubing O.D. Inch size |

|---|---|---|---|---|

| Metal body, Elbow type | ASB-□H | M5×0.8 10-32UNF R, G, NPT 1/8 to 1/2 | φ4 to φ12 | φ5/32'' to φ1/2'' |

Compact Vacuum Unit ZQ□A

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Vacuum Ejectors (Vacuum Generators)/Vacuum Pump SystemsIO-Link Devices » Vacuum Manifold

-

・Vacuum pressure switch with energy saving function

Air consumption: 90% reduction (Based on SMC’s measurement

conditions)

Power consumption: 60% reduction [1 W (Existing model) → 0.4 W]

Vacuum release pressure: From 0 MPa [From 0.3 MPa (Existing model) →

From 0 MPa]

Copy function: Reduced setting labor, Minimized risk of setting mistakes

・Compatible with ejector systems and vacuum pump systems

・IO-Link compatible

Safety Instructions Vacuum Equipment/Precautions Series Variations/Model Selection

Green Procurement (RoHS)

Green Procurement (RoHS)

| Ejector series | Nozzle diameter (mm) | Max. suction flow [L/min(ANR)] | Air consumption [L/min(ANR)] | Guidelines for applicable pad (mm) | Vacuum pump system series |

|---|---|---|---|---|---|

| ZQ05 | 0.5 | 5 | 15 | 2 to 13 | ZQ000□ |

| ZQ07 | 0.7 | 10 | 25 | 2 to 20 | ZQ000□ |

| ZQ10 | 1.0 | 22 | 47 | 2 to 32 | ZQ000□ |

NAMUR Interface 3/5-Port Solenoid Valve IP67 Compliant, Hygienic Design Type VFN2120N-X23/-X36

Pneumatic Instrumentation Equipment » Solenoid Valves

-

・A hygienic design has been adopted.

Resin body with less concaves

Direct cleaning of the valve is possible. (IP67)

・3-port/5-port valves are available.

Due to the function plate, 3/5-port valves are selectable.

・Low power consumption

Power consumption: 0.5 W

・Port threads: NPT1/4, G1/4

| Series | Flow rate characteristics (Cv/Effective area) | Manual override | Type of coil insulation | Power consumption (W) |

|---|---|---|---|---|

| VFN2120N-X23/-X36 | 0.8/11mm2 | Push type Locking type (Tool required) Locking type (Manual type) | Class B | 0.5 |

Aluminum High Vacuum Angle Valve XL□

High Vacuum Equipment » High Vacuum Valves-

・High fluorine resistance

・Minimal outgassing

・Minimal contamination from heavy metals

∗ The XLA(V)/C/F(V)/G with flange sizes of 16 to 80 has been

discontinued in September 2017.

Please select the XLA(V)-2/XLC-2/XLF(V)-2/XLG-2 series.

Safety Instructions System Configuration/Role of Each Line and Component Series Variations Glossary Auto Switches Common Specifications Green Procurement (RoHS)

| Series | Actuation | Valve type | Shaft seal type | Application | Flange size |

|---|---|---|---|---|---|

| XLA | Air operated | Single acting (N.C.) | Bellows seal | Dust-free Cleaned | 16 to 160 |

| XLAV (With solenoid valve) | Air operated | Single acting (N.C.) | Bellows seal | Dust-free Cleaned | 16 to 160 |

| XLC | Air operated | Double acting | Bellows seal | Dust-free Cleaned | 16 to 160 |

| XLCV (With solenoid valve) | Air operated | Double acting | Bellows seal | Dust-free Cleaned | 16 to 80 |

| XLF | Air operated | Single acting (N.C.) | O-ring seal | High-speed operation High operating cycles | 16 to 160 |

| XLFV (With solenoid valve) | Air operated | Single acting (N.C.) | O-ring seal | High-speed operation High operating cycles | 16 to 160 |

| XLG | Air operated | Double acting | O-ring seal | High-speed operation High operating cycles | 16 to 160 |

| XLGV (With solenoid valve) | Air operated | Double acting | O-ring seal | High-speed operation High operating cycles | 16 to 80 |

| XLD | Air operated | Single acting (N.C.) | Bellows/O-ring seal | For preventing dust turbulence For preventing a pump from running overloaded | 25 to 160 |

| XLDV (With solenoid valve) | Air operated | Single acting (N.C.) | Bellows/O-ring seal | For preventing dust turbulence For preventing a pump from running overloaded | 25 to 160 |

| XLH | Manual | Manual | Bellows seal | Dust-free Cleaned | 16 to 50 |

| XLS | Electromagnetic | Single acting (N.C.) | (Bellows balance) | For portable equipment not requiring air | 16, 25 |

Thermo-chiller/Environmentally Resistant Type HRS-R

Industrial Device Communication Equipment/Wireless System » Other: RS485 Compatible ProductsIndustrial Device Communication Equipment/Wireless System » Other: RS232C Compatible Products

Temperature Control Equipment » Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

-

・Resistant to dust and water splashing

・Protection of the electrical unit: IP54

・Metal panel

The entire exterior surface is metal.

A stainless steel panel can be selected. (Option)

・A large capacity tank (12 L) is available. (Option)

・Ambient temperature: 5 to 45°C

Safety Instructions Temperature Control Equipment/Precautions Features/Series Variations

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

Technical Data Temperature Control Equipment Warranty Green Procurement (RoHS)

| Series | Set temperature range | Cooling capacity | Temperature stability | Cooling method | Circulating fluid |

|---|---|---|---|---|---|

| HRS-R | 5 to 40℃ | 1.9 kW 2.9 kW 5 kW (60 Hz) | ±0.1℃ | Air-cooled refrigeration | Tap water Ethylene glycol aqueous solution (15%) |